Filter for removing viruses

A filter and virus technology, applied in the field of virus-removing filters, can solve the problems of inconvenient processing and complex structure of the membrane support plate, and achieve the effects of simple assembly, increased virus retention, and easy manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

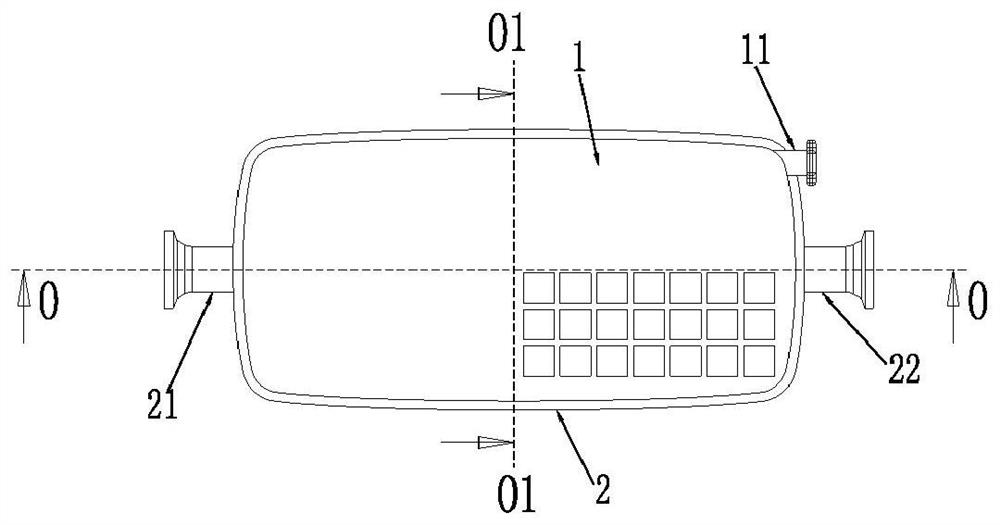

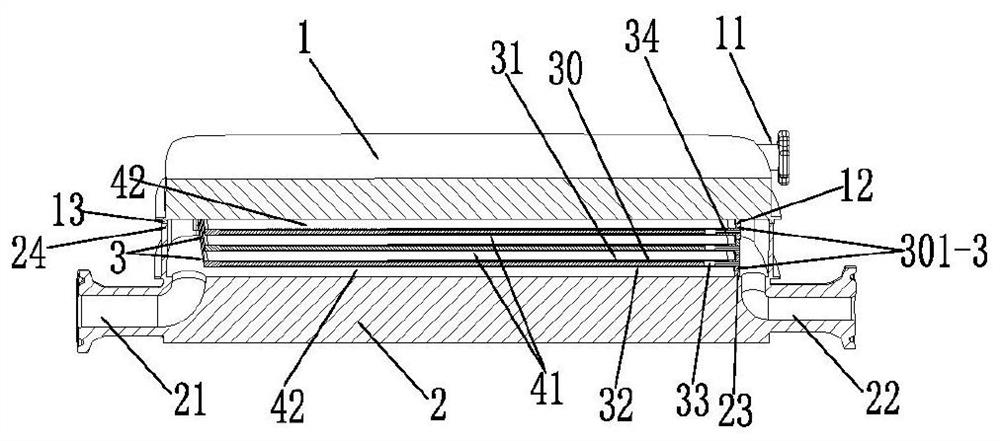

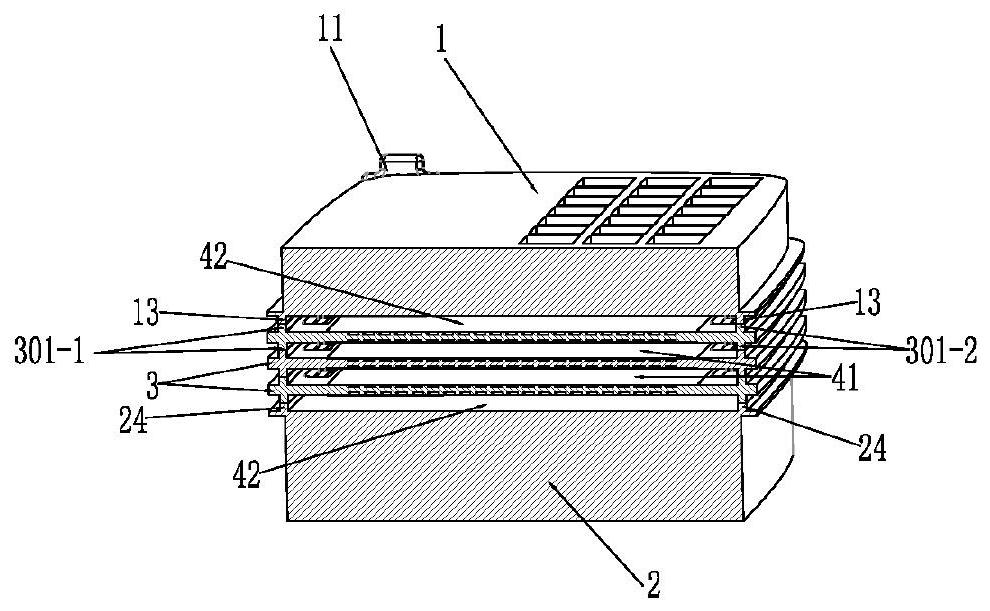

[0078] Such as Figure 1-Figure 6 The filter for removing viruses of the first structure shown includes a liquid inlet 21, a liquid outlet 22, an exhaust port 11, a top cover 1, a bottom cover 2 and a seal fixed on the top cover 1 and the bottom cover. The filter plate 3 between 2, the exhaust port 11 is located in the top cover 1. In this embodiment, both the liquid inlet 21 and the liquid outlet 22 are located in the bottom cover 2 . Of course, the liquid inlet 21 and the liquid outlet 22 can also be separately provided on the top cover 1 and the bottom cover 2 .

[0079] Such as figure 2 with image 3 As shown, the filter plate 3 includes a membrane support plate 30 and a first filter membrane 31 and a second filter membrane 32 that are respectively sealed and fixed on the first surface and the second surface of the membrane support plate 30, the first filter membrane 31 and the second filter membrane The membranes 32 each include multiple layers, and the outer surface...

Embodiment 2

[0110] Such as Figure 7-13 The virus-removing filter of the second structure shown is substantially the same structure as the filter provided in Example 1, and will not be repeated here. However, in this filter, the structure of the membrane support plate 30 is slightly different, which will be described in detail below.

