Energy-saving bamboo product drying equipment

A technology for drying equipment and bamboo products, which is applied in drying, drying machines, lighting and heating equipment, etc. It can solve the problems of small contact area, long time, prolonging the drying time of bamboo steamer, etc., and achieve faster drying speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Please refer to Figure 1-Figure 5 , the specific embodiments of the present invention are as follows:

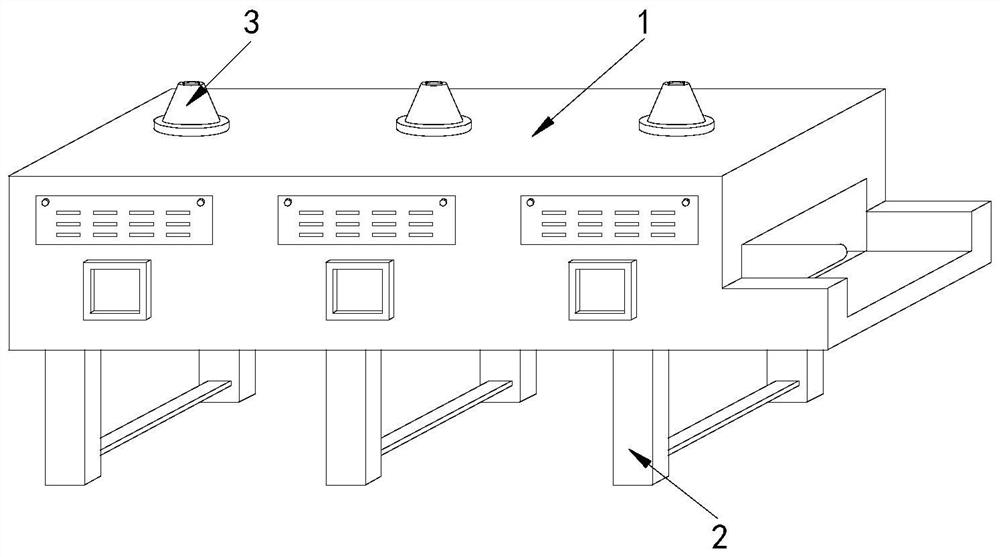

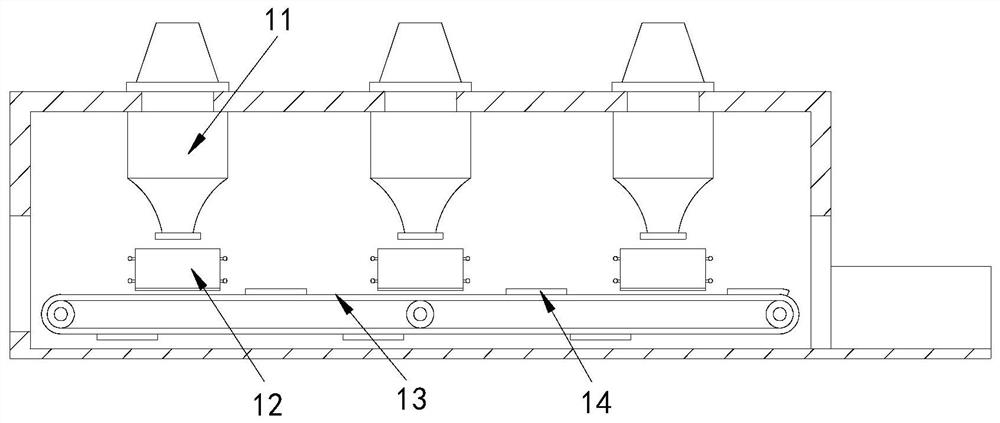

[0027] Its structure includes a main body 1, a supporting foot 2, and an air inlet 3. The bottom end of the main body 1 is provided with a supporting foot 2. There are three air inlets 3 arranged horizontally on the top of the main body 1. The main body 1 It includes a dryer 11, a side plate 12, a conveyor belt 13, and a placement seat 14. There are three dryers 11, which are respectively connected directly below the air inlet 3. There are six side plates 12, with Two sets are arranged at both ends below the dryer 11 , the conveyor belt 13 is installed horizontally in the middle of the main body 1 , and there are six placement seats 14 arranged laterally on the end surface of the conveyor belt 13 .

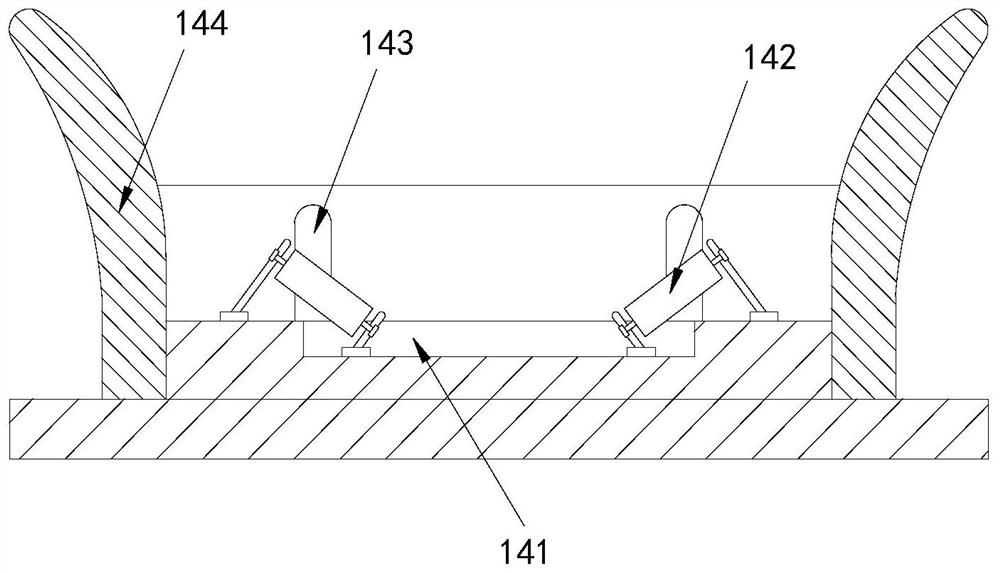

[0028] The placement seat 14 includes a water collection tank 141, a placement roller 142, an auxiliary plate 143, and a wind deflector 144. The water collec...

Embodiment 2

[0032] Example 2: Please refer to Figure 6-Figure 8 , the specific embodiments of the present invention are as follows:

[0033] The air deflector 144 includes an air inlet b1, a circulation groove b2, an air outlet b3, and an air guiding device b4. The air inlet b1 is arranged on the top of the air deflector 144, and the circulation groove b2 is located below the air inlet b1. , the air outlet b3 is provided with four, and is vertically arranged at the side end of the circulation groove b2, the air guiding device b4 is installed at the rear end of the air inlet b1, and the width of the air inlet b1 is from the inner end to the outside The end gradually expands, which is beneficial to guide a large amount of hot air to the inside of the circulation groove b2.

[0034] The air guide device b4 includes a guide plate b41, a block b42, a movable groove b43, and a return spring b44. The guide plate b41 is engaged on the top of the air guide plate 144, and the block b42 is embedde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com