Tension experiment mechanism for aviation tray mooring ring

A tensile test and mooring technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, instruments, measuring devices, etc., can solve the problem that it is difficult to judge the quality of the mooring ring, and achieve simple structure and ensure accuracy. the effect of reducing the influence of more variables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0026] This embodiment provides a tension test mechanism for the mooring ring of the aviation pallet, which has a simple structure, is convenient to adjust, can carry out tension tests of different sizes, and can withstand relatively large tension.

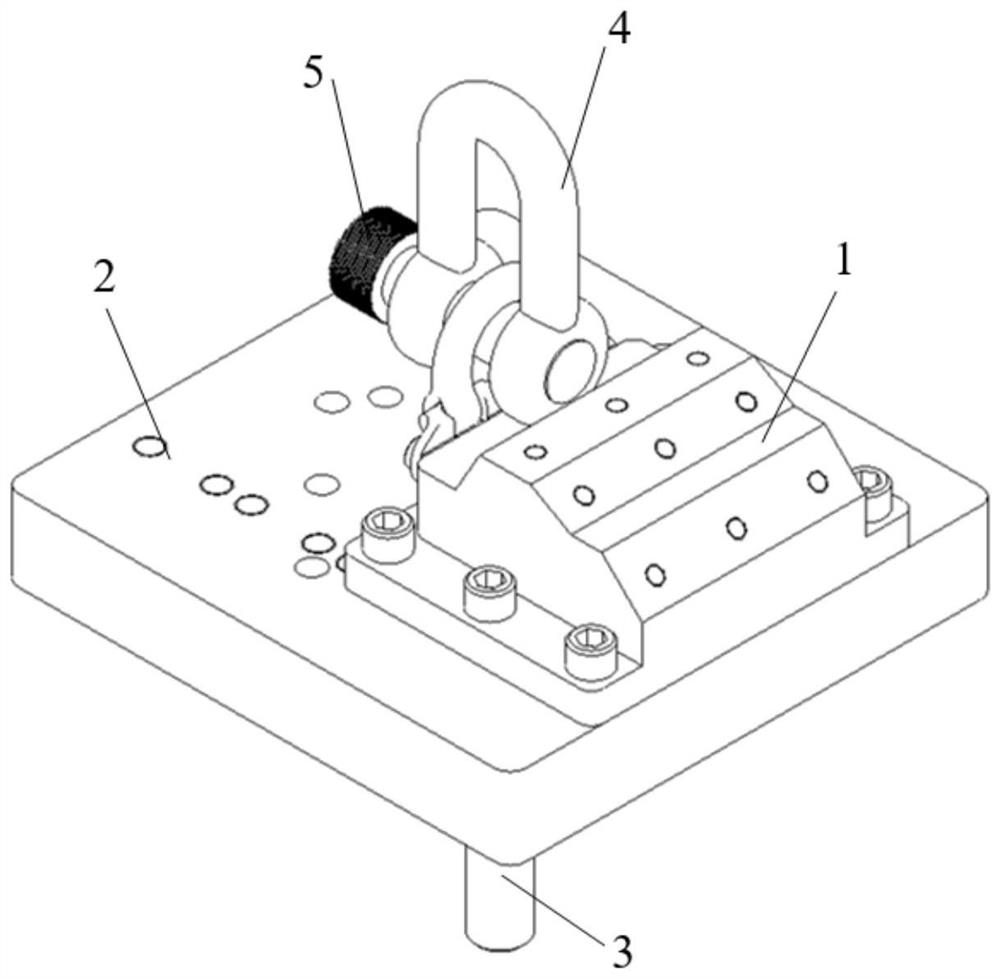

