Method for testing UV ratio of positive photoresist

A positive photoresist and ratio technology, which is used in the preparation of test samples and the measurement of color/spectral characteristics, which can solve the problems of cumbersome process and waste of diluent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

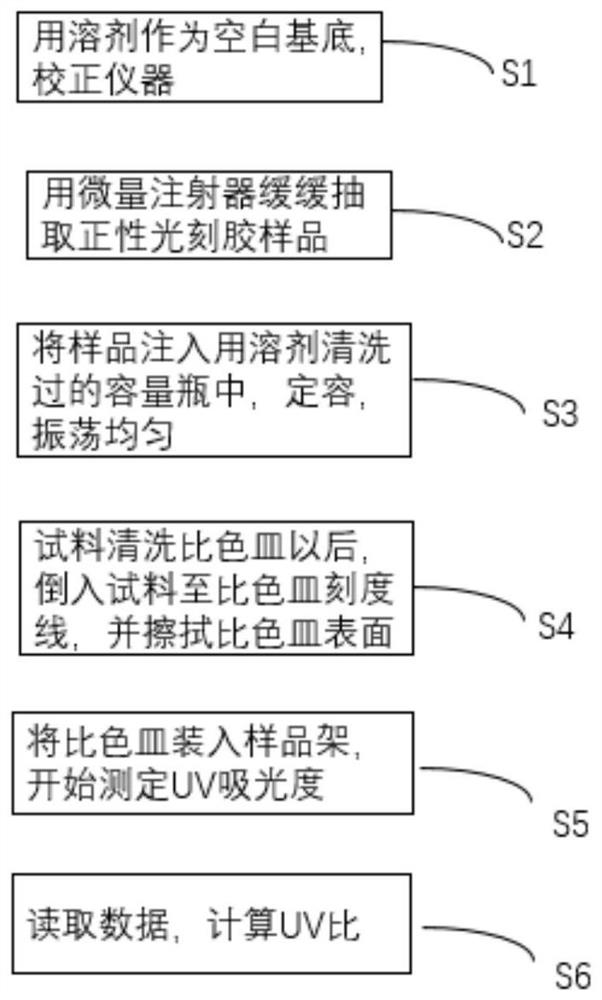

Image

Examples

Embodiment 1

[0025] Embodiment one (3.2cP positive photoresist):

[0026] First, use propylene glycol methyl ether acetate solution as a blank substrate, read the absorbance values at 280nm and 350nm, and the values are all between ±0.0005, and then the sample can be tested. Take a 34uL sample with a micro syringe, inject it into a 50mL volumetric flask cleaned with propylene glycol methyl ether acetate, set the volume to the mark, oscillate fully, and dissolve. Clean the cuvette with the sample for 5 times, pour the sample to the scale line of the cuvette, wipe the surface of the cuvette clean with a dust-free paper, put the cuvette into the sample holder, start the test of the sample, read 280nm and 350nm The Abs values at are 1.813 and 0.483 respectively, and the calculated UV ratio is 3.754;

Embodiment 2

[0027] Embodiment two (3.5cP positive photoresist):

[0028] Take 34uL of positive photoresist sample with a micro-syringe, other steps are the same as in Example 1, the obtained diluted solution is measured, and the Abs values at 280nm and 350nm are read, which are 1.815 and 0.483 respectively, and the calculated UV ratio is 3.757;

Embodiment 3

[0029] Embodiment three (3.6cP positive photoresist):

[0030] Take 34uL of positive photoresist sample with a micro-syringe, other steps are the same as in Example 1, the obtained diluted solution is measured, and the Abs values at 280nm and 350nm are read, which are 1.819 and 0.484 respectively, and the calculated UV ratio is 3.758;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com