Waterproof roll storage and collection device and working method thereof

A technology of waterproof coiled material and working method, applied in sorting and other directions, can solve the problems of surface contamination, damage, and manpower requirement of the coiled material, and achieve the effect of easy arrangement and storage, good storage effect, and avoiding uneven arrangement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

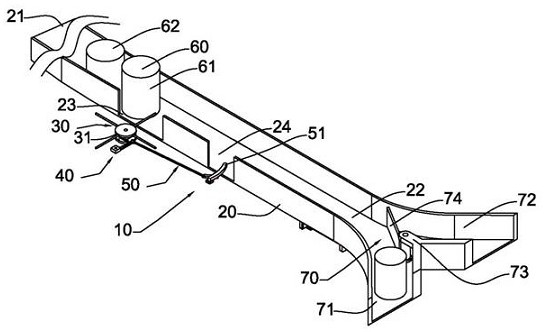

[0050] Such as Figure 1 to Figure 3 As shown, the storage and collection device for waterproof rolls in this embodiment includes a roll forming device and a transfer device 10 , and the transfer device 10 includes an oblique storage channel 20 , a rotating member 30 , a stopper 40 and a driving member 50 .

[0051] The inclined accommodation channel 20 has an inlet end 21 and an outlet end 22 , and the position of the inlet end 21 is higher than that of the outlet end 22 . The inlet port 21 is used for the entry of the waterproof winding roller 60 (entry from a relatively high position). The outlet port 22 is used for discharging the waterproof roll 60 , and the oblique accommodation channel 20 also has a first opening 23 and a second opening 24 .

[0052] Such as Figure 4 and Figure 5 As shown, the rotating member 30 has a rotating body 31 and a toggle lever 32, four toggle levers 33, 34, 35, 36 are evenly arranged around the rotating body 31, and there are multiple eve...

no. 2 example

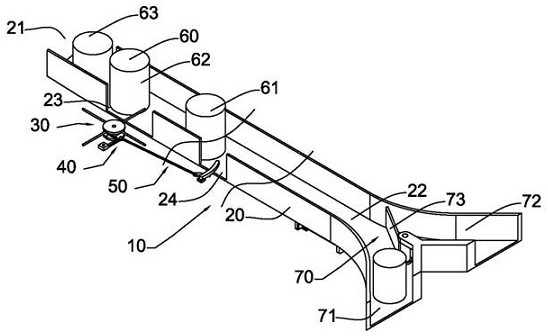

[0065] A separation assembly 70 is provided at the outlet end 22 , and the separation assembly 70 includes a first separation channel 71 , a second separation channel 72 and a separation plate body 73 . The first separation passage 71 communicates with the oblique accommodation passage 20 . The second separation channel 72 communicates with the inclined accommodation channel 20, and there is a partition plate 74 between the second separation channel 72 and the first separation channel 71; the partition plate 74 is hinged at the end of the separation plate body 73;

[0066] The working method includes the following steps:

[0067] When the waterproof coiled material is removed from the outlet port 22, it can be removed from the first separation channel 71 or the second separation channel 72;

[0068] In the S11 step, the partition plate 74 is used to cover the second separation channel 72, and the waterproof coiled material can only be removed from the first separation channel...

no. 3 example

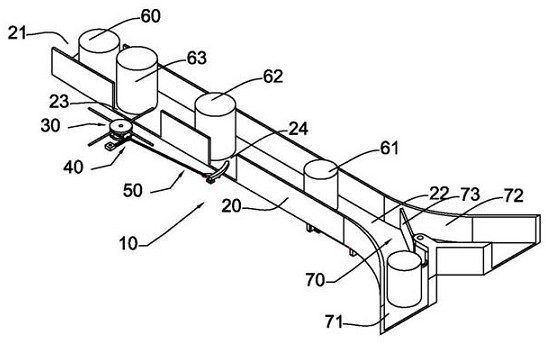

[0070] Such as Figure 7 As shown, on the bottom wall 25 of the oblique accommodation channel 20, a cylinder 26, a driving body 27, and an annular connecting body 28 are sequentially arranged. The annular connecting body 28 is fixed on the separation plate body 73 through a rotating shaft 29, and the cylinder 26 is fixed by the first The plate 35 is fixed on the second fixed plate 36, the driving body 27 has a U-shaped structure, and the open end of the U-shaped structure and the annular connecting body 28 are hinged through the connecting shaft 37;

[0071] The method comprises the following steps:

[0072] The telescoping rod of the cylinder 26 drives the driving body 27 to move, thereby making the annular connecting body 28 move, and then making the rotating shaft 29 drive the separating plate body 73 to articulate, thereby selectively closing the first separating channel 71 or the second separating channel 72 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com