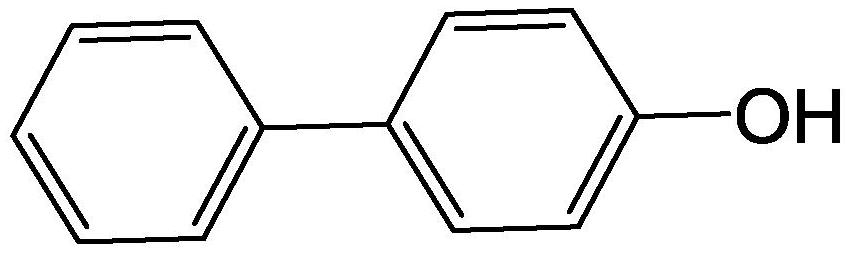

Synthesis of diphenols

A technology for biphenol and synthesis process, applied in the field of biphenol synthesis technology, can solve problems such as unsatisfactory purity and yield, difficulty in handling, difficult production environment, etc., and achieve the effects of high industrialization value, simple method and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

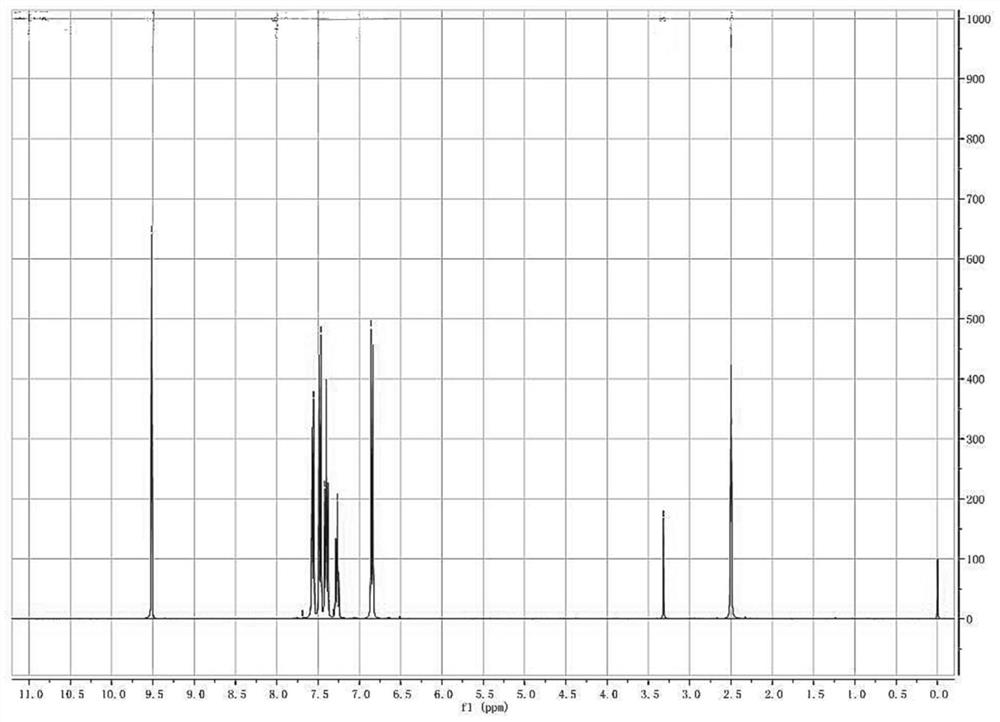

Image

Examples

Embodiment 1

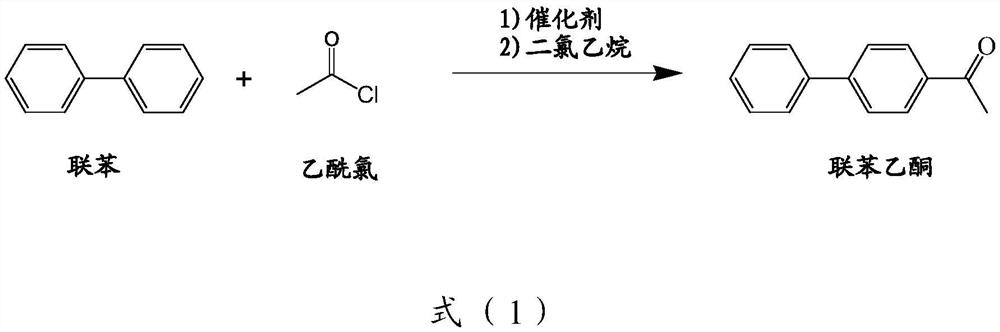

[0109] Add 150ml of dichloroethane, 30.8g of biphenyl and 15.7g of acetyl chloride into a 500ml four-neck flask, add 28.8g of aluminum trichloride in batches under ice cooling, and control the temperature between 0-10°C. Continue stirring for 0.5 hours after the addition, remove the ice bath, naturally warm up to room temperature and continue stirring for 0.5 hours, and monitor the liquid phase. After the reaction, the resulting solution was poured into 150 ml of ice water, stirred for 20 min, and allowed to stand to separate layers. The lower layer was washed with water, about 1 / 3 of the organic layer was evaporated, and the remaining residue was directly used for the next reaction.

[0110] Add the solution after the reaction treatment in the previous step, 40g of maleic anhydride, and 100ml of dichloroethane into a 500ml four-necked bottle, lower the temperature below 10°C, add 27.2g of 50% hydrogen peroxide dropwise, and control the temperature between 0-10°C. Continue to...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap