Anti-shaking quick pressurizing crane oil cylinder

A crane and anti-shake technology, applied in the field of hydraulic cylinders, can solve the problems of increased crane mechanical wear, cylinder loosening, telescopic rod jitter, etc., to reduce loosening and facilitate replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

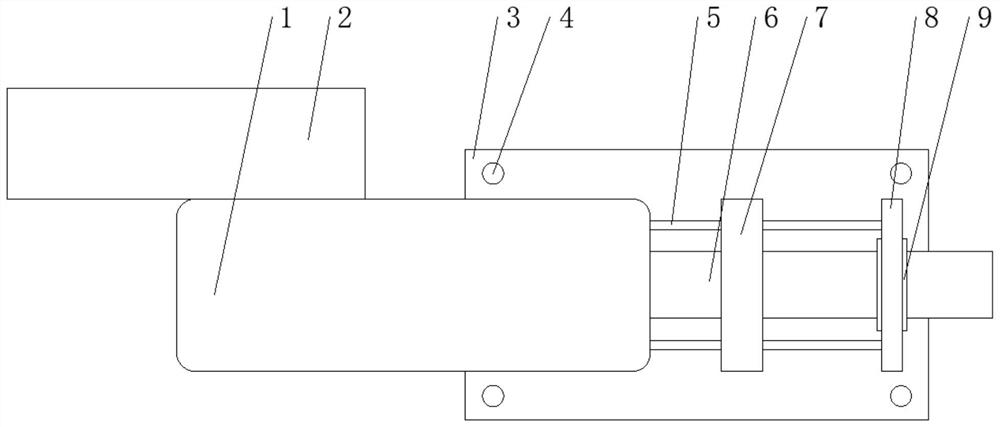

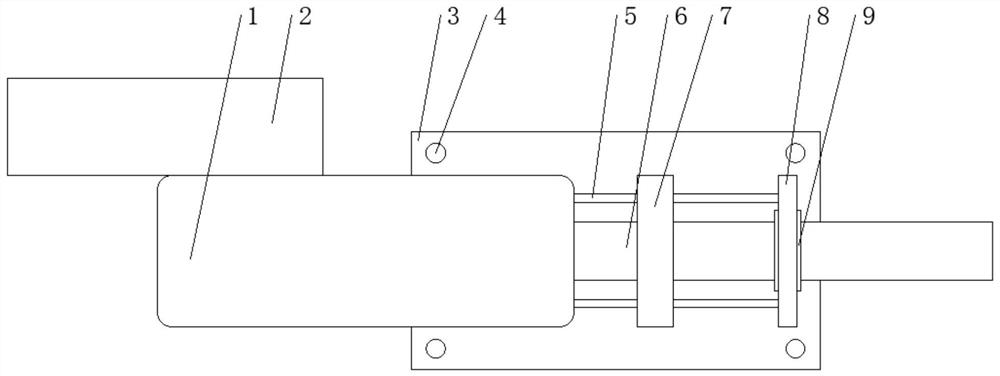

[0043] see Figure 1-2 , an anti-shake fast pressurized crane oil cylinder, including a hydraulic oil cylinder 1, a pressurized cylinder 2 is connected to one side of the hydraulic oil cylinder 1, a telescopic rod 6 is installed at the output end of the hydraulic oil cylinder 1, The output end is also fixedly installed with a connecting rod 5. The connecting rod 5 is connected with an ion wind ring 7 and a dust removal plate 8 in sequence. An electrostatic brush 9 is installed in the dust removal plate 8. On the plate 3, bolt holes 4 are drilled on the fixed plate 3, and the ion wind ring 7 and the dust removal plate 8 are fixedly installed on the fixed plate 3.

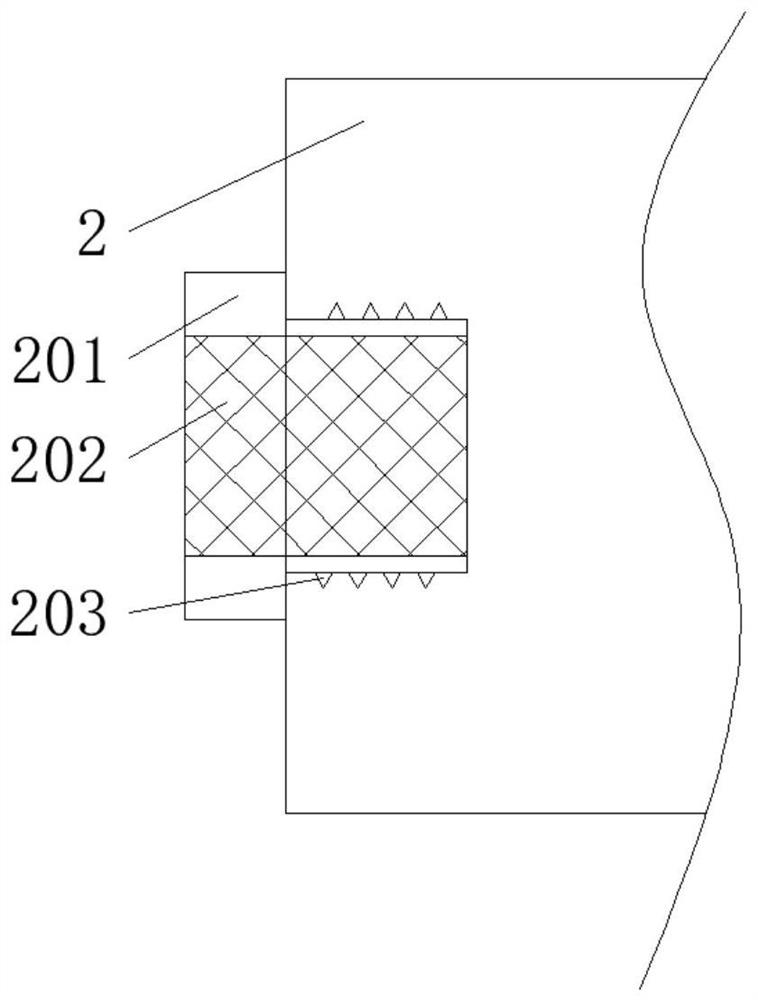

[0044] see Figure 3-4, the air inlet of the supercharged cylinder 2 is drilled with a connecting thread 203, the air inlet is connected with an air inlet plug 201 through the connecting thread 203, and an anti-skid pattern 204 is drilled on the outer surface of the air inlet plug 201, and in the middle of the air i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com