[0111] Such as Figure 11-Figure 13 As shown, the main structure of the membrane support plate 30 is the same as the main structure of the membrane support plate 30 in Embodiment 1, the difference is: in this embodiment 2, the membrane support plate 30 has a first end close to the liquid inlet 21 and Near the second end of the liquid outlet 22, the first end of the membrane support plate 30 has a third through hole 30C communicated with the liquid inlet 21, and the second end of the membrane support plate 30 has a fourth through hole communicated with the liquid outlet 22. The through hole 30D, which is located at the outlet 304B end of the confluence cha...

Embodiment 3

[0119] In this embodiment, the main structure of the filter is the same as that of the filter provided in Embodiment 2. However, in the third embodiment, the structure of the membrane support plate 30 is different from that of the membrane support plate 30 in the second embodiment.

[0120] Such as Figure 18-Figure 20 As shown, only the first end of the membrane support plate 30 near the liquid inlet 21 is formed with a third through hole 30C penetrating through its entire thickness, and the fourth through hole 30D is not provided at its second end near the liquid outlet 22. . Of course, a fourth through hole 30D may also be provided.

[0121] The first surface of the film support plate 30 has a first through hole 30A, and the second surface has a second through hole 30B, and the first through hole 30A, the second through hole 30B and the outlet are formed between the first surface and the second surface. The confluence channel 304 communicated with the liquid port 22 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com