Stamping and shaping device for mold repair

A shaping device and mold repairing technology, which is applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems that the manipulator cannot check the state of the workpiece well and intuitively, affects the line of sight, and interferes with the operator, so as to achieve low maintenance cost in the later stage , Improving production safety and shortening the transportation distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

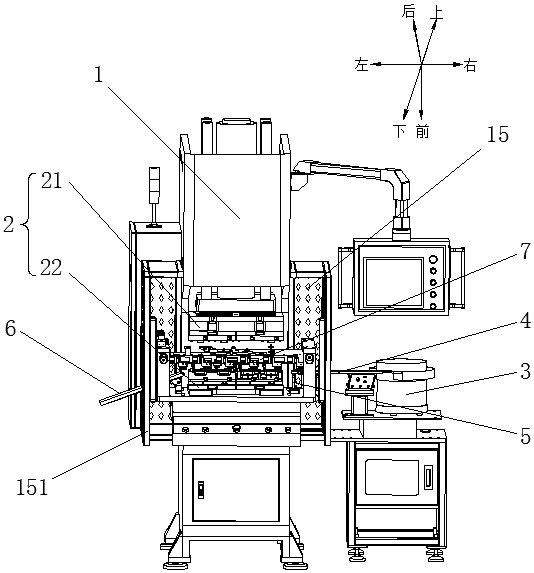

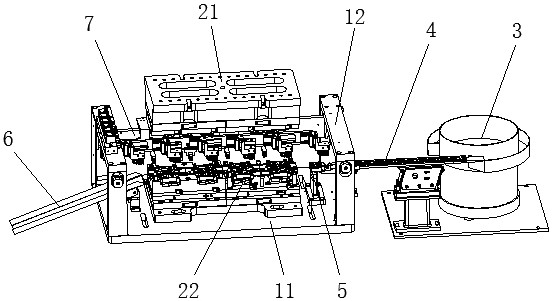

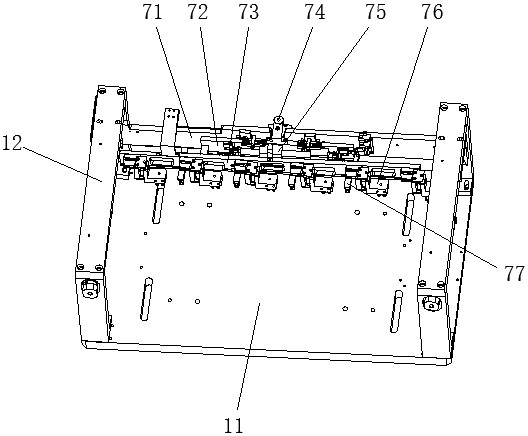

[0031] See Figure 1 to Figure 6 In the present invention, the punching and shaping device convenient for mold repairing includes a press 1 and a shaping die 2; the pressing machine 1 can be a hydraulic press or a stamping machine; the shaping die 2 includes a correspondingly matched upper die 21 and a lower die 22; The upper mold 21 is fixedly arranged on the output head of the press 1, and the lower mold 22 is fixedly arranged on the working platform 11 of the press 1; the vibrating plate 3, the conveying channel 4, the positioning assembly 5, The shaping mold 2 and the discharge channel 6; the shaping mold 2 is provided with 4 shaping stations; the discharge port of the vibrating plate 3 is correspondingly connected with one end of the conveying channel 4; the working platform 11 is fixedly equipped with a Frame 12, the mounting frame 12 is provided with a handling assembly 7 for synchronous handling; the handling assembly 7 is used to transport the product to be shaped on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com