A kind of method utilizing bisphosphonic acid extractant to recover nickel from electroplating waste liquid

A technology for electroplating waste liquid and extraction agent, applied in the field of nickel recovery, can solve the problems of increasing the amount of post-extraction treatment, many times of extraction, and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) to contain Ni 2+ The electroplating waste solution is the water phase, and the Ni in the water phase 2+ The concentration is 0.7 g / L, and the pH of the aqueous phase is 4.

[0026] (2) Prepare 0.025mol / L HADMPPA and OADMPPA as the organic phase with diluent, dichloromethane, toluene, dichloroethane and chloroform respectively.

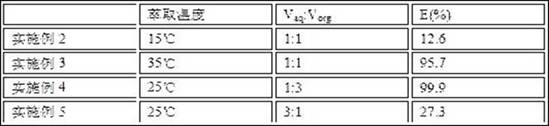

[0027] (3) Mix 5 mL each of the aqueous phase and the organic phase, extract for 10 min, and extract at 25 °C, and measure Ni in the raffinate 2+ See Table 1 for the concentration of the diluent on the extraction rate.

[0028] (4) Use 0.1mol / L dilute hydrochloric acid to carry out organic back-extraction after extraction. The back-extraction time is 20 minutes, the back-extraction temperature is 20°C, and the back-extraction rate is above 99%.

[0029] Table 1

[0030]

Embodiment 2

[0032] (1) to contain Ni 2+ The electroplating waste solution is the water phase, and the Ni in the water phase 2+ The concentration of the solution is 0.8 g / L, and the pH of the aqueous phase is 1.

[0033] (2) Using chloroform as the diluent, prepare 0.0565 mol / L HADMPPA as the organic phase.

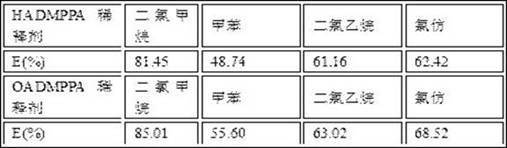

[0034] (3) 10 mL of the aqueous phase and organic phase were mixed, the extraction time was 10 min, the extraction temperature was 15 °C, and the Ni in the raffinate was determined 2+ The concentration and extraction rate are shown in Table 2.

[0035] (4) Use 0.1mol / L dilute hydrochloric acid to reverse the organic extraction after extraction. The stripping time is 30 min, the stripping temperature is 30°C, and the stripping rate is over 99%.

Embodiment 3

[0037] (1) to contain Ni 2+ The electroplating waste solution is the water phase, and the Ni in the water phase 2+ The concentration of the solution is 0.8 g / L, and the pH of the aqueous phase is 1.

[0038] (2) Using chloroform as the diluent, prepare 0.0565 mol / L HADMPPA as the organic phase.

[0039] (3) 10 mL of the aqueous phase and organic phase were mixed, the extraction time was 10 min, the extraction temperature was 35 °C, and the Ni in the raffinate was determined 2+ The concentration and extraction rate are shown in Table 2.

[0040] (4) Use 0.1mol / L dilute hydrochloric acid to reverse the organic extraction after extraction. The stripping time is 30 min, the stripping temperature is 30°C, and the stripping rate is over 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com