Multifunctional connector, water inlet assembly, and washing machine

A multifunctional connector and washing machine technology, applied in the field of washing machines, can solve the problems of defoaming and exhaust safety hazards, and achieve the effects of eliminating foam, preventing foam overflow, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

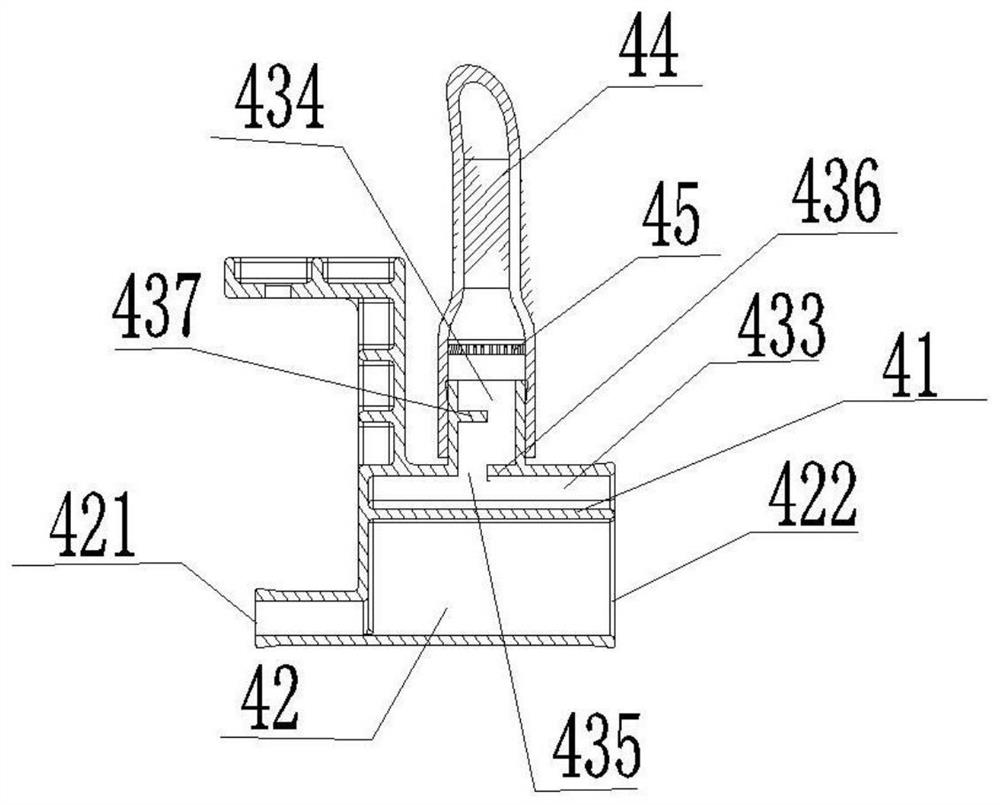

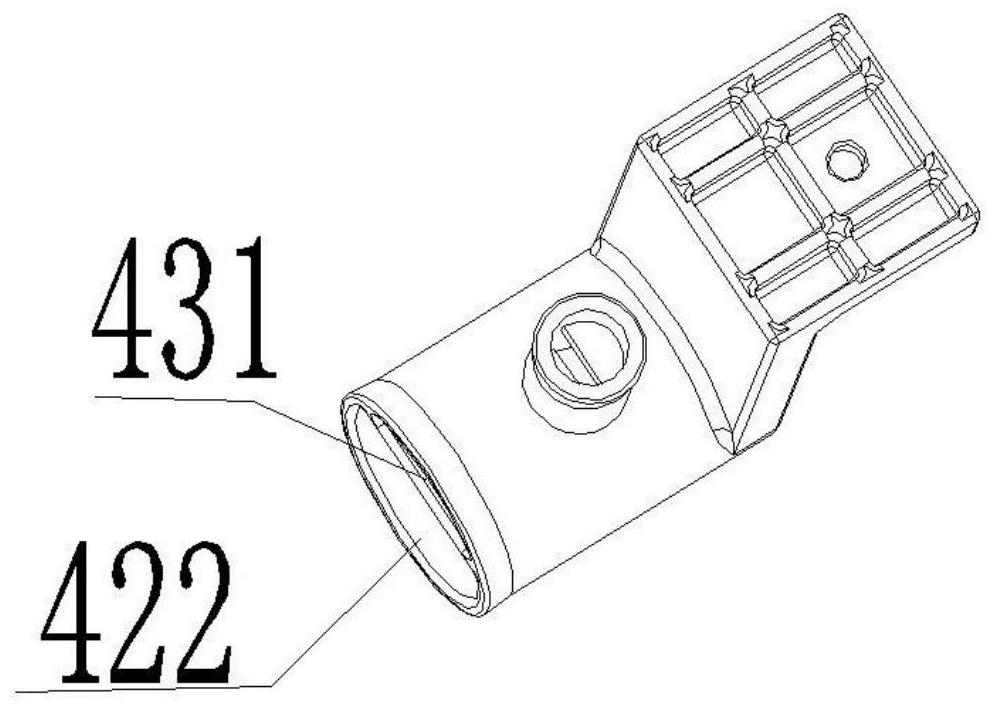

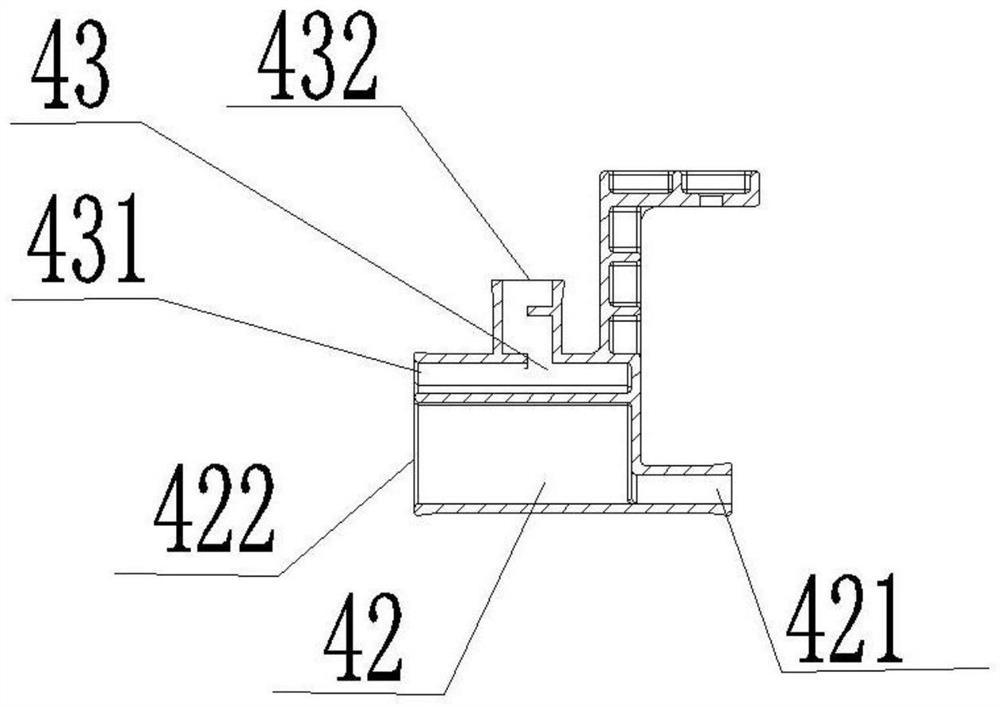

[0058] Such as Figure 1-4 As shown, the present embodiment provides a multifunctional connector, which includes: a connector body 4, the interior of the connector body 4 is divided into a first chamber 42 and a second chamber 43 that are independent of each other by a partition 41; One chamber 42 is provided with a liquid inlet 421 and a liquid outlet 422 for connecting the liquid supply flow path; the second chamber 43 is provided with an air inlet 431 and an exhaust port 432 for connecting exhaust and / or gas liquid mixture flow path; a bubble-breaking structure that can pierce bubbles is formed on the inner wall of the second chamber 43 between the air inlet 431 and the exhaust port 432; the exhaust port 432 is located at a position higher than that on the joint body 4 Or equal to the position of the air inlet 431 on the joint body 4, the bubble breaking structure is higher than or equal to the position of the air inlet 431, the liquid formed after the bubbles are pierced b...

Embodiment 2

[0068] Such as Figure 5 As shown, this embodiment provides a water inlet assembly, which includes the water inlet connector in Embodiment 1. Preferably, the water inlet assembly also includes: a water inlet hose 7, a water inlet pipe 5 and an exhaust pipe, wherein: Water inlet