Novel building anti-seismic base

A new type of technology for construction, applied in the direction of buildings, building components, building types, etc., can solve the problems of corrosion or oxidation of anti-seismic bearings, reduce the service life of anti-seismic bearings, reduce the anti-seismic effect of anti-seismic bearings, etc., to achieve the improvement effect, The effect of improving the seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

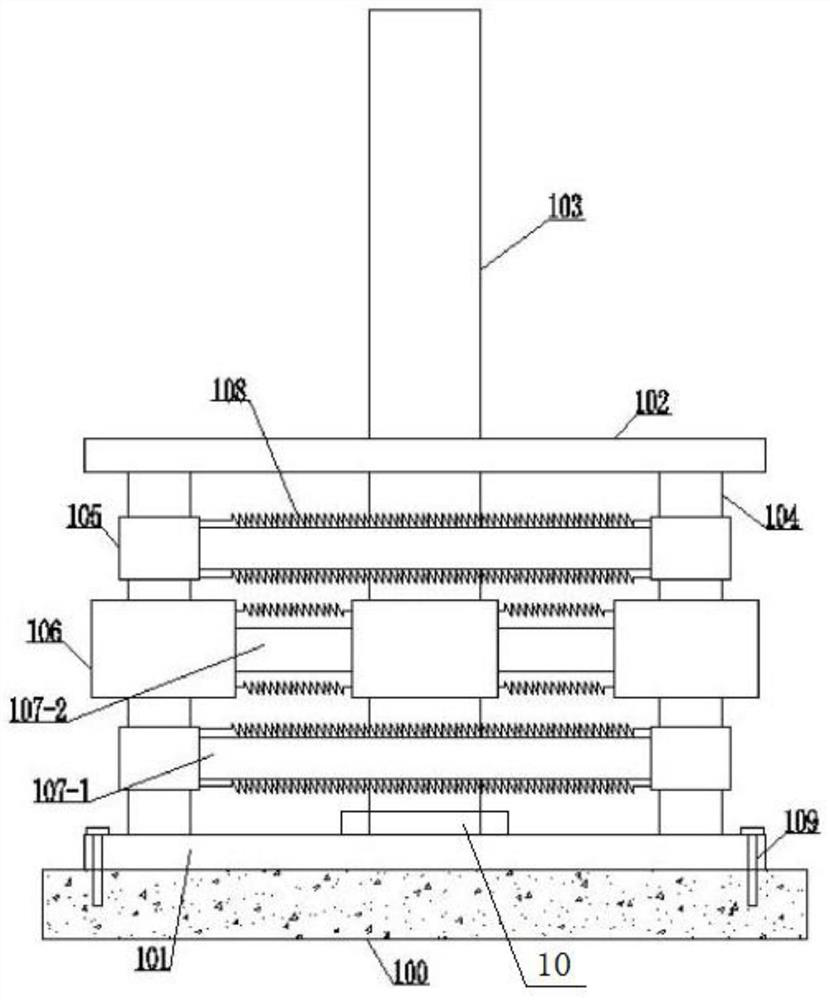

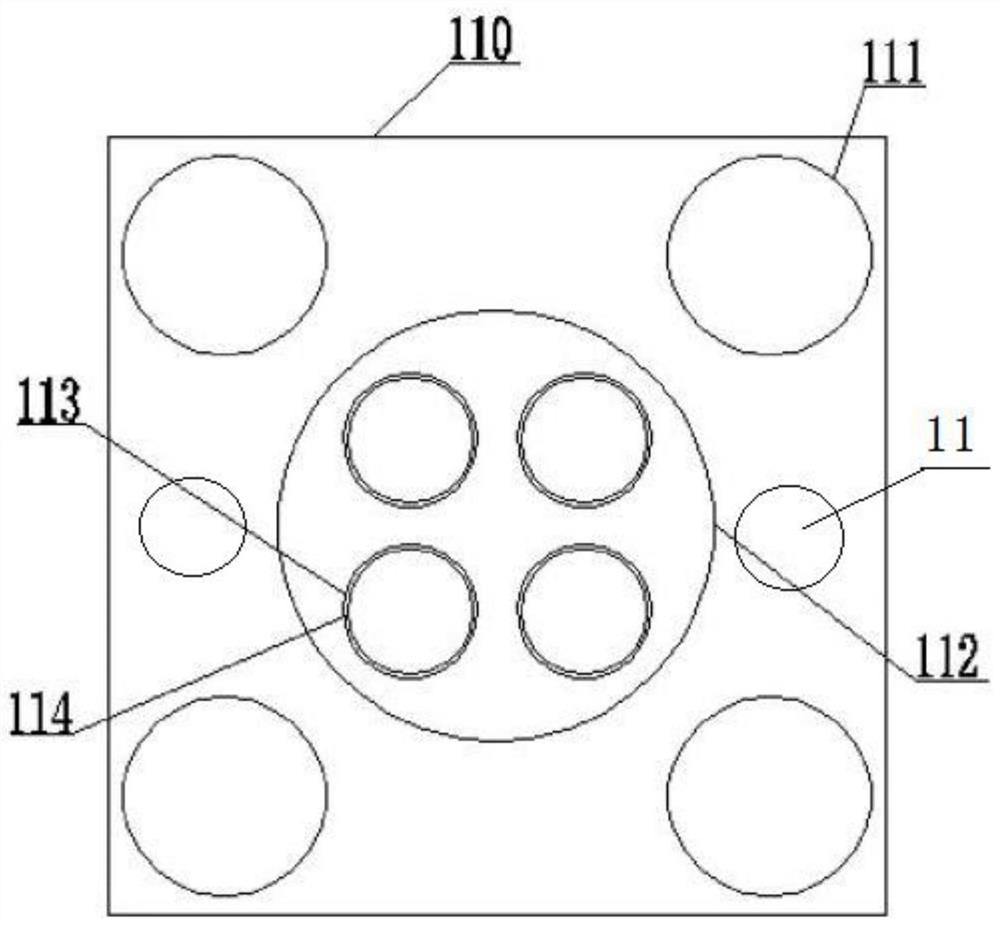

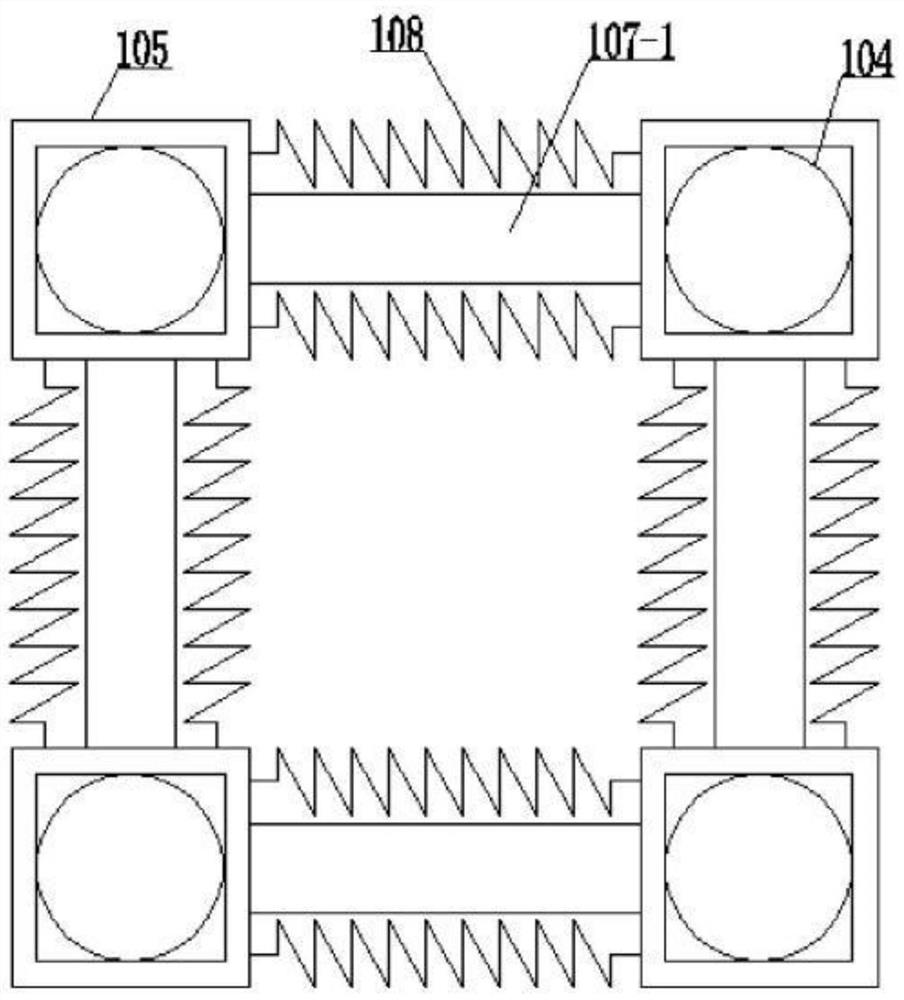

[0022] A new type of anti-seismic base for buildings, such as Figure 1-6 As shown, it includes a concrete foundation 100, a lower supporting steel plate 101, an upper supporting steel plate 102, and a main steel column 103. The lower supporting steel plate 101 is fixed on the concrete foundation 100, and the main steel column 103 passes through the upper The central position of the supporting steel plate 102 is fixed at the central position of the lower supporting steel plate 101, and a longitudinal steel column 104 is fixedly installed between the upper surface of the lower supporting steel plate 101 and the lower surface of the upper supporting steel plate 102, and the outer side of the longitudinal steel column 104 is The wall is nested with a square column I 105 and a square column II 106, the outer wall of the main steel column 103 is nested with the square column II 106, and the two adjacent vertical steel columns 104 correspond to the square columns one by one. A horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com