Automobile steering transmission mechanism

A technology for steering transmission and automobiles, which is applied to steering mechanisms, power steering mechanisms, fluid steering mechanisms, etc. It can solve the problems of single steering mechanism and insufficient stability, and achieve the effects of improving grip, enhancing stability, and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

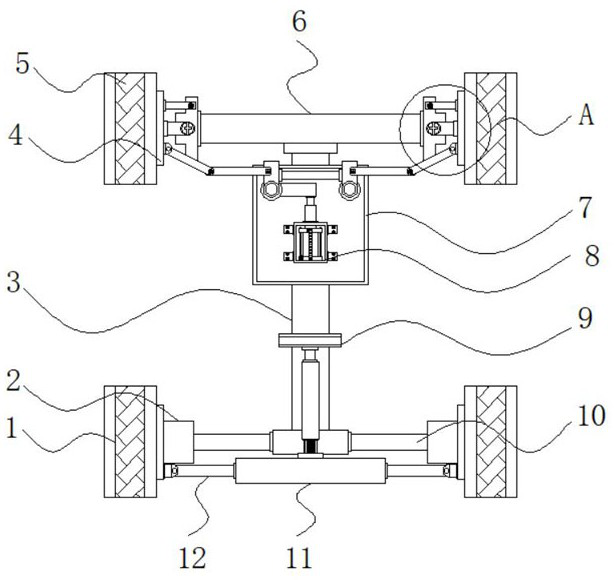

[0035] Example 1: See Figure 1-6 , an automobile steering transmission mechanism, comprising a front wheel 1 and a rear wheel 5, a transverse shaft 10 is fixedly connected between one side of the front wheel 1, and anti-wear structures 14 are arranged on both sides of the transverse shaft 10, and one side of the front wheel 1 A shock-absorbing structure 2 is provided, and the top end of the horizontal shaft 10 is fixedly connected with a connecting rod 3, and the top end of the connecting rod 3 is fixedly connected with a connecting rod 6, and the two sides of the connecting rod 6 are fixedly connected with two groups of rear wheels 5 and front wheels 1 One side of the rear wheel 5 is fixedly connected with a fixed shaft 4, one end of the connecting rod 3 is fixedly connected with a base plate 7, and the bottom end of the base plate 7 is fixedly connected with a drive mechanism 8, and the outer parts of the front wheel 1 and the rear wheel 5 are fixedly connected respectively....

Embodiment 2

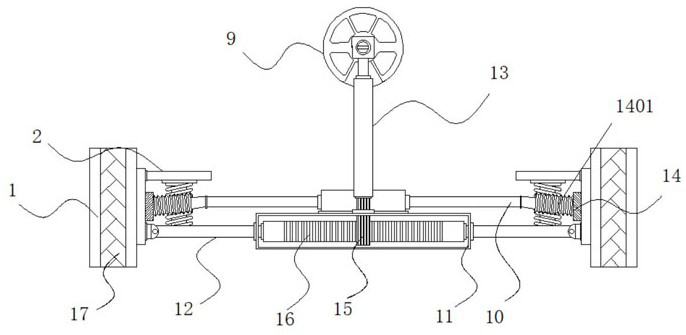

[0040] Embodiment 2: the outsides of the front wheel 1 and the rear wheel 5 are respectively fixedly connected with anti-slip sleeves 17;

[0041] Specifically, such as figure 1 As shown, the anti-skid cover 17 is arranged on the outside of the front wheel 1 and the rear wheel 5. When the car is on a slippery road or a steep road, it can increase the friction between the car and the road, and improve the grip of the car on the road. In this way, when the steering mechanism drives the automobile to turn, the automobile can be protected against slipping and overturning.

Embodiment 3

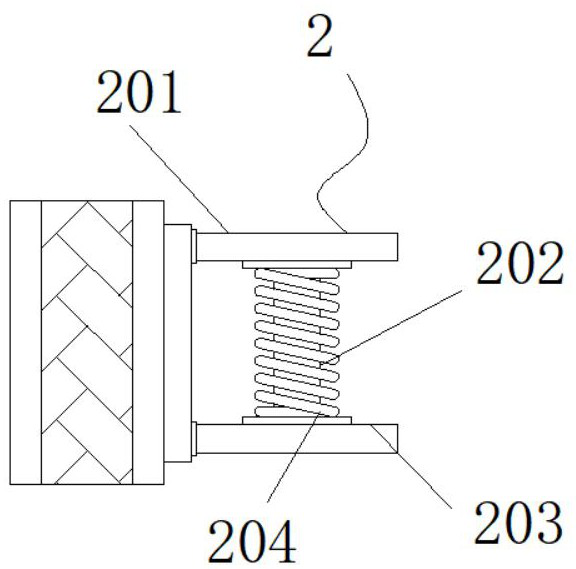

[0042] Embodiment 3: The damping structure 2 is composed of a first buffer plate 201, a strut 202, a spring 203 and a second buffer plate 204. The first buffer plate 201 is fixedly connected to the bottom of the front wheel 1 side, and the front wheel 1 side is The bottom of the bottom is fixedly connected with a second buffer plate 204, and a strut 202 is fixedly connected between the second buffer plate 204 and the first buffer plate 201, and a spring 203 is arranged on the outside of the strut 202;

[0043] The width of the outside of the strut 202 is smaller than the width of the inside of the spring 203, and the strut 202 is embedded in the inside of the spring 203;

[0044] Specifically, such as figure 1 and image 3 As shown, the first buffer plate 201 and the second buffer plate 204 on one side of the front wheel 1 fix the middle strut 202 and spring 203 on one side of the front wheel 1. When the road is smooth, the strut 202 and the spring 203 can protect the automo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com