Automatic rotary clamping tool for welding L-shaped steel structure heavy-load bridge

An automatic rotation, steel structure technology, applied in the field of clamping tooling, can solve the problems of hidden safety hazards, affecting welding accuracy, time-consuming and laborious, etc., to achieve the effect of simple structure, personal safety, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018]The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

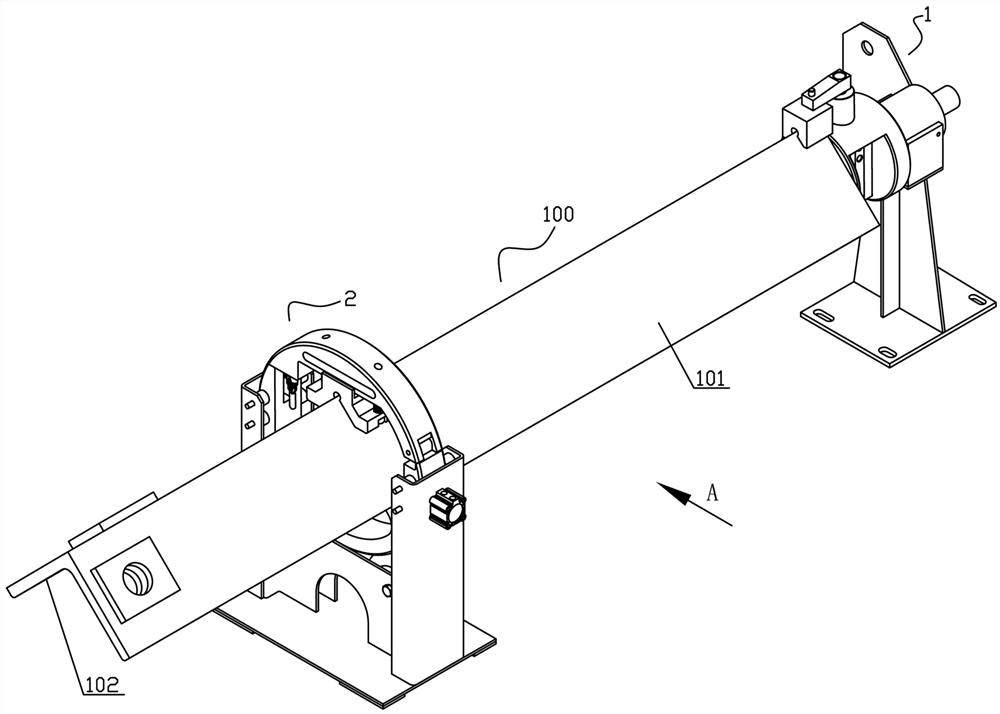

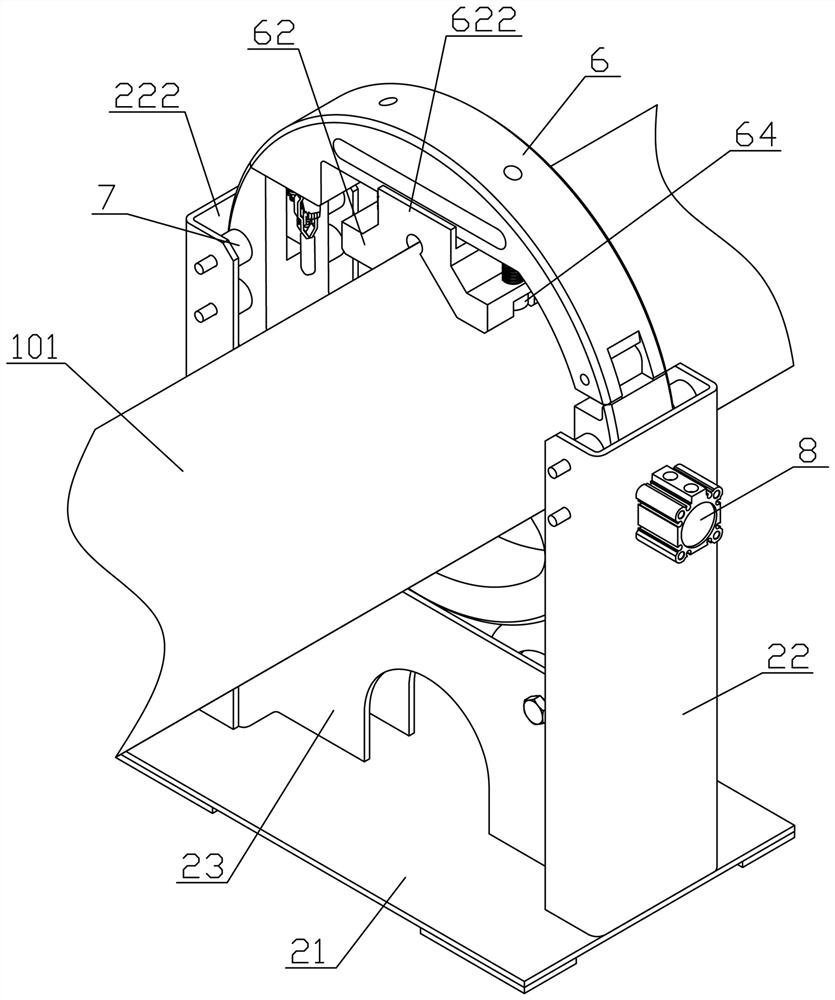

[0019]Such asfigure 1 withFigure 7As shown, the automatic rotating clamping tool for welding L-shaped steel structure heavy-duty bridges described in this embodiment is composed of a first