Valve oil seal progressive die

A technology for molds and valves, which is applied in the field of valve oil seal progressive molds, and can solve problems such as batch failure, insufficient precision of progressive molds, and reduced production efficiency of valve oil seal progressive molds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

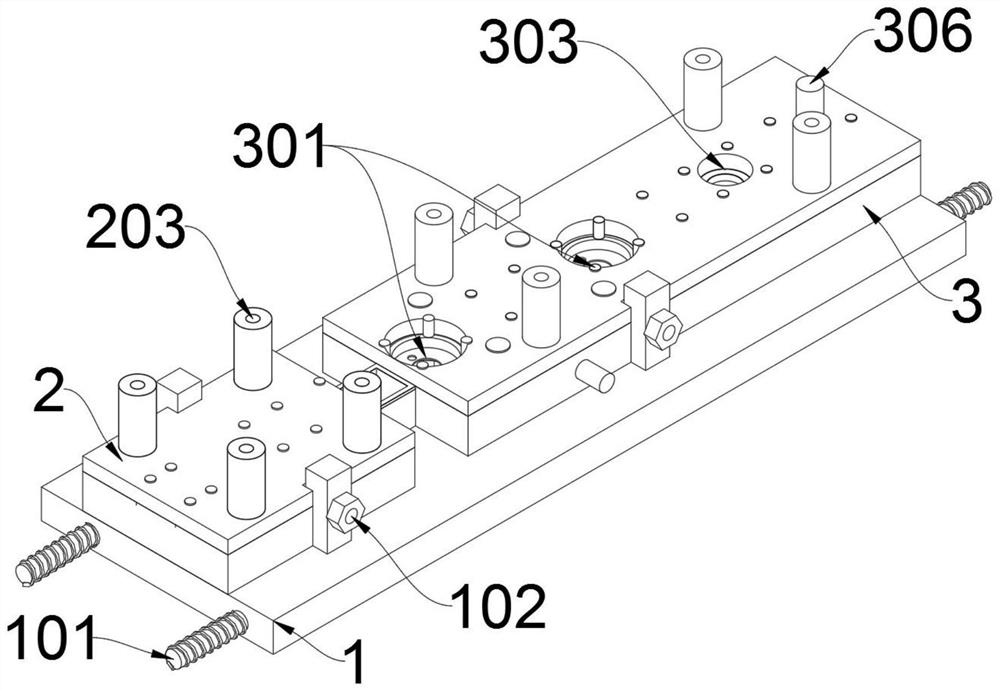

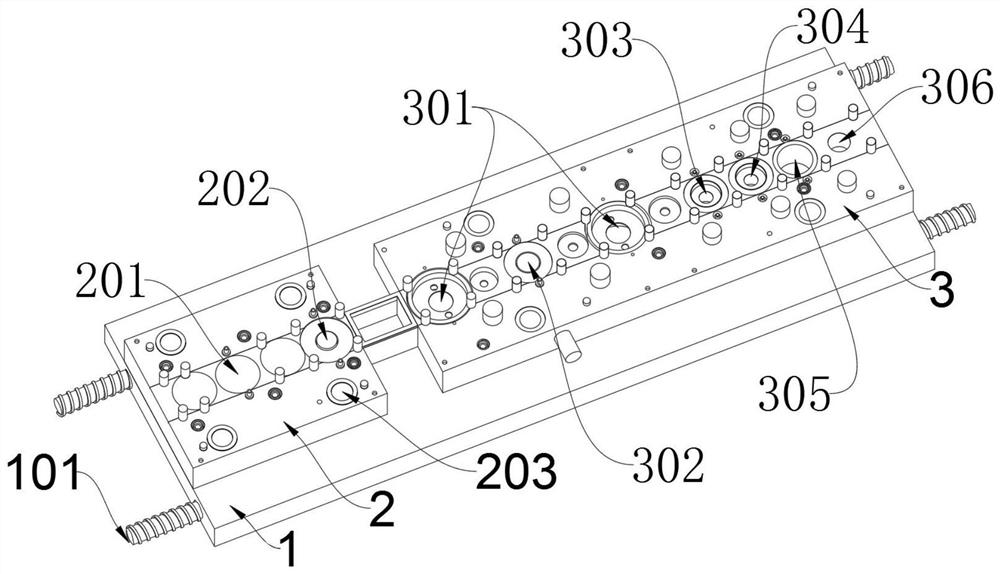

[0025] as attached figure 1 to attach figure 2 Shown:

[0026] The invention provides a valve oil seal progressive mold, comprising a base 1; the base 1 is a cuboid structure, and a small base plate 2 is fixedly installed on the left side of the center; a large base plate 3 is fixedly installed on the left and right sides of the base 1; two different The width of the small base plate 2 and the large base plate 3 are the same, and the width of the base 1 is greater than the width of the small base plate 2 and the large base plate 3; the base 1 includes a fixed cross bar 101 and a positioning buckle 102 A pair of threaded fixed crossbars 101 are installed transversely on the planes on the left and right sides of the base 1, and two sets of positioning buckles 102 are respectively installed on the outer walls of the front and rear ends of the base 1, the base 1 and the small base plate 2 It is installed in cooperation with the large base plate 3, so that it can include multipl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com