Rapid injection molding, demolding and separating equipment for processing negative ion antibacterial glasses shell

A negative ion antibacterial and separation equipment technology, which is applied in the direction of mechanical equipment, spring/shock absorber, vibration suppression adjustment, etc., can solve the problems of long mold processing time, unsatisfactory use effect, low mold production efficiency, etc., and achieve further improvement Heat dissipation, convenient injection molding, and improved sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

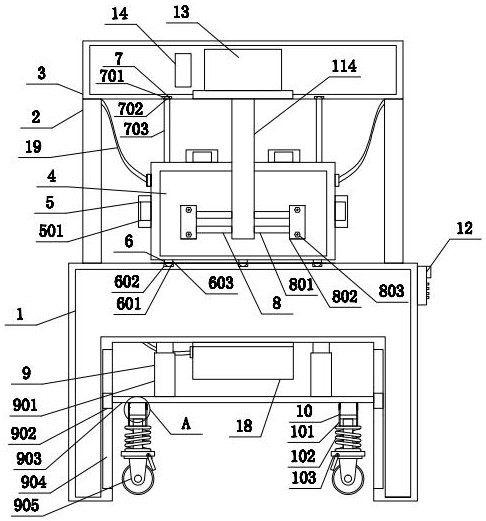

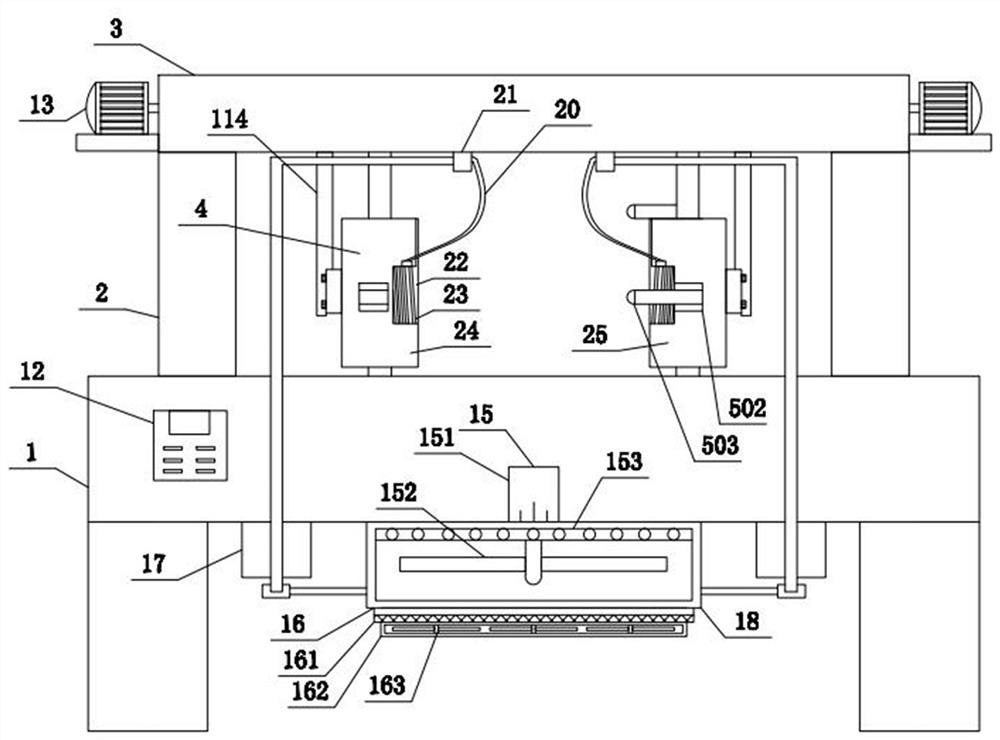

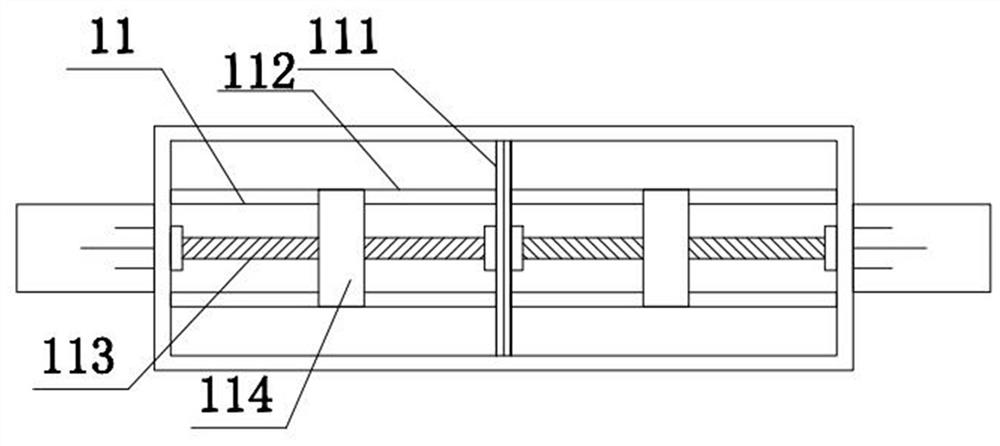

[0034] see Figure 1-5 , a kind of rapid injection mold release separation equipment for negative ion antibacterial glasses shell processing, comprising a frame 1, the lower end of the frame 1 is provided with a walking mechanism 9, and the left and right sides of the upper end of the frame 1 are fixedly connected with pillars 2 , the upper end of the pillar 2 is fixedly connected with the same top shell 3, the inner side of the top shell 3 is provided with a reciprocating assembly 11, and the end of the output shaft of the synchronous motor 13 passes through the top shell 3 and the reciprocating assembly 11 to be fixedly connected, The lower end of the reciprocating assembly 11 runs through the bottom of the top shell 3, the lower end of the reciprocating assembly 11 is provided with a reinforcement assembly 8, and the lower end of the reciprocating assembly 11 is movably connected to the first mold body 4 through the reinforcement assembly 8, and the reciprocating assembly 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com