clamping rotating device 1 and a second clamping rotating device 2 arranged at intervals in the front and rear. The L-shaped steel structure heavy-duty bridge 100 can be clamped in the first clamping rotating device 1 and the second clamping rotating device 2.

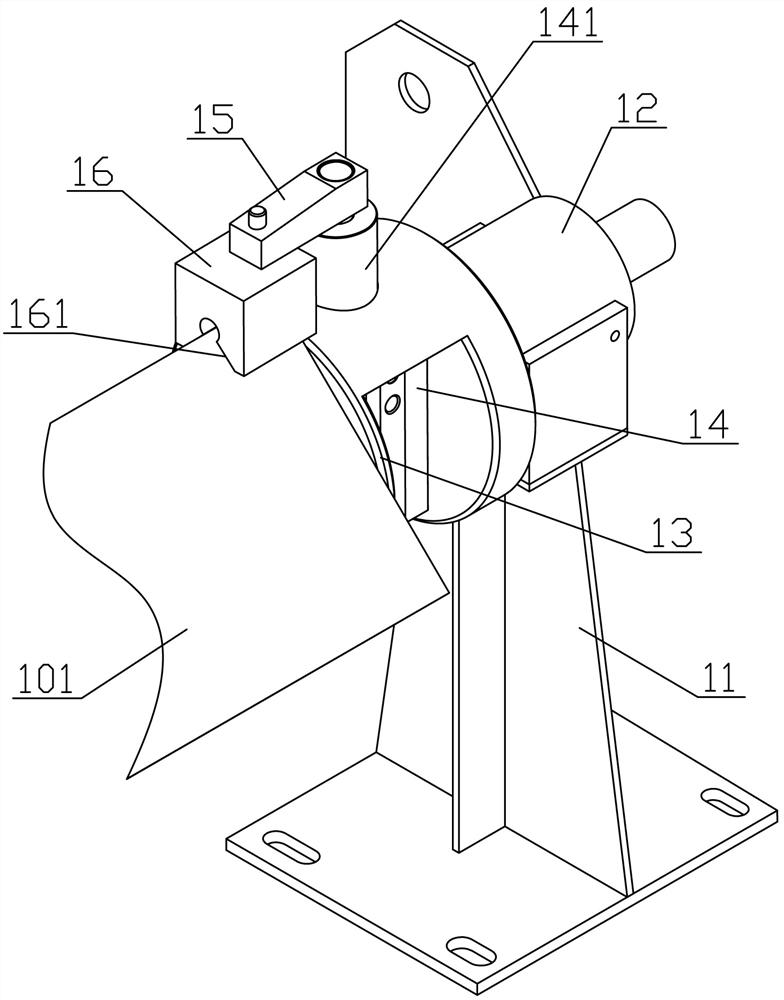

[0020]Such asimage 3 withFigure 7As shown, the structure of the first clamping and rotating device 1 described in this embodiment includes: a mounting frame 11 on which a drive motor 12 is fixedly arranged, and a fixed shelving block 13 is fixedly mounted on the motor shaft of the drive motor 12 The top surface of one end of the fixed shelving block 13 is an L-shaped shelving s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com