Dental restoration tooth preparation axial surface polymerization degree inspector

A technology for oral prosthesis and preparation, applied in the direction of angle/taper measurement, etc., can solve the problems of inconvenient angle adjustment, difficult to put in and in place, easy to loosen and fall off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

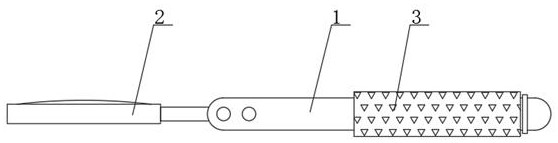

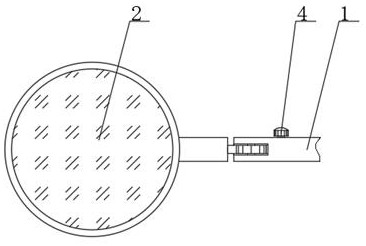

[0021] see Figure 1-5 , the present invention provides a technical solution: an axial-surface polymerization degree checker for dental prosthetic tooth preparation, including a connecting rod 1, the top of the connecting rod 1 is connected to a dental mirror 2 through a rotating shaft, and the oral mirror 2 is provided with an anti- The atomization mechanism, the connection between the connecting rod 1 and the oral mirror 2 is provided with an angle adjustment mechanism, the interior of the oral mirror 2 is provided with a battery storage chamber 7, the battery storage chamber 7 is located at the bottom of the anti-atomization mechanism, and the bottom of the oral mirror 2 The end is connected with a storage cavity cover 9 through rotation, and the storage cavity cover 9 is a T-shaped structure, and a rubber gasket is provided at the connection between the dental mirror 2 and the storage cavity cover 9.

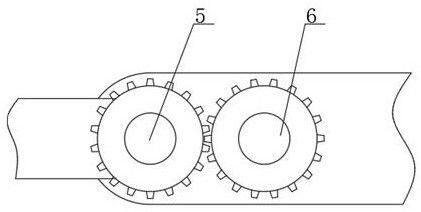

[0022] In this embodiment, an anti-fogging mechanism is installed insid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com