Adjustable vertical pipe integral support and construction method thereof

An adjustable and integrated technology, applied in the direction of pipeline supports, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems that the process cannot meet the installation needs, the discreteness is difficult to control, and the installation labor cost is large, etc., to achieve pipeline and Easy maintenance and management, reasonable and standardized sorting, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

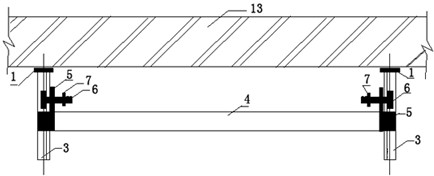

[0035] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described, but protection scope of the present invention is not limited thereto:

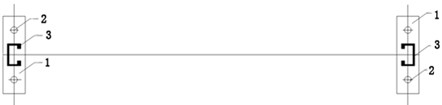

[0036] like figure 1 As shown, the outrigger 3 is a C-shaped steel structure, and its end is welded with the steel plate 1. Two DN12 screw holes 2 are drilled on the steel plate 1, and the inner expansion bolt passes through the screw hole 2 to fix the outrigger 3 on the wall 13 structure. The two ends of the cross bar 4 are respectively connected with the two legs 3 .

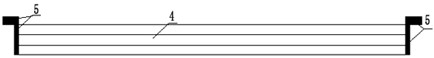

[0037] like figure 2 and image 3 As shown, the support leg 3 is connected to the wall by welding on the steel plate, and each of the two ends of the cross bar 4 is welded with an angle steel wing plate 5 parallel to each other and perpendicular to the cross bar 4, and a round hole is drilled on the angle steel wing plate 5 , the cross bar 4 passes through the angle steel wing plate 5, and the first T-shaped bolt 6 pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com