Cutting type oil tank recovery device

A recovery device and cutting-type technology, which is applied in the direction of shearing devices, shearing machine accessories, maintenance and safety accessories, etc., can solve the problems of many oily impurities, easy accidental injury to human beings, and difficult recycling, so as to improve cleaning efficiency and avoid The effect of injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

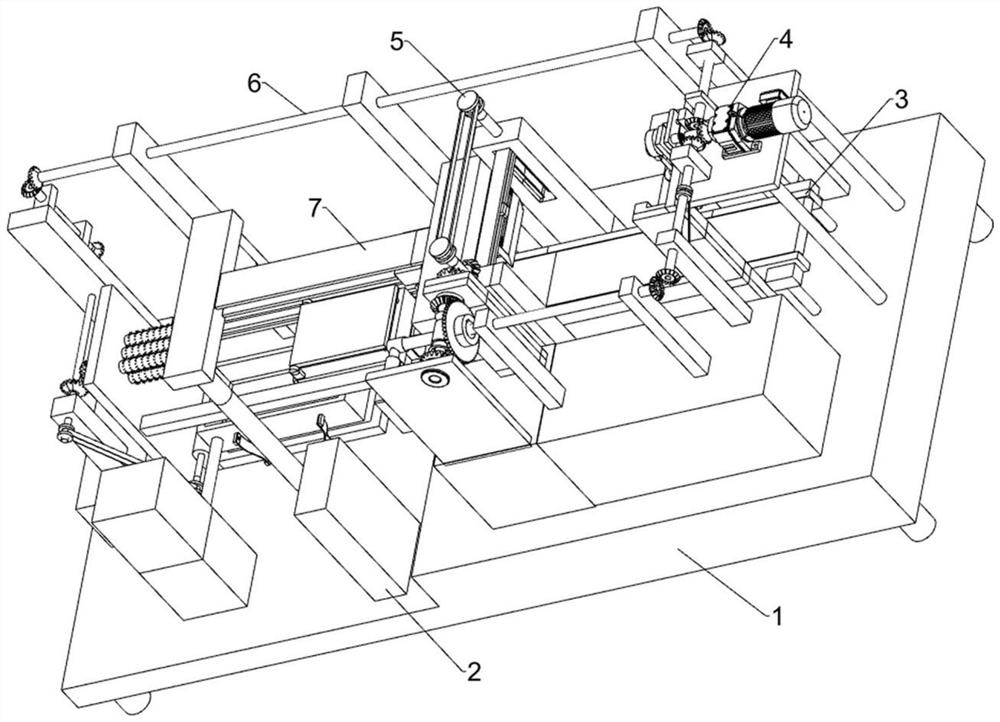

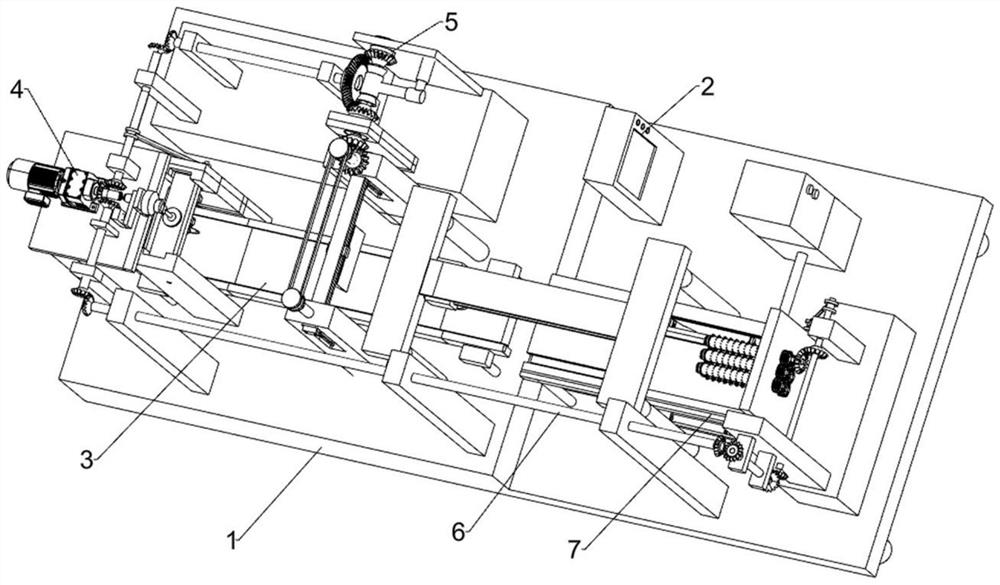

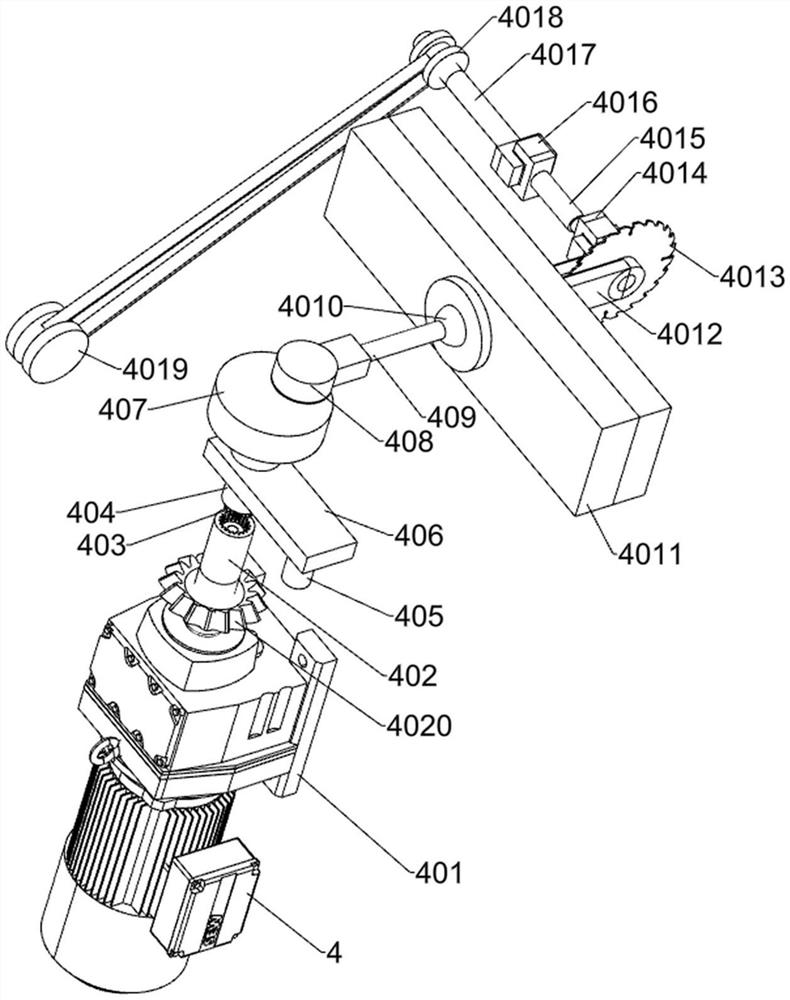

[0025] A cutting tank recovery device such as Figure 1-6 As shown, it includes workbench 1, control panel 2, conveyor belt assembly 3, cutting assembly 4, separation assembly 5, swing assembly 6 and transport assembly 7; workbench 1 is connected with control panel 2; workbench 1 and conveyor belt assembly 3 Workbench 1 is connected with cutting assembly 4; workbench 1 is connected with separation assembly 5; workbench 1 is connected with swing assembly 6; workbench 1 is connected with transport assembly 7; cutting assembly 4 is connected with separation assembly 5 connected; the cutting assembly 4 is connected with the rocking assembly 6.

[0026] Working process: when the device is in use, first open and adjust the device through the control panel 2, then manually put the fuel tank on the conveyor belt assembly 3 on the workbench 1, cut off the fixing belt on the fuel tank through the conveyor belt assembly 3, and then separate The component 5 cuts off one side of the fuel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com