Lens design method and system and line lamp lens

A design method and lens technology, applied in the field of lighting, can solve problems such as narrow application range and inability to accurately distribute light, and achieve the effect of improving the divergence angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

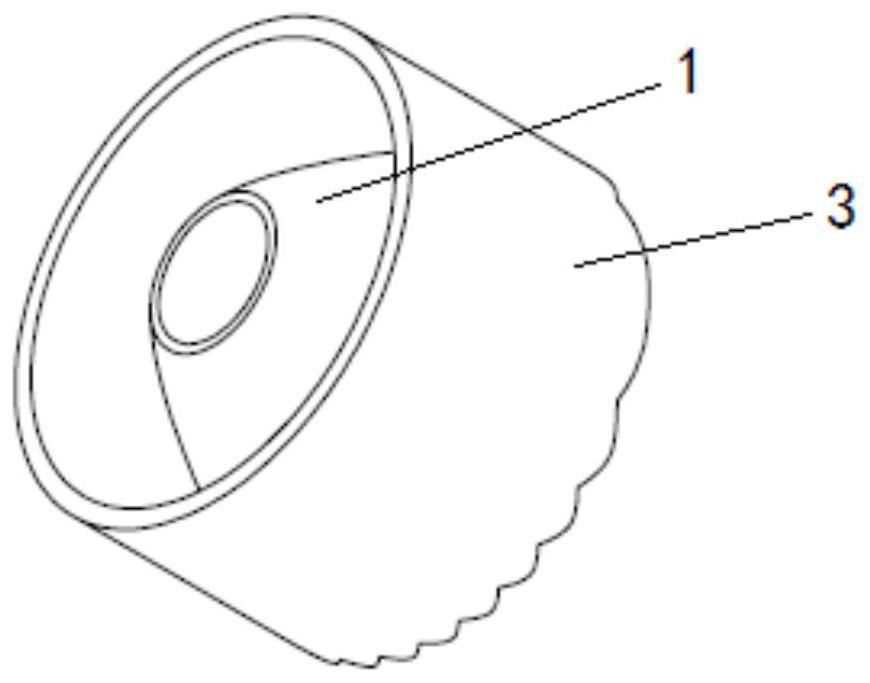

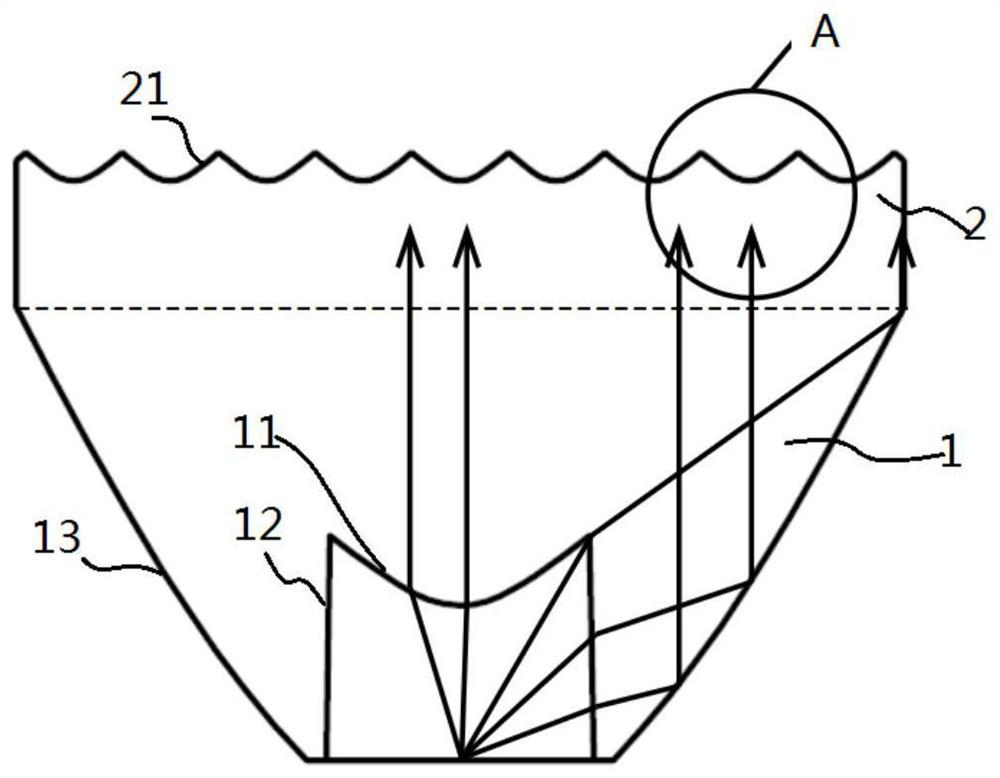

[0062] Embodiment 1, a kind of lens, such as Figures 1 to 4 As shown, the lens includes a lens body and a housing 3 with an inner cavity, wherein the lens body includes a collimated TIR structure 1 and an output layer 2, the collimated TIR structure 1 and the output layer 2 are located in the inner cavity, and the output layer 2 is located in Collimate the top of the TIR structure 1.

