Intelligent garbage can

A garbage can and intelligent technology, applied in the field of garbage cans, can solve the problems of convenience for those who cannot throw garbage and recycle garbage, single function of intelligent garbage cans, and low practicality of garbage cans, so as to achieve small diffraction phenomenon and high frequency , good direction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

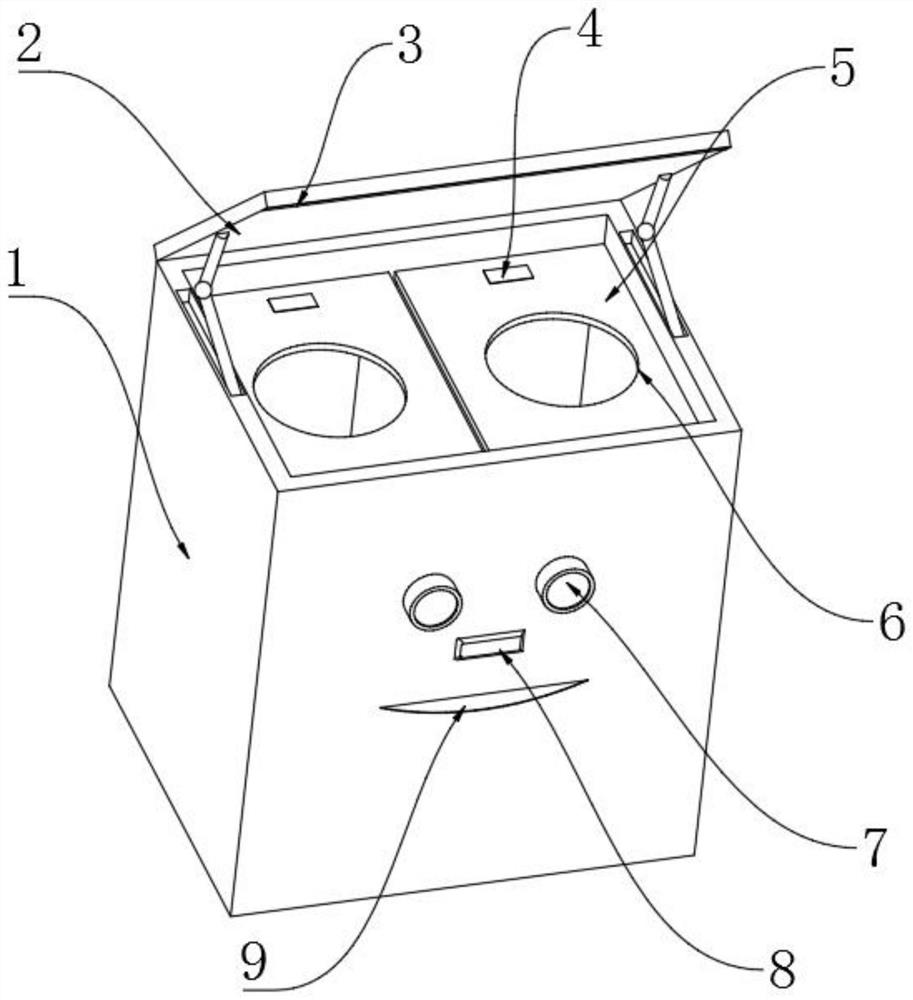

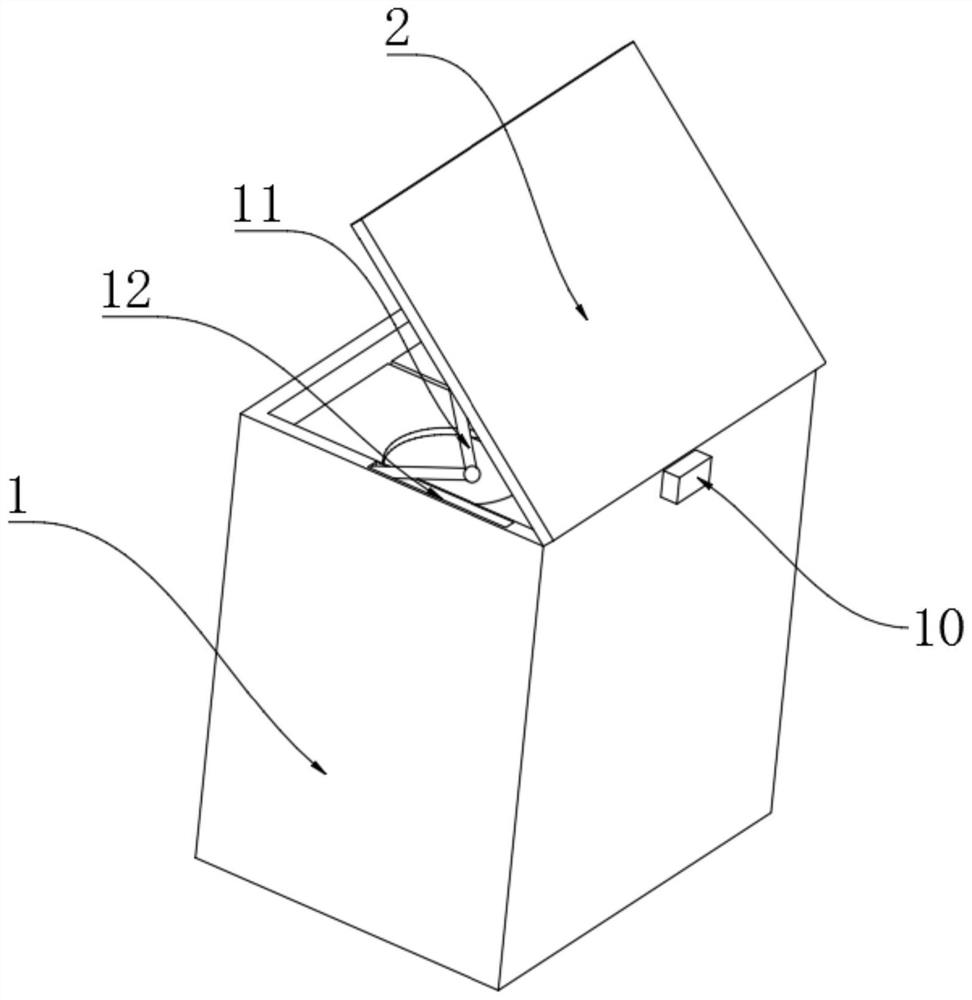

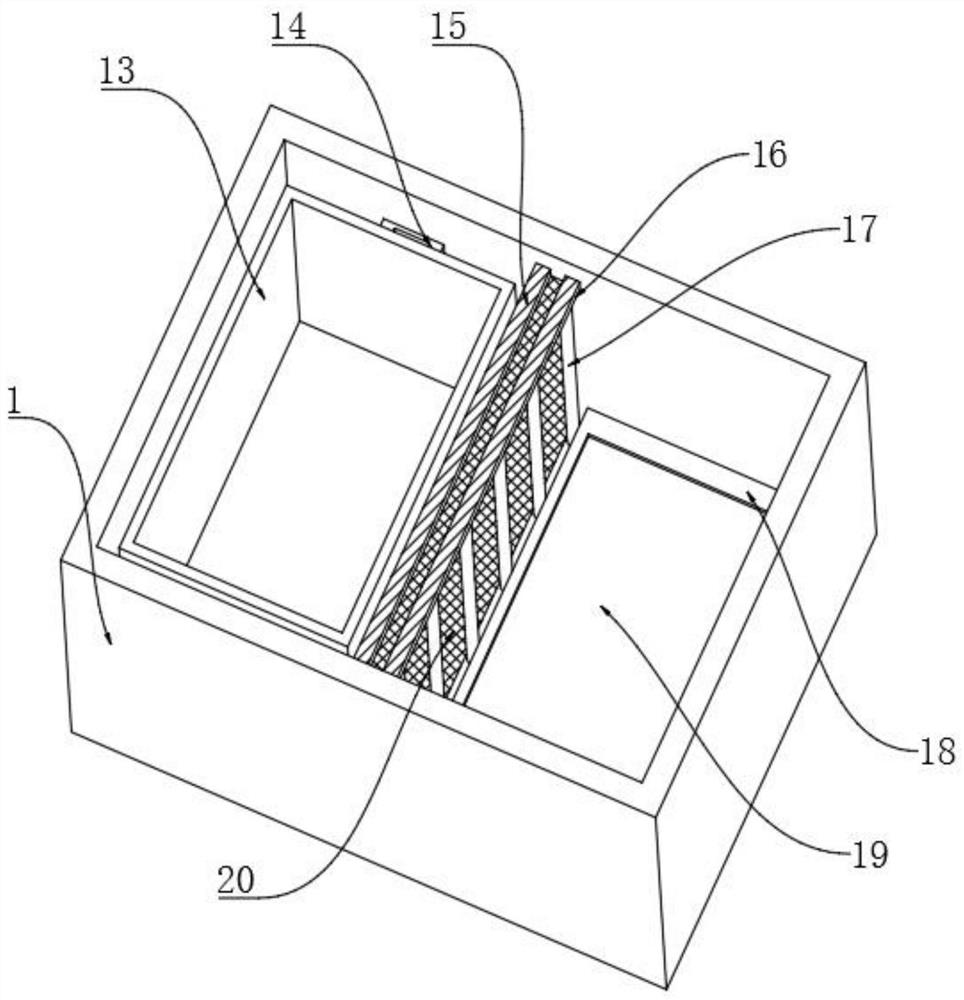

[0028] Smart trash can, in order to make the smart trash can open automatically, such as figure 1 , figure 2 , Figure 5 As shown, it includes a dustbin 1; the outer wall of one side of the dustbin 1 is fixedly connected with an ultrasonic sensor 8 by screws; the outer wall of the top of the dustbin 1 is connected with an electric baffle 2 through a hinge; Bottom plate 18; the inner wall of one side of the bottom plate 18 is processed with accommodating groove 19; the inner wall of one side of the accommodating groove 19 is placed with a garbage can 13; the outer walls of the garbage can 13 both sides are fixed with handles 14 by screws; The control steering gear 10 is connected; the electric baffle 2 and the ultrasonic sensor 8 are electrically connected to the control steering gear 10; the ultrasonic sensor 8 on the side of the garbage bin 1 uses ultrasonic waves to detect whether there is an obstruction in front, and when the obstruction stays for more than five seconds ...

Embodiment 2

[0035] Smart trash can, in order to facilitate the staff to recycle the garbage, such as Figure 4 As shown, the present embodiment makes the following improvements on the basis of Embodiment 1: the bottom inner wall of the dustbin 1 is fixedly connected with a fixed seat 21 by screws; the inner wall of the fixed seat 21 is slidably connected with a moving rod 23; 23 top outer walls are fixedly connected to the base plate 18 bottom outer walls by screws; the outer walls around the fixed seat 21 are provided with connecting springs 22; the fixed seat 21, the connecting spring 22 and the moving rod 23 form a mechanism with elastic force. When getting out of the trash can 13, the fixed seat 21 gives an upward force to the bottom plate 18, so that it is more labor-saving for the staff to take out the trash can 13. The fixed seat 21 has a certain height to prevent the garbage from being too heavy to crush the connecting spring 22, so as to ensure that the connecting spring 22 is alw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com