Turnable cable duct inspection device

A technology for inspection devices and cable ducts, which is applied to cable installation devices, cable installation in underground pipelines, cable installation, etc. It can solve problems such as the lack of automatic turning of the device, unstable operation of the pipeline, and limited application scenarios. Strong traffic capacity, enhanced applicability, and increased application scenarios

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

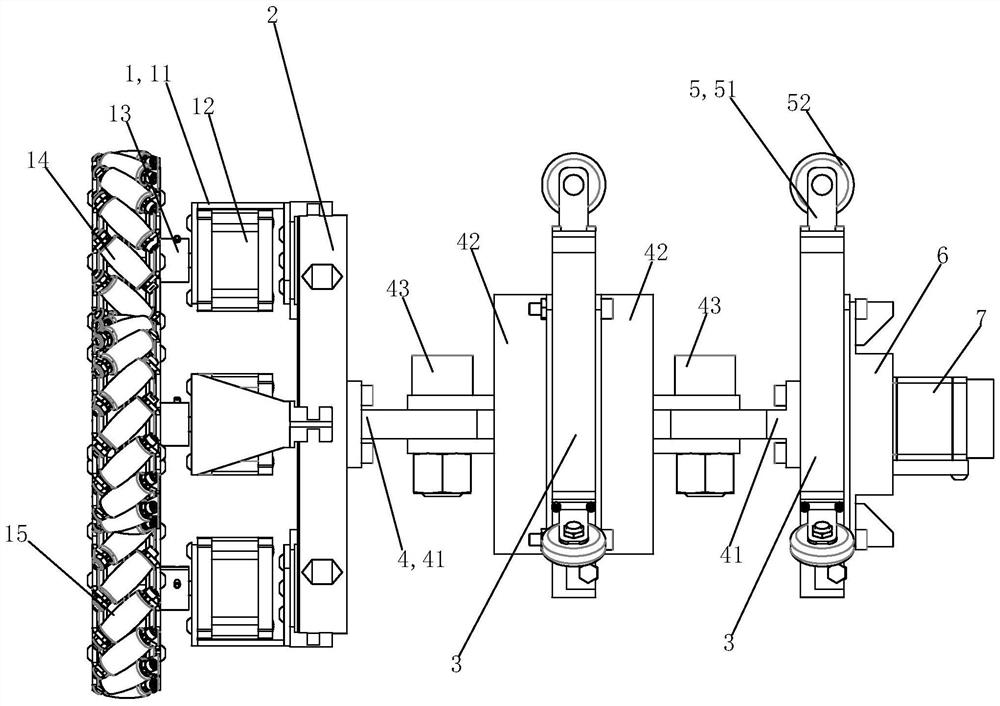

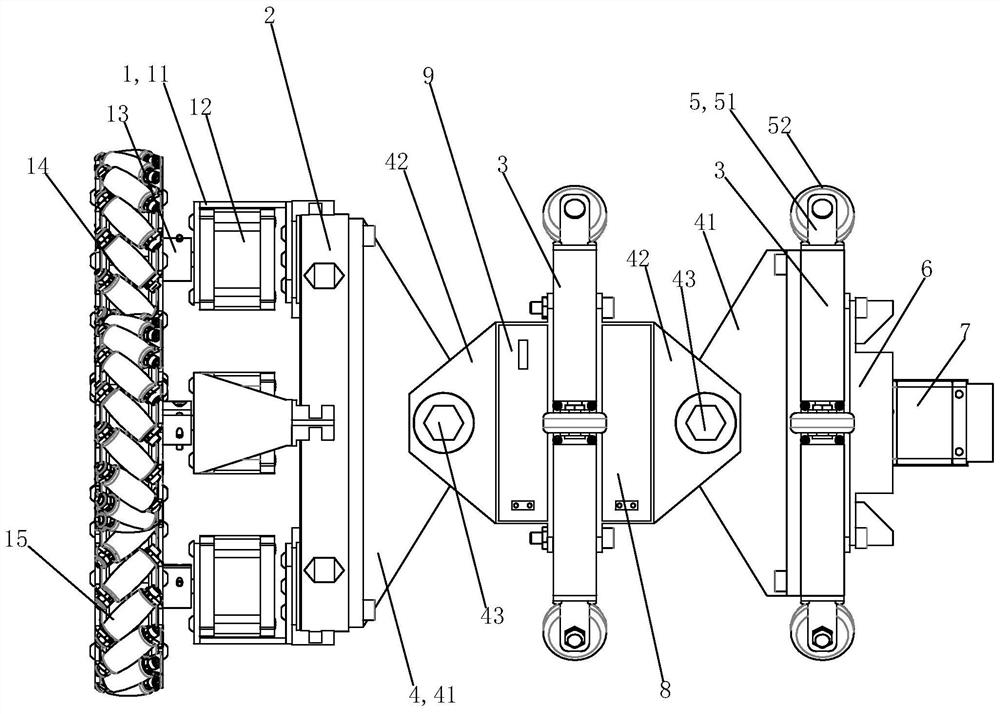

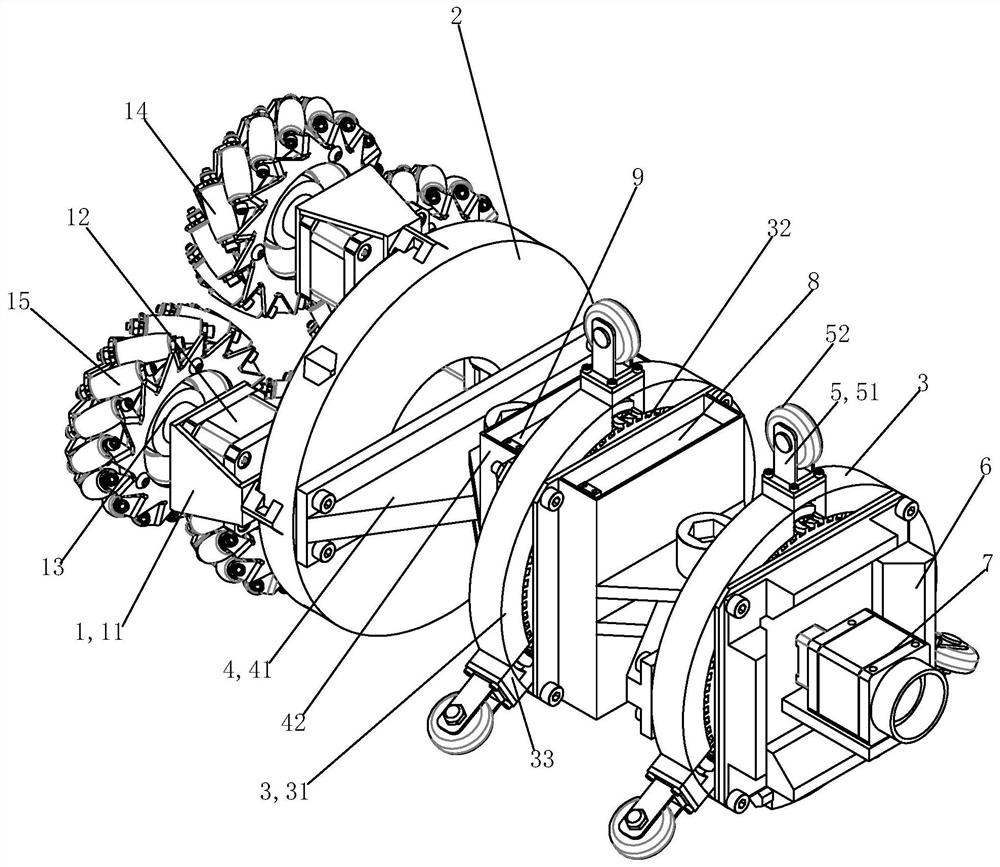

[0034] See Figure 1 to Figure 4 , the turnable cable duct inspection device of the present embodiment is mainly composed of a drive assembly 1, a four-jaw chuck 2, a three-jaw chuck 3, an installation connection assembly 4, a walking wheel assembly 5, an LED light 6, a camera 7, a battery The box 8 and the controller 9 are composed.

[0035] The driving assembly 1 includes 4 motor brackets 11 , 4 motors 12 , 4 connecting flanges 13 , 2 cis-Nam wheels 14 and 2 inverse-Nam wheels 15 . The motor 12 is a commercially available DC motor, and the Shun Nam wheel 14 and the reverse Nam wheel 15 are all commercially available parts. One motor 12 is fixedly installed in each motor bracket 11; each motor is connected to a connecting flange 13 for transmission; 2 Shun Nam wheels 14 and 2 reverse Nam wheels 15 are respectively connected to 1 Lan 13 is fixedly connected, and 2 Shun Nam wheels 14 and 2 reverse Nam wheels 15 are arranged oppositely. The circumferential force generated by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com