hose 7, one end of which is connected to the liquid inlet 421 of the multifunctional connector, and the other end is connected to the water source; water inlet pipe 5, one end of which is connected to the liquid outlet 422 of the multifunctional connector, and the other end is connected to the water inlet Connected; Exhaust pipe, its one end is connected with water inlet 2, and its other end is connected with the air inlet 431 of multifunctional joint. Preferably, the water inlet pipe 5 and the exhaust pipe share the same pipe. Preferably, the water inlet pipe 5 adopts a corrugated pipe, which has a good effect of shock absorption and noise reduction in the process of water intake, and reduces bending ...

Embodiment 3

[0071] Such as Figure 6-7 As shown, this embodiment provides a washing machine, which has the water inlet joint in embodiment 1 or the water inlet assembly in embodiment 2.

[0072] Preferably, the washing machine also includes an overflow assembly for discharging foam and / or water overflowing from the outer tub 1 out of the washing machine. A connected overflow pipe 8; a drainage assembly 10 for discharging water from the washing machine, wherein the drainage assembly 10 is provided with an overflow interface 9, and the other end of the overflow pipe 8 communicates with the overflow interface 9 on the drainage assembly 10. Preferably, the overflow port 3 is arranged above the horizontal centerline of the outer cylinder 1 .

[0073] Preferably, the washing machine preferably includes a control module, and the control module includes a controller and a motor load monitoring device, wherein,

[0074] The motor load monitoring device feeds back the monitored value to the contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com