Waterproof construction method outside cross pipe gallery

A construction method and cross-pipe technology are applied in the field of waterproof construction outside the cross-pipe gallery, which can solve the problems of affecting the normal use of other pipe galleries, difficult to implement leak repair measures, and difficult to lay waterproof coils, so as to improve the waterproof effect and reduce the number of indwellings. , the effect of simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

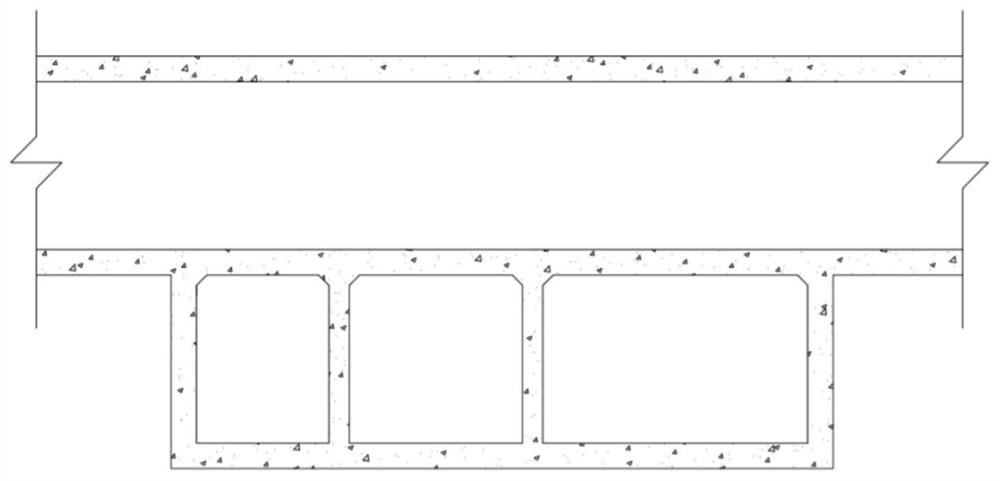

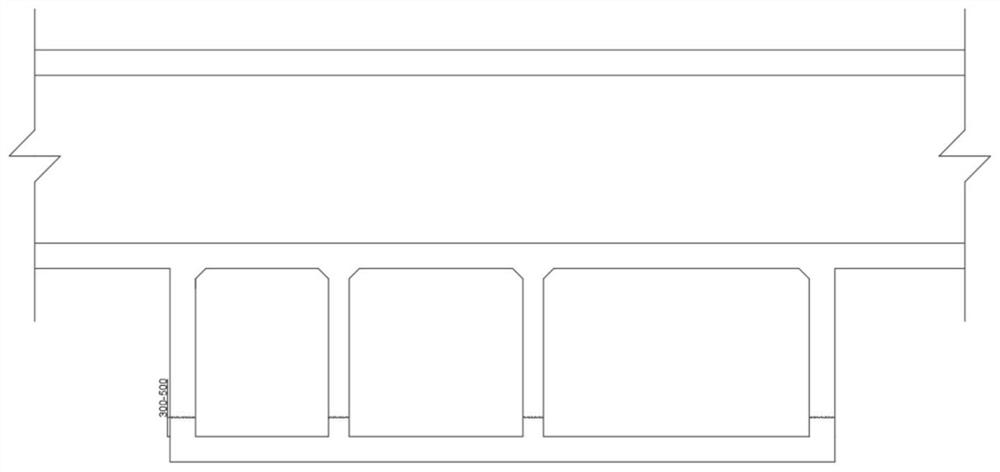

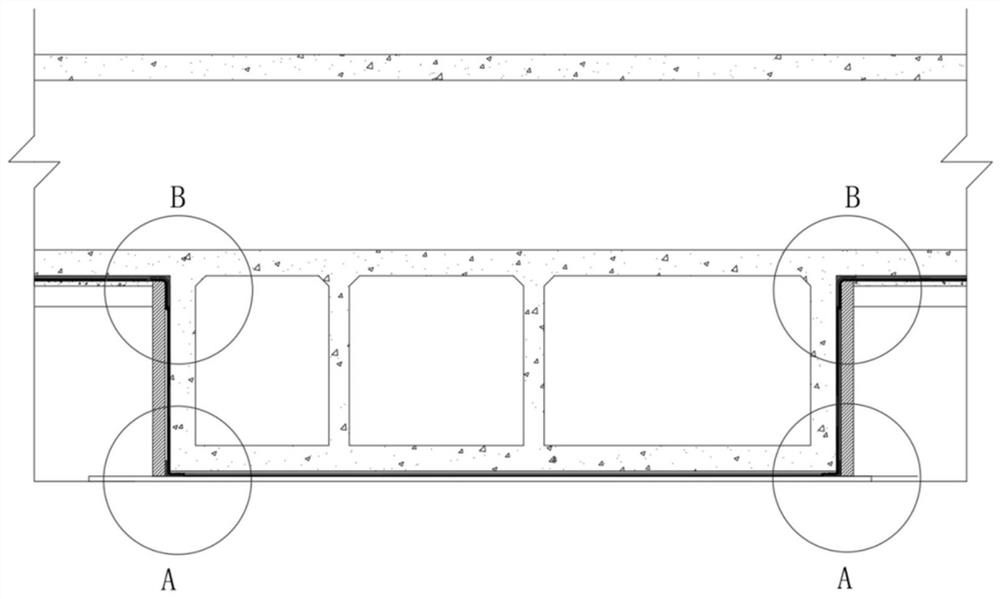

[0052] Such as Figure 1 to Figure 16 As shown, a waterproof construction method for the exterior of the crossing pipe gallery, the side walls of the main pipe gallery and the secondary pipe gallery are located at 300mm to 500mm above the top surface of the bottom plate, and the construction joint 8 includes the steps:

[0053] 1) Guide wall 5 and cushion construction;

[0054] 1.1) After the inspection of the foundation pit is qualified, a 100mm thick C20 concrete cushion 2 is laid on the bottom of the foundation pit. After the cushion reaches the design strength, the base of the cushion is treated;

[0055] 1.2) Build a 240mm thick guide wall 5 from both sides of the side wall 13 of the main corridor, and build the guide wall 5 from the bottom of the foundation pit to the bottom plate of the secondary pipe gallery 53mm below 15;

[0056] 1.3) The si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com