Truck-mounted self-loading and self-unloading forklift with weighing function

A forklift and weighing technology, applied in the direction of weighing, lifting devices, measuring devices, etc., can solve the problems that small forklifts cannot be carried with the truck, and cannot complete the loading and unloading of large items, and achieve strong practicability, simple manufacture, and overcome The effect of a single function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]The present invention will be further described below with reference to the drawings and embodiments.

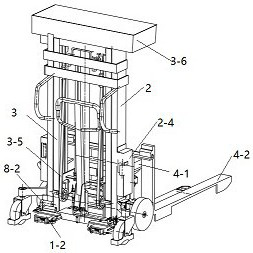

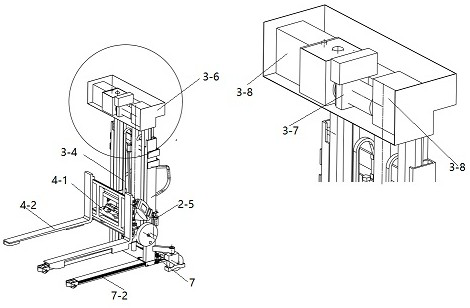

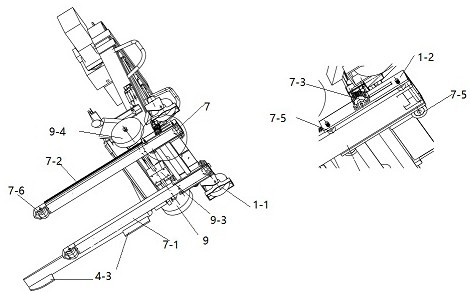

[0023]The present invention includes that one end of the forklift underframe 1 is provided with the first frame mechanism 2 and the second frame mechanism 3; the rear end of the forklift underframe 1 is provided with the rear foot universal wheel 1-1 and pushing The handle 1-3, the pushing handle 1-3 is arranged at the lower end of the forklift chassis 1, one end of the pushing handle 1-3 is rotatably connected with the lower end of the forklift chassis 1; the forklift chassis 1 The bottom end is provided with a bottomless square seat 1-2, and the bottomless square seat 1-2 is provided with a movable outrigger telescopic mechanism including movable legs 7-1. The two sides of the bottomless square seat 1-2 There are square slots, and the two sides of the rear end of the movable leg 7-1 are also provided with square slots, and they are aligned with the square slots on both sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com