A mold for making prestressed concrete pipe piles

A concrete pipe pile and prestressing technology, which is used in molds, reinforcement molding, ceramic molding cores, etc., can solve the problems of mold backlog occupying workshop space, the process of mold replacement is complicated and time-consuming, and the weight and length of molds are large. Convenience, improve production efficiency, improve the effect of actual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

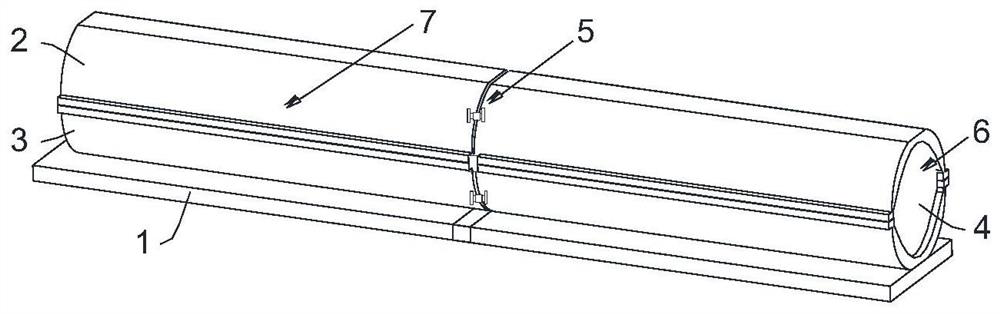

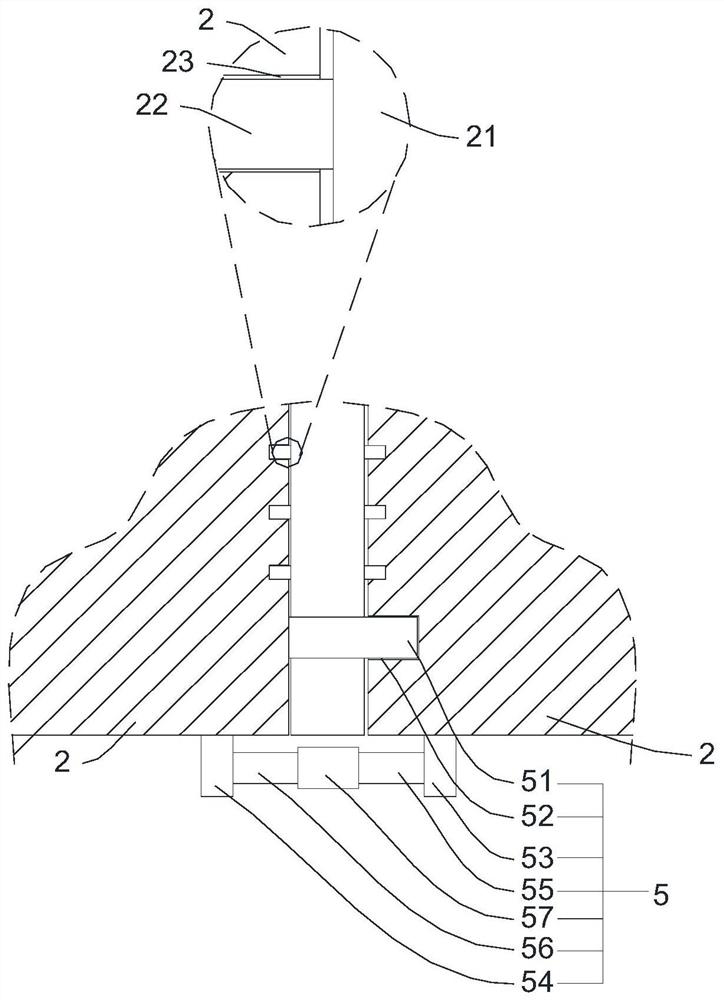

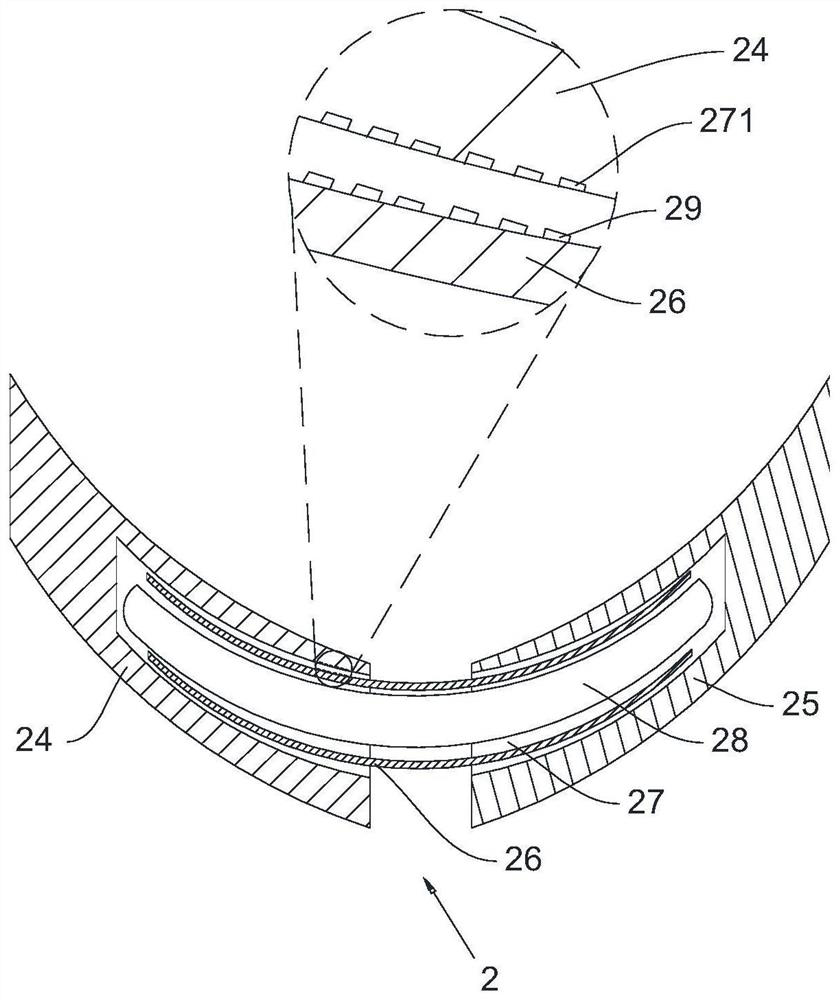

[0031] refer to figure 1As shown, it is a mold for making a prestressed concrete pipe pile disclosed by the present invention, including a mounting frame 1, the mounting frame 1 is provided with a lower forming die 3 and an upper forming die 2 corresponding to the lower forming die 3, and the upper forming die 2 and both ends of the lower forming die 3 are provided with fixed end plates 4; in order to be able to change the types of pipe piles produced without changing the mold during actual use and to improve actual production efficiency, the adjacent upper forming die 2 Fixing devices 5 are provided between the adjacent lower forming dies 3, installation devices 6 are provided between the end plates 4 and the lower forming dies 3, and connecting structures 7 are provided between the upper forming dies 2 and the lower forming dies 3. The upper forming die 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com