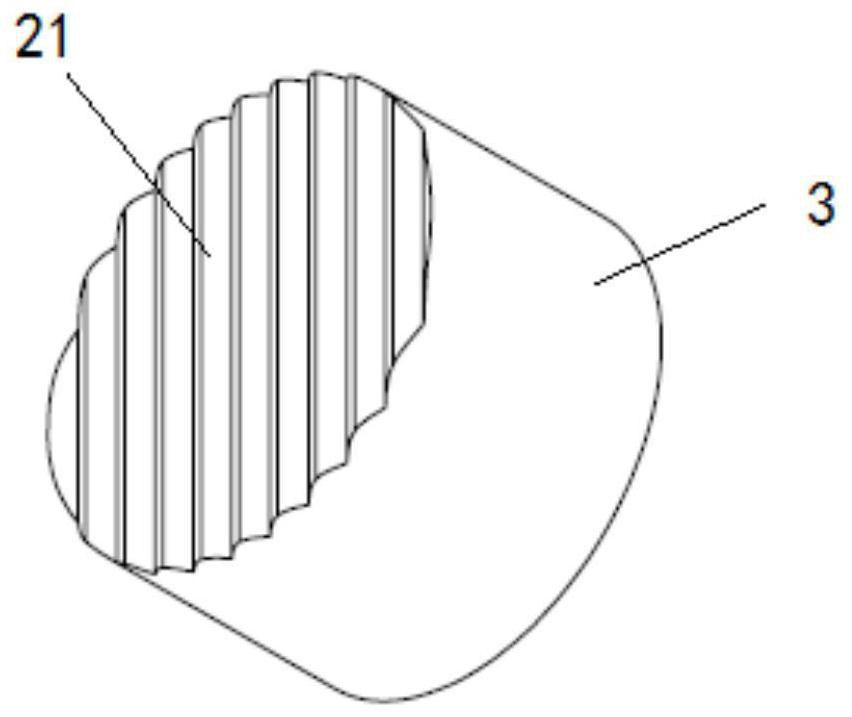

[0063] Such as image 3 As shown, the center of the light-emitting surface of the light source is located in the middle of the bottom of the lens, and the collimated TIR structure 1 is used to convert the light source light into collimated parallel light and emit it to the outgoing layer 2; the upper surface of the outgoing layer 2 is composed of several parallel The fringe curved surface 21 formed by the set fringes is the outgoing surface of the lens.

[0064] The striped curved surface 21 is a symmetrical structure, and the central point of the striped curved surface 21 is the highest poin...

Embodiment 2

[0153] Embodiment 2, when the initial refraction point is the vertex, after generating the corresponding striped surface 21 based on the section curve, a size optimization step is also included:

[0154] The height data also includes the thickness of the outgoing layer 2;

[0155] calculating and obtaining the height of the stripes based on the coordinates of each refraction point;

[0156] When the height of the stripes is smaller than the thickness of the emitting layer 2 , the height of the stripes is taken as the thickness of the emitting layer 2 .

[0157] When the applicable scene has relatively strict requirements on the size, the initial refraction point is used as the vertex, and the corresponding fringe surface 21 is generated with reference to the embodiment. At this time, the highest point of the fringe surface 21 is the preset lens height, and the lowest point of the fringe surface is not lower than the upper surface of the collimated TIR structure 1 .

[0158] ...

Embodiment 3

[0159] Embodiment 3. A lens design system, comprising:

[0160] The configuration module is used to configure the light distribution angle and initial size data, wherein the light distribution angle is greater than 0 and less than 90°, and the initial size data includes the height data of the lens and the width data of the stripes;

[0161] A design module, which includes a configuration unit, a coordinate calculation unit and a curve generation unit;

[0162] The configuration unit is configured to configure the number of refraction points on the section curve, generate incident light data corresponding to each refraction point based on the width data, and generate outgoing light corresponding to each refraction point based on the light distribution angle data;

[0163] The coordinate calculation unit is configured to use the apex or the lowest point of the stripe as an initial refraction point, determine the coordinates of the initial refraction point based on the height da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com