Self-slag-removal storage tank and accumulated slag cleaning method thereof

A slag accumulation and self-cleaning technology, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems such as the lack of cleaning methods for tar and ammonia water storage tanks, and achieve the effect of solving safety problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below, the present invention will be described in further detail in conjunction with the accompanying drawings.

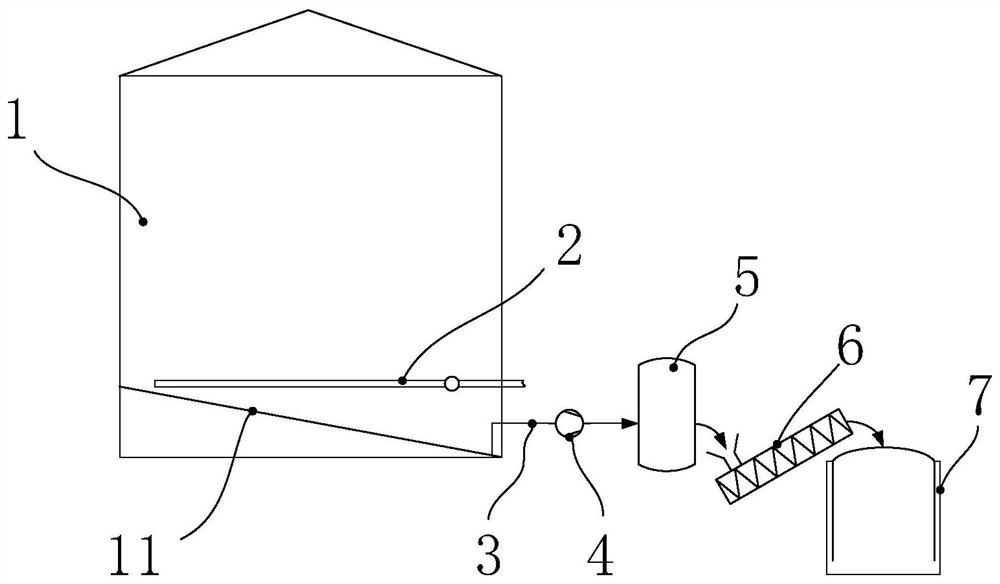

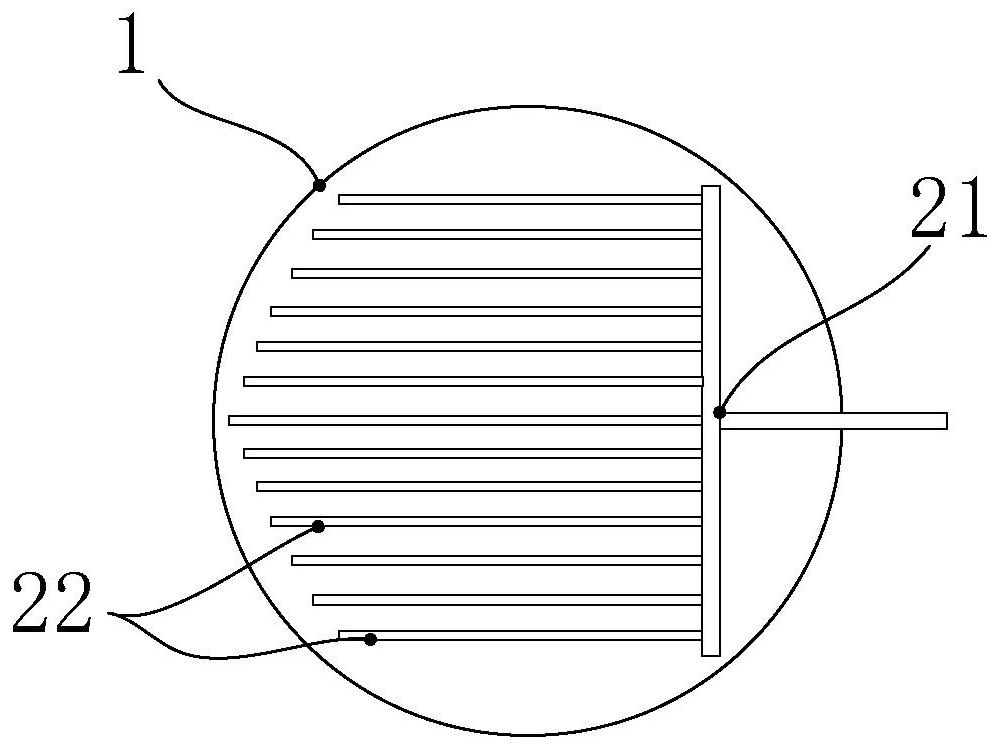

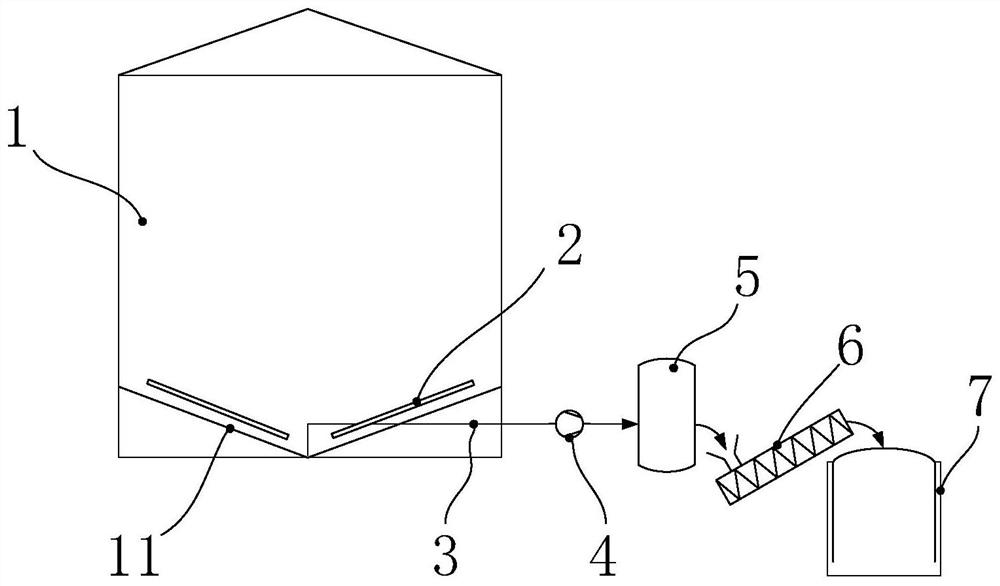

[0019] Such as Figure 1-2 As shown, in Embodiment 1, the bottom surface 11 adopts a one-sided inclination method, that is to say, the bottom surface 11 is a plane, which slopes downward from one side of the tank body 1 to the other side, so that the slag accumulation will move toward the lower side. Side accumulation forms a subsidence slag area. The air intake direction of the flushing device extends from the lower side to the higher side. The medium conveying main pipe 21 is T-shaped, and the air intake end is inserted into the tank from the side wall of the tank body 1. The flushing pipe 22 is arranged to extend horizontally from above the sedimentation slag accumulation area to the non-sedimentation area. Since the tank body 1 is cylindrical, the length of each flushing pipe 22 is determined according to its distance from the opposite side wall, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com