Drum screen for coal gangue processing

A technology of coal gangue and trommel screen, which is applied in the direction of filtering, using liquid separating agent, solid separation, etc. It can solve the problems of increased cleaning time, inconvenient protection of the drum, and large dust, so as to improve the buffering effect, good working environment, and convenient The effect of spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

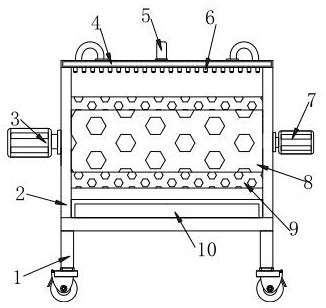

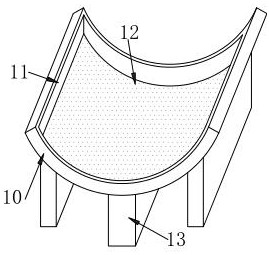

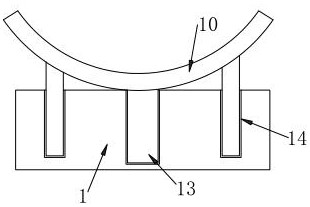

[0037] see Figure 1-7 , the present invention provides a technical solution, a trommel screen for coal gangue processing: comprising a bottom frame 1, a fixed frame 2 fixed on the upper surface of the bottom frame 1, a first motor 3 is installed on the side of the fixed frame 2, the first motor The output shaft of 3 runs through the fixed frame 2 and is fixedly connected with the first roller 8. The outer wall of the first roller 8 is provided with a plurality of first through holes 23. The inside of the upper surface of the fixed frame 2 is a hollow structure, and the inside of the fixed frame 2 The delivery pipe 4 is fixed, the upper surface of the fixed frame 2 is fixed with a plurality of connecting pipes 5, the inner side wall bottom surface of the fixed frame 2 is equipped with a plurality of nozzles 6, the rear surface of the chassis 1 is equipped with a water tank 16, and the inside of the water tank 16 is fixed. There is a vibrator 17 and a water pump 18, and the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com