Integrated circuit pin cutting machine

An integrated circuit and cutting machine technology, which is applied to the parts of grinding machine tools, machine tools suitable for grinding workpiece edges, manufacturing tools, etc., can solve the problem of no post-processing of cutting feet, unstable circuit operation, and inability to use different sizes Integrated circuit board and other problems to avoid circuit instability and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to facilitate the understanding of the present invention, the present invention will be described more fully below with reference to the associated drawings. A preferred embodiment of the invention is shown in the drawings. However, the present invention can be embodied in many different forms and is not limited to the embodiments described herein. Rather, these embodiments are provided so that the disclosure of the present invention will be thorough and complete.

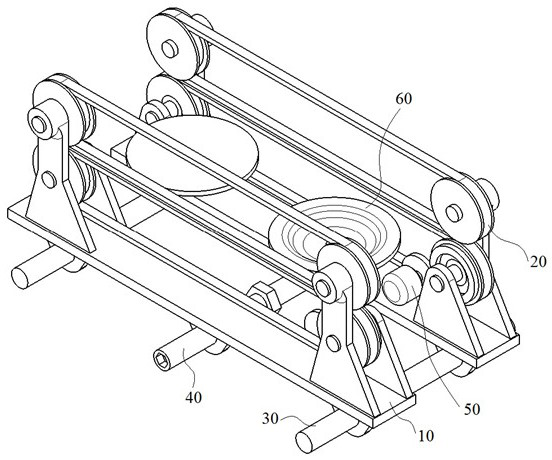

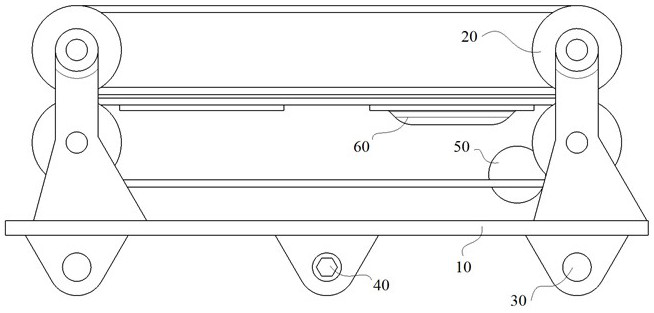

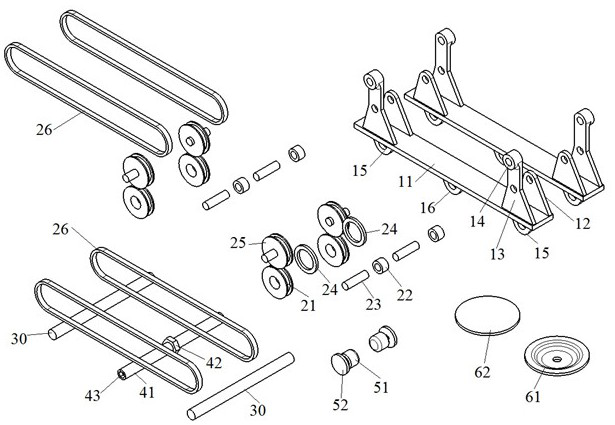

[0019] see Figure 1-Figure 3 The shown integrated circuit foot cutting machine includes a support 10, a transmission part 20, a guide rod 30, an adjustment part 40, a drive part 50 and a cutting part 60, the support 10 has a pair, the transmission part 20 is installed on the support 10, and the guide rod 30 is installed at the bottom of the bracket 10 to guide the movement of the bracket 10. The adjustment part 40 is installed at the bottom of the bracket 10 to regulate the distance between the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com