Multi-directional material distributing and conveying production line and production device and method of pork stuffing dumplings

A production line and conveying direction technology, which is applied to cleaning methods using liquids, conveyors, conveyor objects, etc., can solve problems such as low material distribution efficiency, large errors, and extremely unbalanced material volume, and achieve the effect of increasing the length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

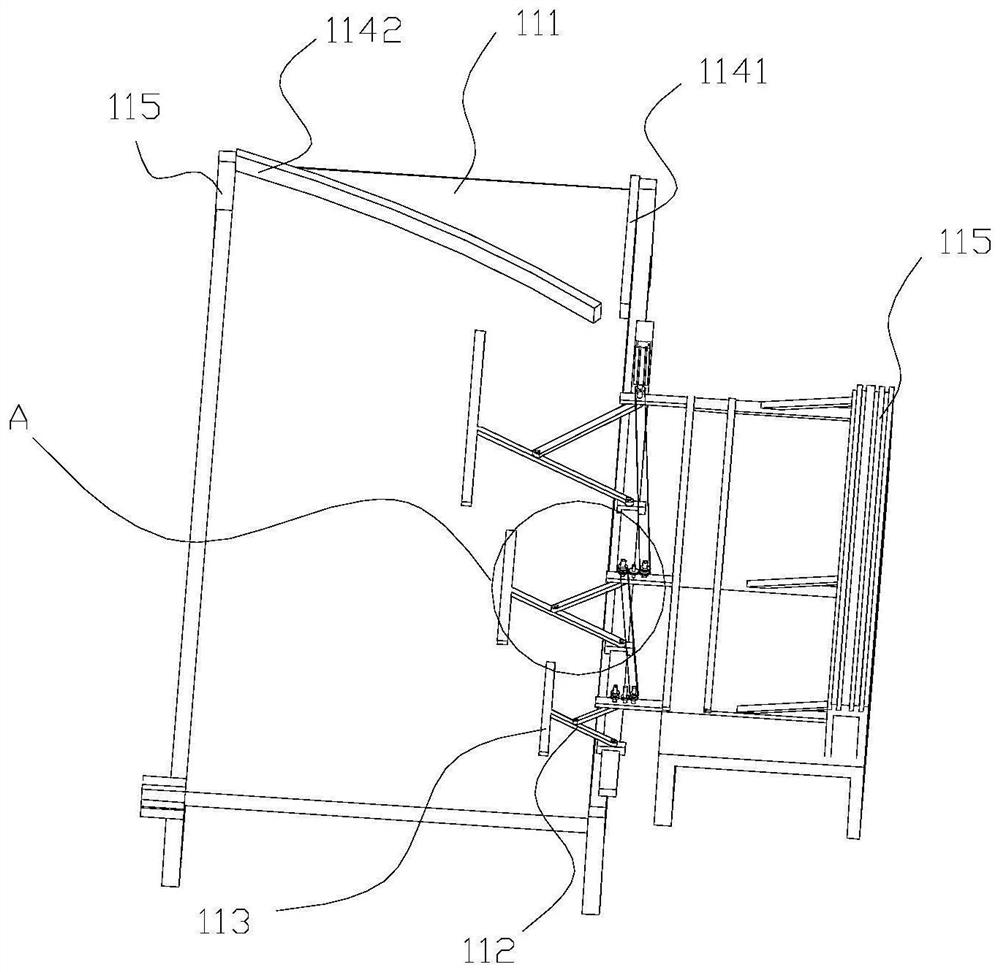

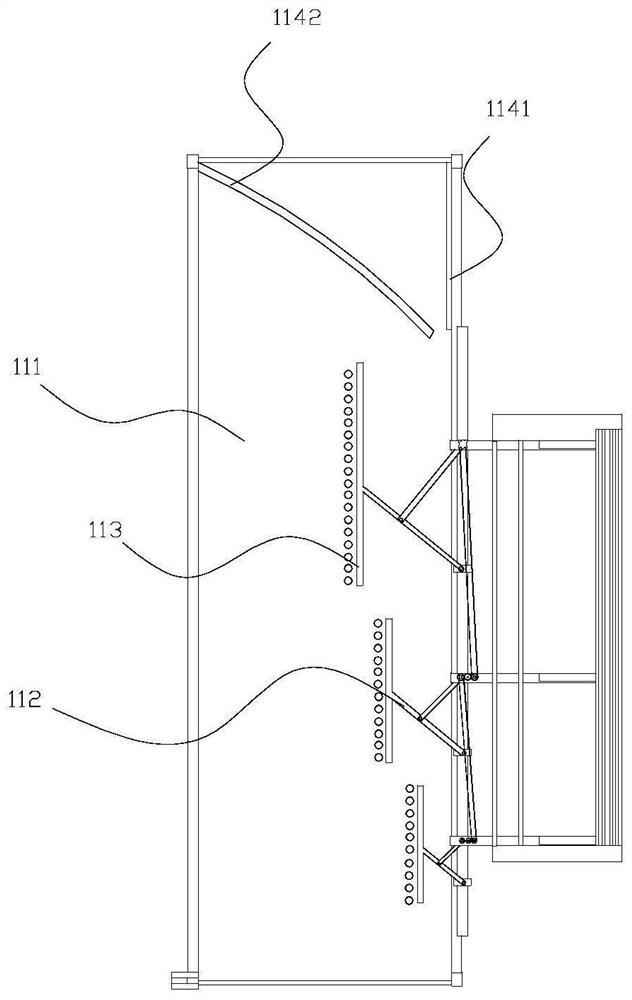

[0068] Such as Figure 1-3 As shown, this embodiment discloses a multi-directional material distribution and conveying production line, including a belt conveying device 111, an ejection mechanism 112, an ejecting plate 113, and a guide assembly. The belt conveying device 111 is used to convey materials. The two sides in the width direction of the belt conveying device 111 are respectively the feeding side and the pushing out side. The belt conveying device 111 of the present invention is prior art.

