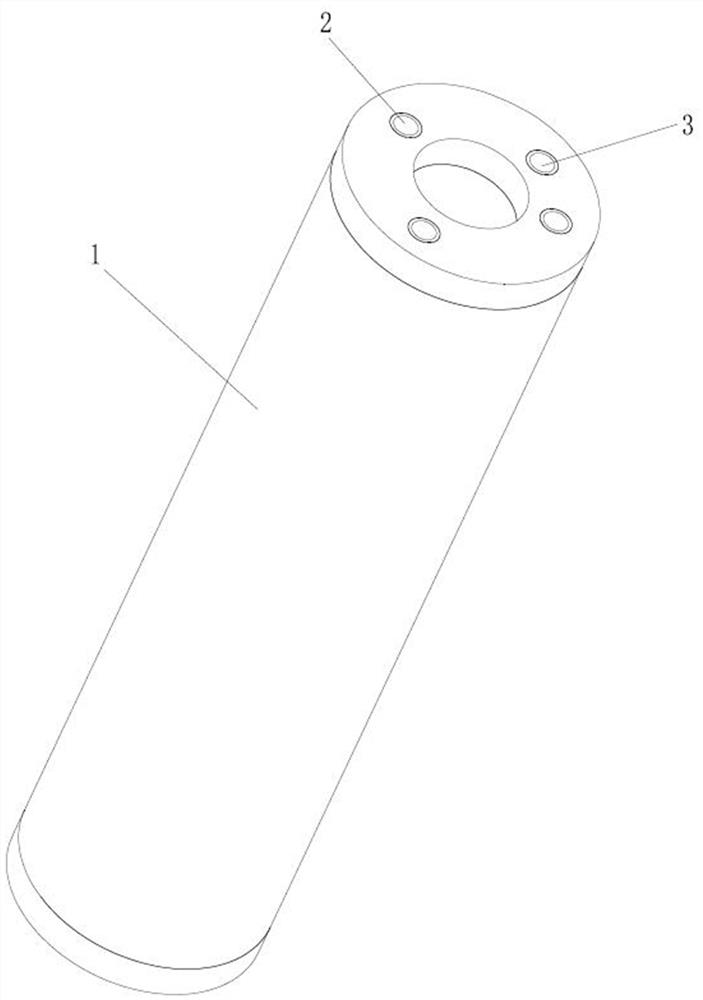

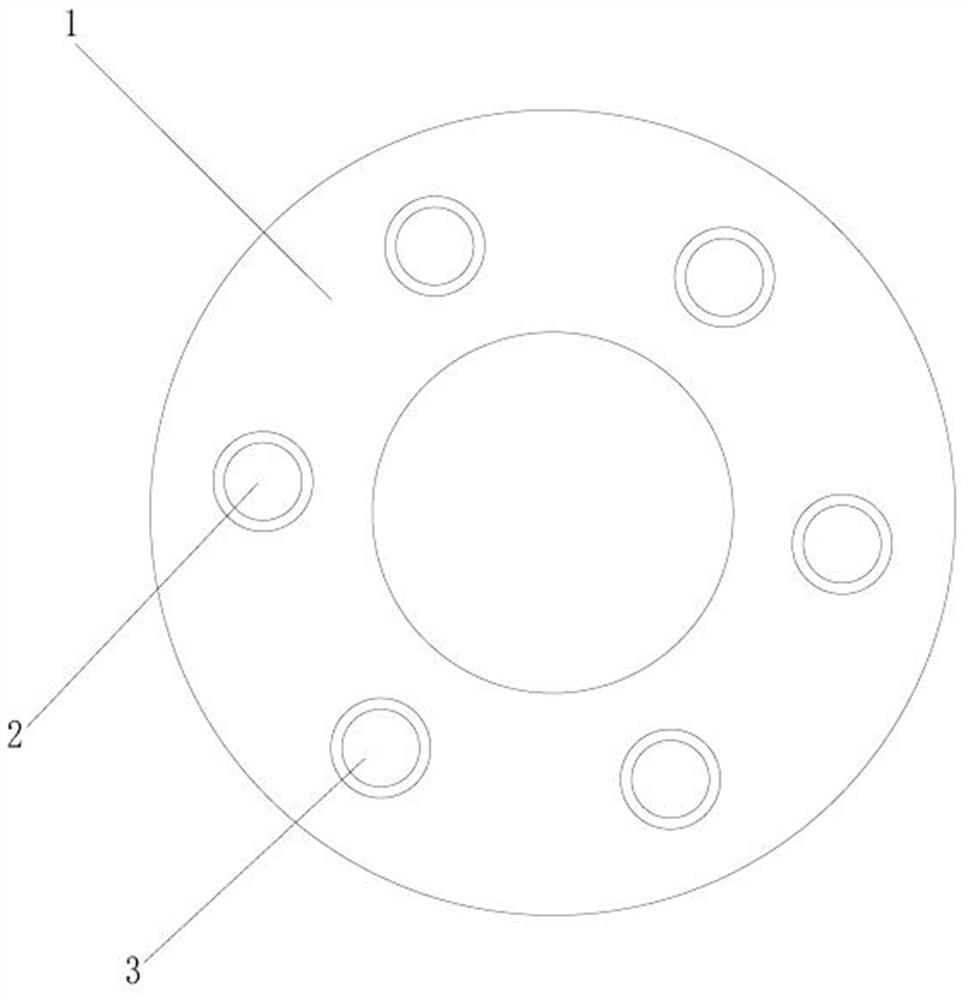

A prestressed concrete pipe pile with high load bearing and pullout resistance

A concrete pipe pile, prestressing technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problem of affecting the pullout performance of prestressed concrete pipe piles, the pile body cannot be effectively integrated, and the connection joints of the pile body are weak. and other problems, to achieve the effect of improving the pullout resistance, high bearing capacity and high pullout resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

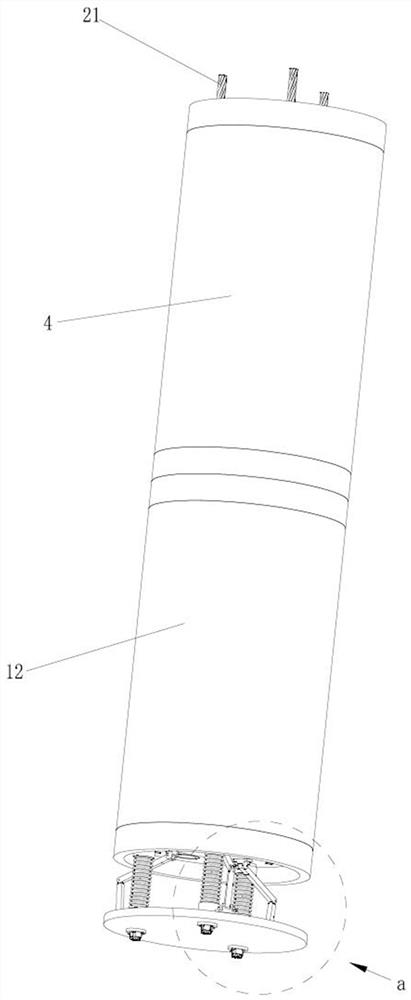

[0075] Simultaneously, in order to further improve the load-bearing and pull-out performance of a prestressed concrete pipe pile of the present invention, we further improve the structure of the pipe pile body 1, for example, as the third embodiment of the present invention, as image 3 As shown, a kind of prestressed concrete pipe pile provided in this embodiment, the pipe pile body 1 in its structure comprises:

[0076] A first pile of 4, such as Figure 4-6 As shown, each first pile 4 is made up of the first steel cage 5 and the first pile body 6 of the cylinder formed on the first steel cage 5 by pouring concrete;

[0077]Wherein, the first reinforcement cage 5 includes a plurality of first main steel bars 7 independently extending in the longitudinal direction of the first pile body 6, three first steel pipes 8 extending in the longitudinal direction of the first pile body 6, and the first main steel bars 8 extending in the longitudinal direction of the first pile body 6....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com