Engine piston connecting rod detection device

A technology of piston connecting rod and detecting device, which is applied to mechanical measuring devices, measuring devices, and mechanical devices, etc., can solve the problems of inaccurate, vertical, and incapable of guaranteeing vernier calipers and pistons in the detection method, so as to achieve better use effects and improved performance. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

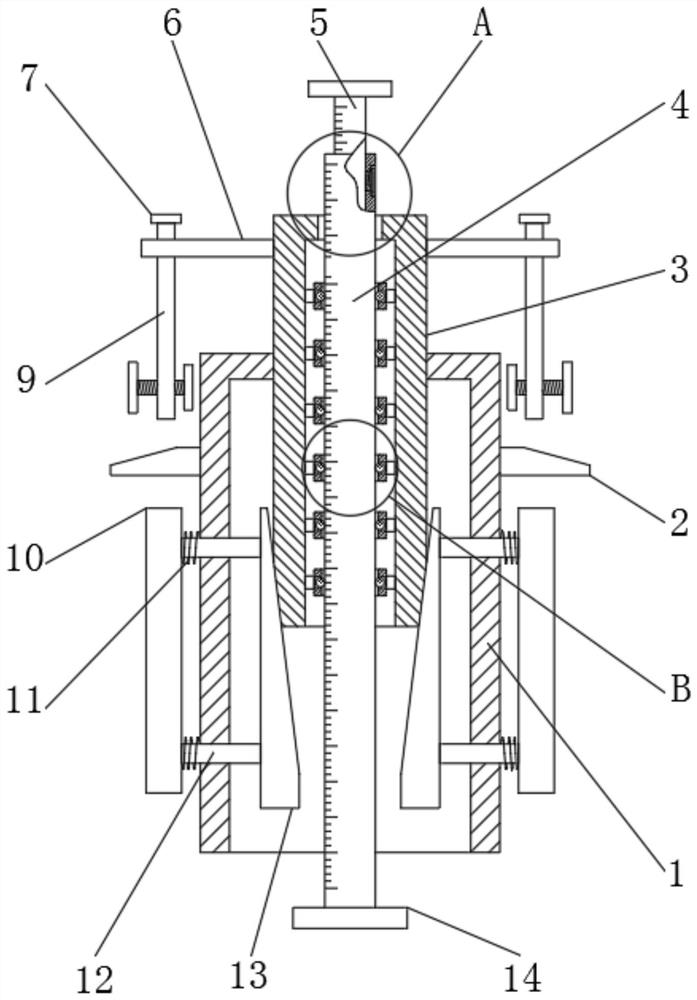

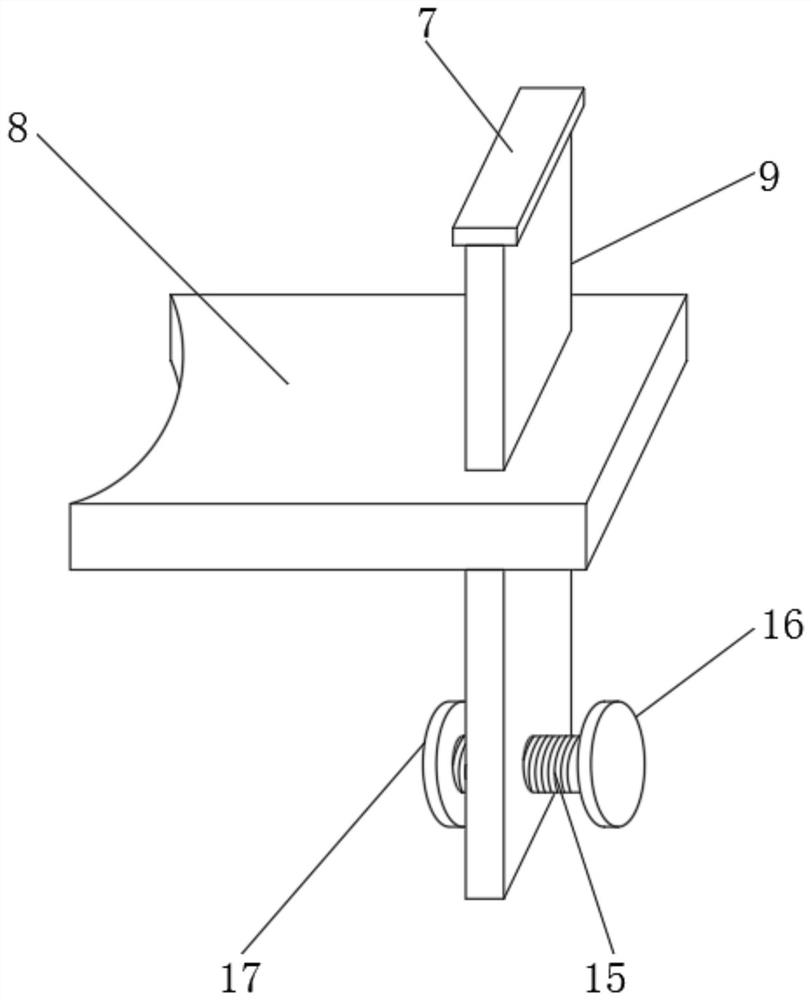

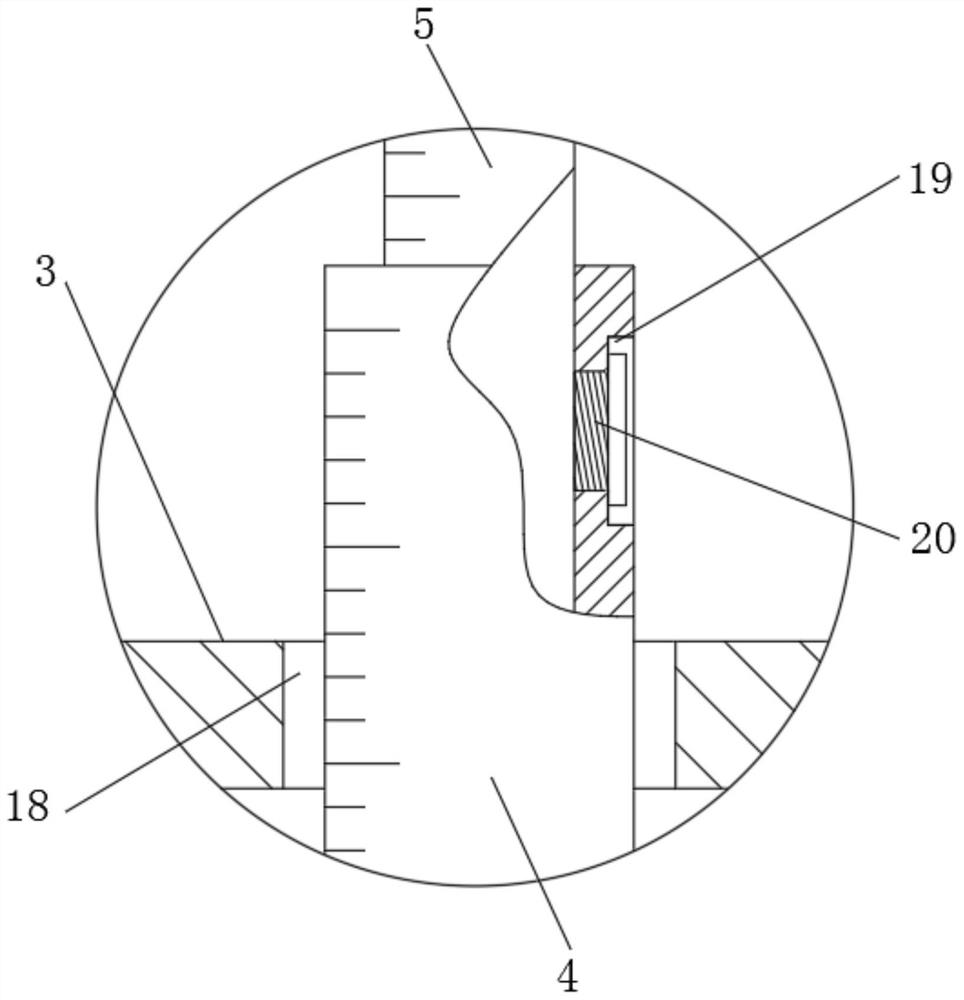

[0028] refer to Figure 1-4 , an engine piston connecting rod detection device, including a fixed cylinder 1, the top outer wall of the fixed cylinder 1 has a limit opening, and the inner wall of the limit opening is slidably connected with a movable cylinder 3, and the outer walls of the fixed cylinder 1 are all provided with sliding holes , and the inner wall of the sliding hole is slidably connected with a movable rod 12, one end of the movable rod 12 is fixedly connected with a movable block 13, and the other end of the movable rod 12 is fixedly connected with an arc-shaped plate 10, and one side of the movable block 13 is provided with an oblique Chamfering, the outer wall of the movable cylinder 3 has a circular chamfer, and the outer wall of the circular chamfer matches the outer wall of the oblique chamfer, the inside of the movable cylinder 3 is provided with a measuring mechanism, and the inside of the movable cylinder 3 is also provided with a As an auxiliary mechan...

Embodiment 2

[0036] refer to Figure 5 , a detection device for an engine piston and connecting rod. Compared with Embodiment 1, this embodiment further includes a rubber pad 25 bonded to the outer wall of the arc-shaped plate 10 .

[0037] Working principle: when in use, the rubber pad 25 on the arc-shaped plate 10 can increase the friction with the inner wall of the spark plug installation hole, making the fixing more stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com