[0069] Guide assembly is arranged on the initial end of belt conveyer 111, comprises first guide plate 1141, second guide plate 1142, and first guide plate 1141 is arranged on the feed side of its initial end of belt conveyer 111 and its length direction and belt conveying The delivery direction of the device 111 is consistent, and one end of the second guide plate 1142 is arranged on the push-out side of the starting end of the belt conveyor 111, and the other end of the second...

Embodiment 2

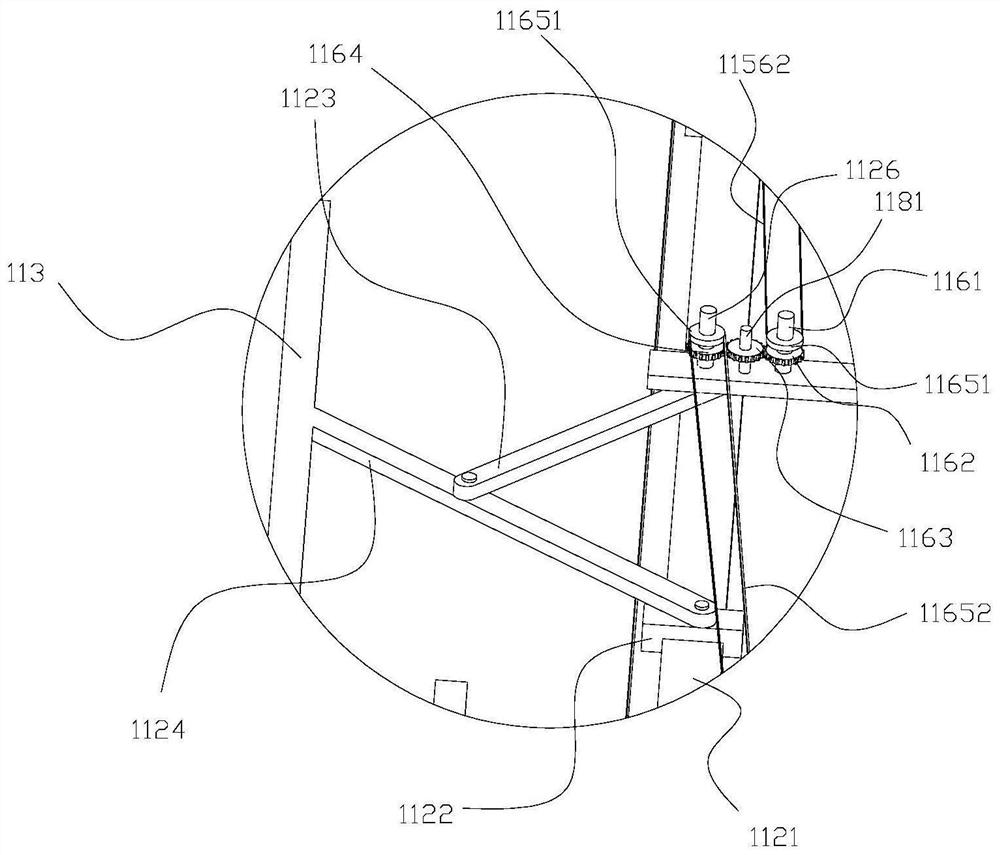

[0076] Such as figure 2 As shown, the difference between this embodiment and the above-mentioned embodiments is that the ejection mechanism 112 includes a guide track 1121, an ejection slider 1122, a first ejection connecting rod 1123, a second ejection connecting rod 1124, the guide of the guide rail 1121 and the belt conveying device The conveying direction of 111 is consistent, and pushes out slide block 1122 and guide rail 1121 sliding fits, and one end of the first push-out connecting rod 1123 rotates with frame 115, and the other end of the first push-out connecting rod 1123 and the middle section of the second pushing out connecting rod 1124 Hinged, one end of the second push-out connecting rod 1124 is hinged with the push-out slider 1122 , and the other end of the second push-out connecting rod 1124 is connected with the corresponding push-out plate 113 .

[0077] The present invention specifically uses the output shaft of the push-out motor 1125 to be connected to th...

Embodiment 3

[0080] Such as figure 2 As shown, the difference between this embodiment and the foregoing embodiments is that the ejection mechanism 112 includes a first ejection connecting rod 1123, a third ejection connecting rod 1127, a guide rail 1128, and an ejection rod 1129, and the guiding and belt conveying of the guide rail 1128 The width direction of device 111 is consistent, and one end of the first push-out connecting rod 1123 is rotated with the frame 115, and the other end of the first pushing-out connecting rod 1123 is hinged with one end of the third pushing-out connecting rod 1127, and the other end of the third pushing out connecting rod 1127 is hinged. One end is hinged with one end of the push-out rod 1129 , the push-out rod 1129 is slidingly matched with the guide rail 1128 and the other end of the push-out rod 1129 protrudes from the guide rail 1128 to connect with the corresponding push-out plate 113 .

[0081] The difference between this embodiment and the above-men...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com