Vibration isolation device with high attitude precision

A high-profile, vibration-isolating technology, applied in the field of inertial equipment, can solve problems such as the inability to effectively reduce the vertical comprehensive stiffness, the difficulty in assembly implementation, and the inability to meet low-frequency vibration isolation, so as to improve lateral control capabilities, improve environmental adaptability, The effect of increasing the angular stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the drawings and specific examples. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

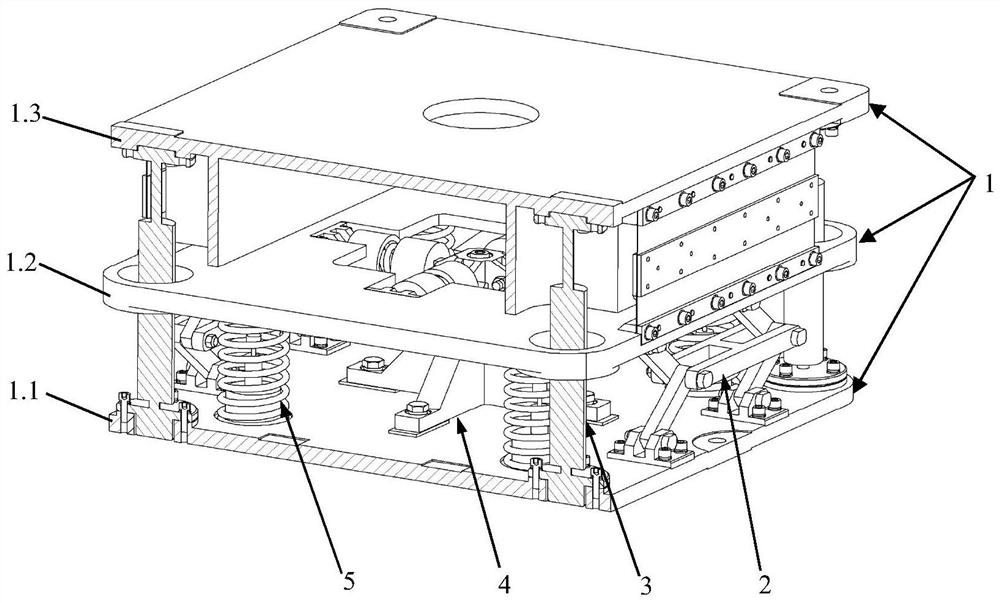

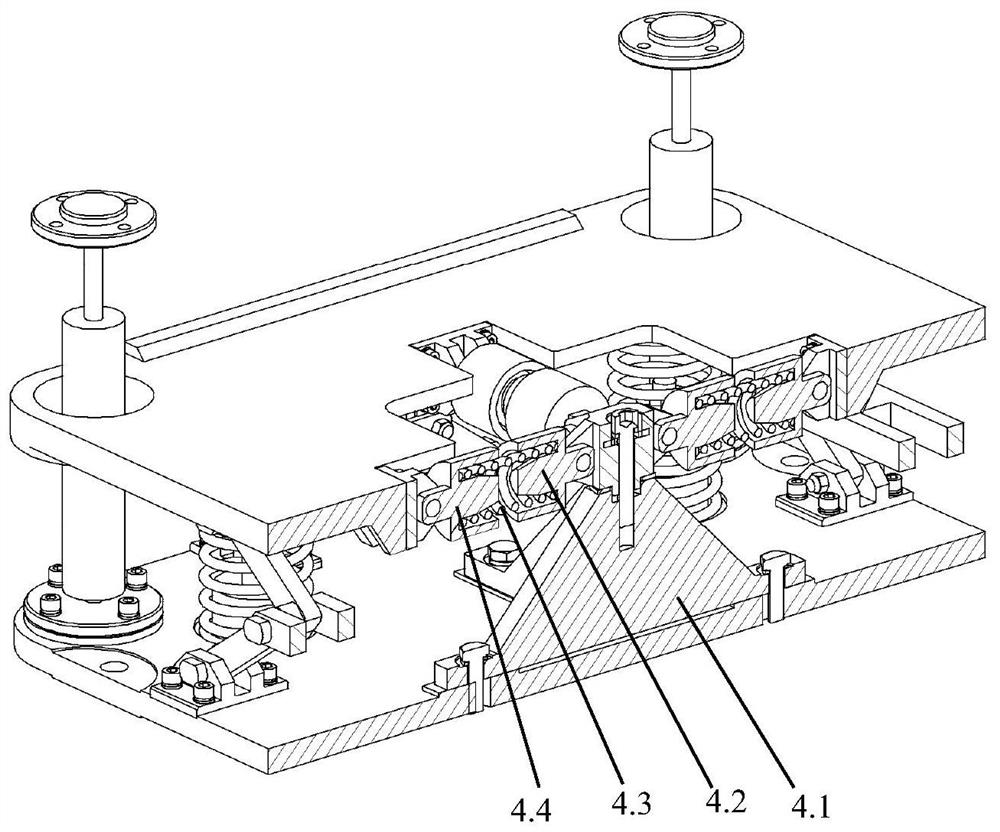

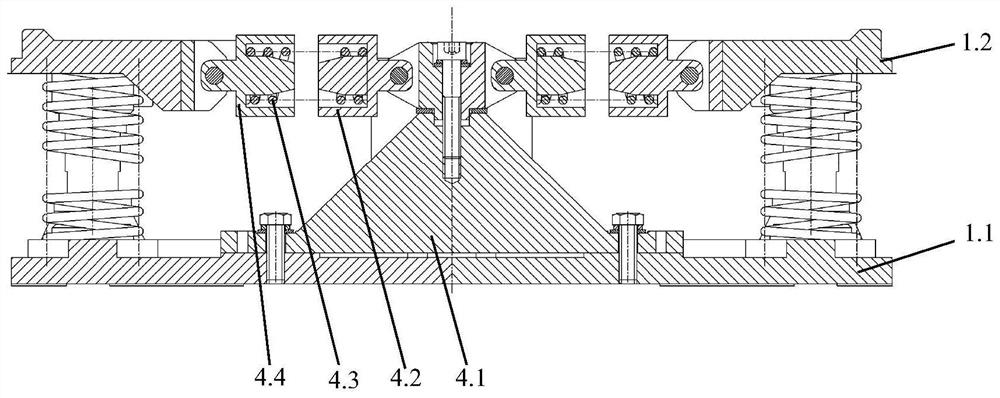

[0024] A vibration isolation device with high attitude accuracy, please refer to Figure 1-4 , is mainly composed of a vibration isolation support frame 1, a cylindrical helical compression spring 5, a damper 3, a negative stiffness mechanism 4 and a double parallelogram hinge linkage mechanism 2.

[0025] The vibration-isolation support frame is the base structure of the vibration-isolation device, which is composed of top plate 1.3, middle plate 1.2 and bottom plate 1.1 which are aligned up and down according to the spacing, and the upper end of the top plate is a mounting platform for the vibration-isolated object. The middle plate and the top plate are connected through the connecting piece in a manner that they are limite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com