Anti-scouring energy dissipation wall of hydraulic engineering overflow dam

A technology for water conservancy projects and overflow dams, which can be used in water conservancy projects, dams, marine engineering and other directions to solve problems such as scouring of buildings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

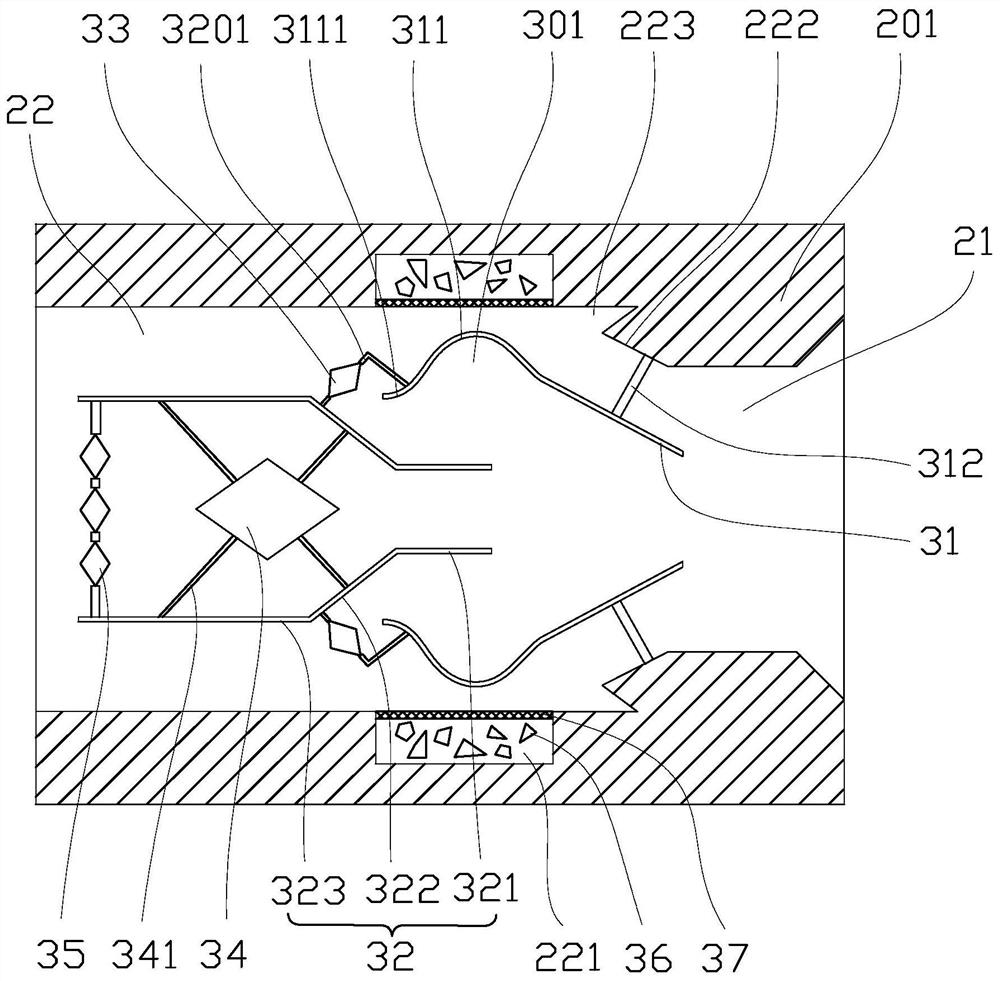

[0030] The following is attached Figure 1-2 The application is described in further detail.

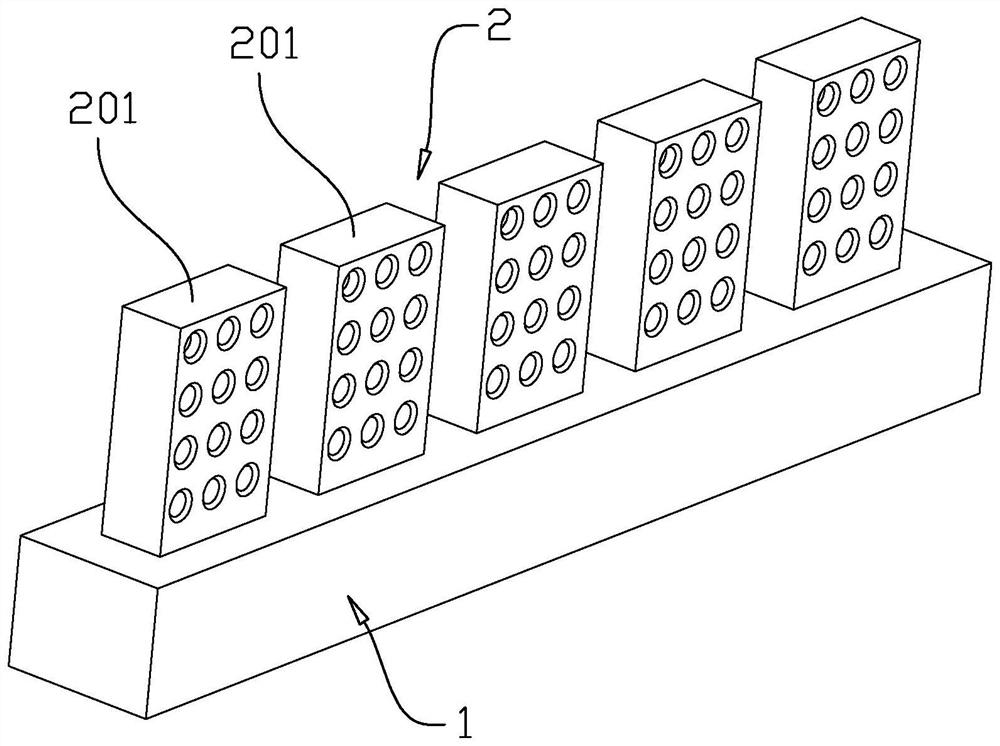

[0031] The embodiment of the application discloses an anti-scouring energy-dissipating wall of an overflow dam of a water conservancy project. refer to figure 1 , the energy dissipation wall includes the foundation 1 poured in concrete in the river bed and the retaining wall 2 fixed on the foundation 1, the foundation 1 is in the shape of a cuboid, the length direction of the foundation 1 is perpendicular to the impact direction of the water flow, and the retaining wall 2 consists of It is composed of several unit walls 201, and the several unit walls 201 are uniformly distributed along the length direction of the foundation 1, and gaps are left between two adjacent unit walls 201. A plurality of unit walls 201 are used to form the retaining wall 2, and when the water flow passes through the retaining wall 2, part of the water flow will pass through the gap between two adjacent uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com