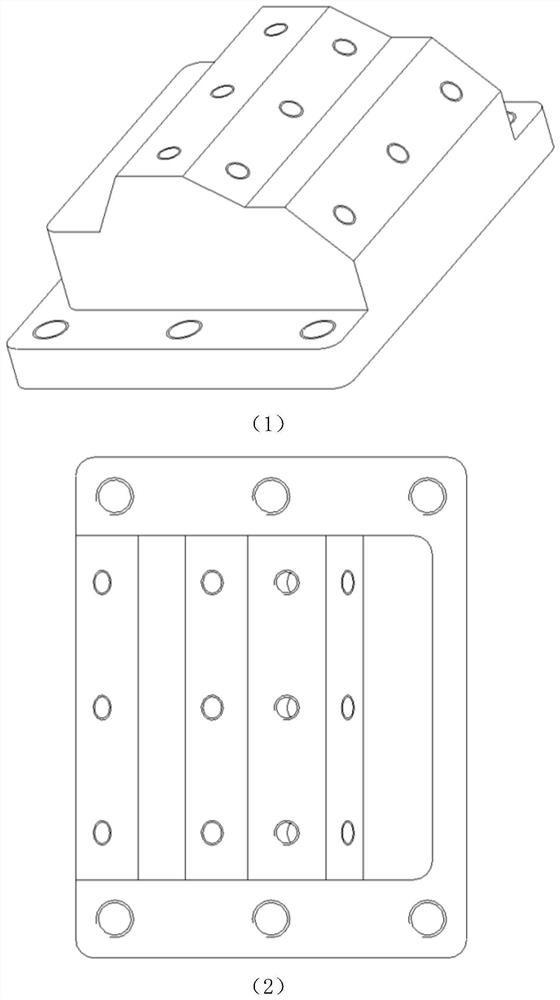

[0027] Such as figure 1 As shown, the tensile test mechanism includes: a mooring ring fixing block 1 , an installation platform 2 , a clamping rod 3 , a mooring ring tension sleeve 4 and a threaded pin 5 .

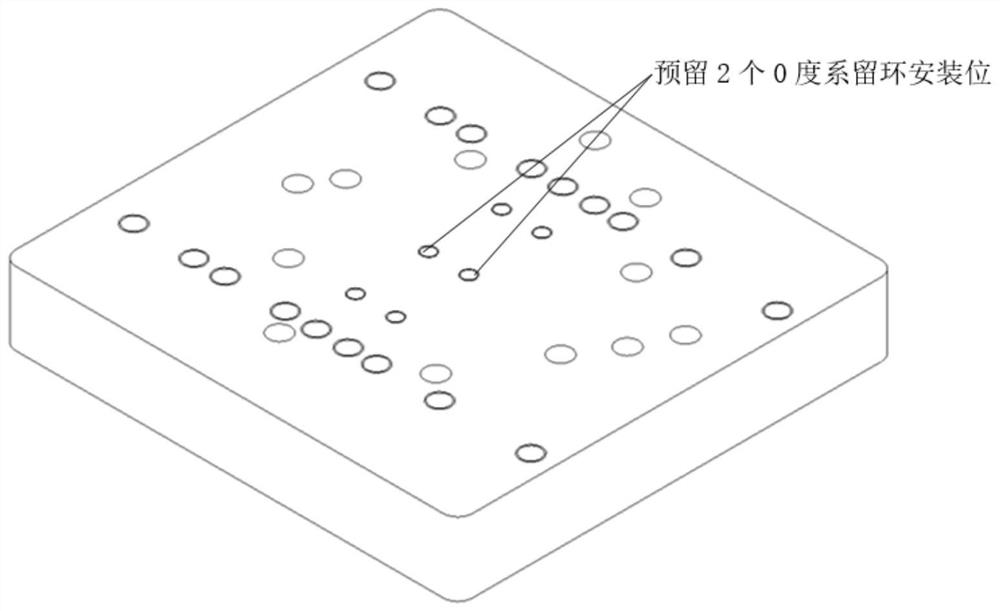

[0028] The connection relationship of the tensile test mechanism is as follows: figure 2 As shown, the installation platform 2 is provided with a plurality of installation holes for installing the mooring ring fixing block 1, so as to meet the installation of the mooring ring 6 at different angles; At the set position on the upper surface of the platform 2, the clamping rod 3 is welded at the set positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com