5G chip manufacturing process

A manufacturing process and chip technology, applied in the field of 5G chip manufacturing process, can solve the problems of high manufacturing cost, unable to guarantee the quality of the wafer, and reduce the efficiency, and achieve the effect of ensuring quality, preventing breakage and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable those in the technical field to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

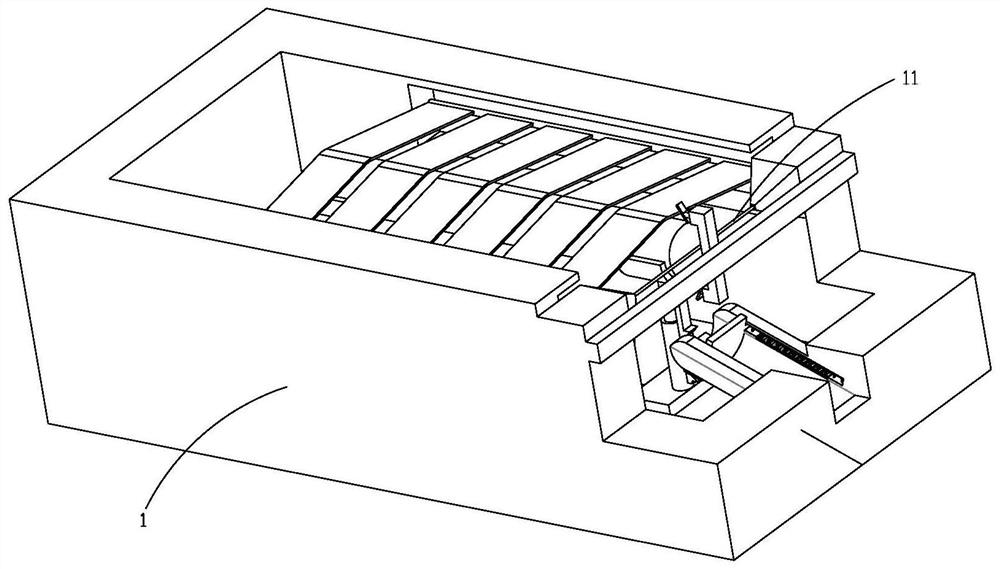

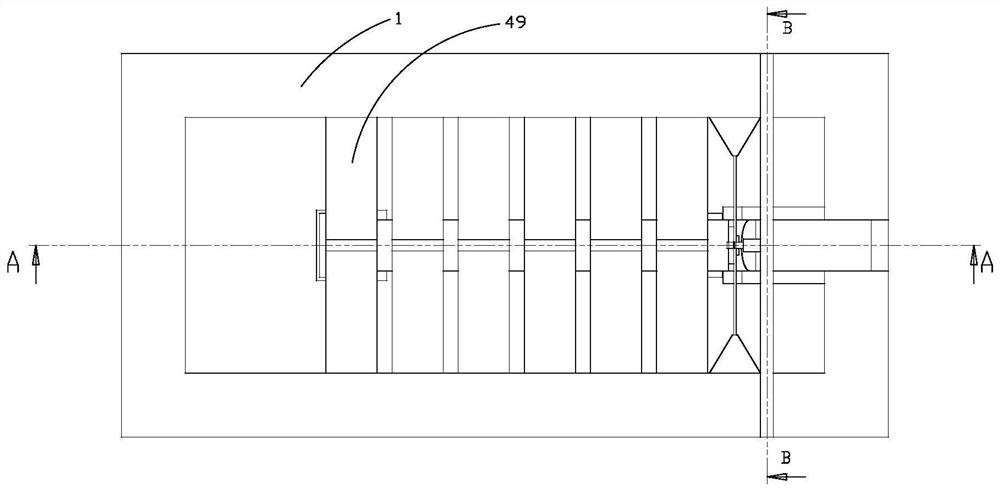

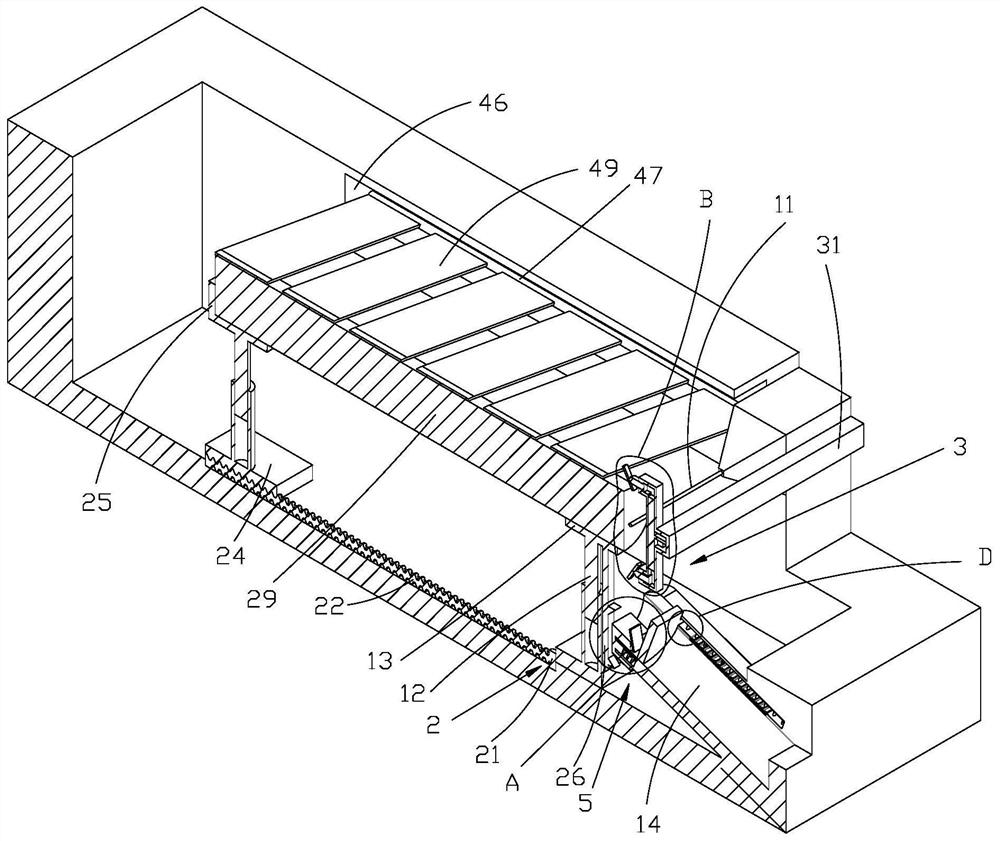

[0025] A 5G chip manufacturing process, the manufacturing process includes the following steps: Step 1: raw material preparation: melting the raw material for silicon wafer manufacturing into silicon melt; step 2: raw material molding: waiting for the temperature of the silicon melt in step 1 After stabilization, the seed crystal is inserted into the silicon melt, and then the seed crystal is lifted up to form a silicon wafer ingot 29; Step 3: outer diameter grinding: the silicon wafer ingot 29 made in step 2 is placed Carry out outer diameter grinding in the outer diameter grinder; Step 4: Slicing: Cut the silicon wafer crystal ingot 29 after the outer diameter grinding i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap