Multi-load carrying robot group multi-target task allocation scheduling optimization method

A technology of task allocation and optimization method, applied in the field of manufacturing workshop scheduling, which can solve problems such as system deadlock, power supply of carrier robots, and path conflicts of carrier robots.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0156] In this embodiment, multiple sets of simulation experiments are carried out to compare 8 (1*2*2*2) combinations of the traditional NIPS strategy and the scheduling strategy of the present invention.

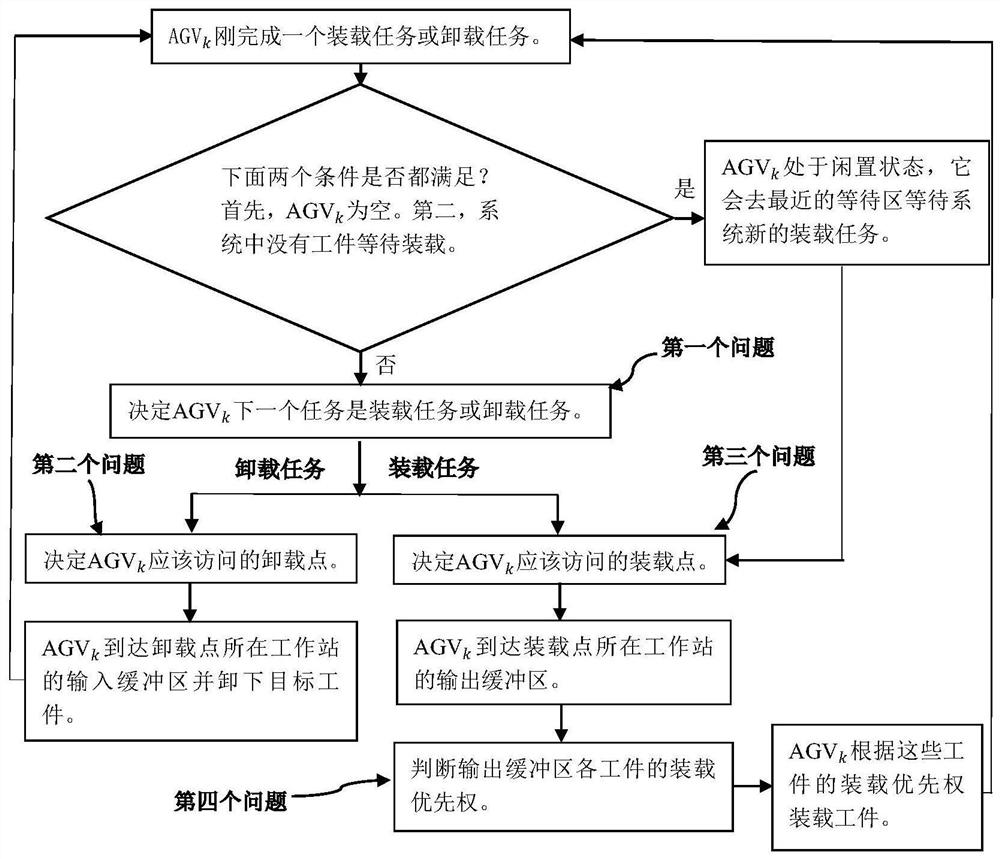

[0157] For the task selection problem, Ho Y C, Chen S H.A simulation study on the performance of task-determination rules and delivery-dispatching rules formultiple-load AGVs[J].International Journal of Production Research 2006,44(20):4193-4222.中 Three single-attribute rules are proposed and the performance among them is compared. Simulation results show that Drop-Task-First (DTF) has the best production performance. Therefore, the task selection rule adopted in this embodiment is the unloading priority rule. Under this rule, if the delivery robot is in the loading state, it will give priority to the unloading task.

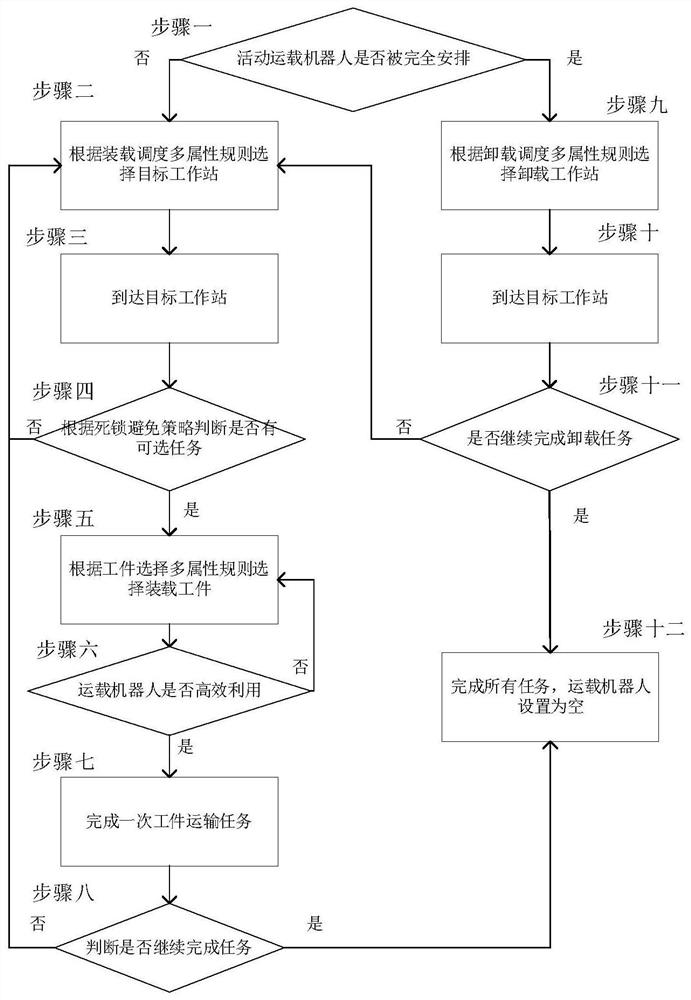

[0158] For loading scheduling, two rules are selected in this embodiment, the first is the Multi-Attribute Rule for Pickup dispatching problem (MARP) in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com