Automatic batch stamping equipment for office documents

A batch and document technology, applied in printing, stamping, etc., can solve problems such as fast working frequency and easy to dirty documents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A batch of automatic stamping equipment for office documents, such as Figure 1 to Figure 3 As shown, it includes a first support frame 1 , a transmission mechanism 2 and a seal mechanism 3 , the top of the first support frame 1 is provided with a transmission mechanism 2 , and the top of the first support frame 1 is provided with a seal mechanism 3 .

[0058] The transmission mechanism 2 includes a motor 21, a pulley assembly 22, a fixed block 23, a rotating shaft 24, a first missing gear 25, a bevel gear 26, a first transmission assembly 27, a fixed shaft 28 and a projection 29, and the first supporting frame 1 top front A motor 21 is arranged on the side, and the output shaft of the motor 21 is connected with a first missing gear 25, and the left and right sides of the top of the first support frame 1 are connected with fixed blocks 23, and the belt pulley assembly 22 is connected in rotation between the fixed blocks 23, The front side of the drive shaft on the right...

Embodiment 2

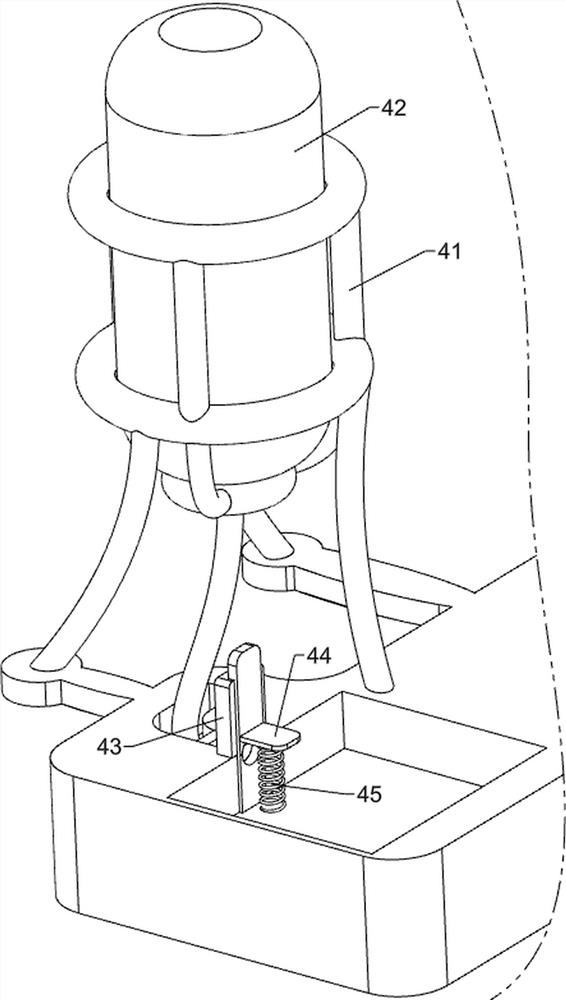

[0062] On the basis of Example 1, such as Figure 4 with Figure 5 As shown, the initial state also includes an ink filling mechanism 4, and the ink adding mechanism 4 includes a second support frame 41, an ink barrel 42, a chute block 43, a stopper 44 and a second spring 45, and the top of the first support frame 1 The left rear side is connected with a second support frame 41, the second support frame 41 is provided with an ink barrel 42, the bottom of the ink barrel 42 is connected with an ink outlet pipe, the top of the first support frame 1 is provided with a chute block 43, and the chute block 43 A block 44 is slidably connected to the top, and the block 44 cooperates with the ink outlet pipe. A second spring 45 is connected between the bottom of the block 44 and the top of the first supporting frame 1 .

[0063] The ink in the ink barrel 42 flows into the top of the first support frame 1 through the ink outlet pipe. When the stamp 37 moved backwards and contacted the s...

Embodiment 3

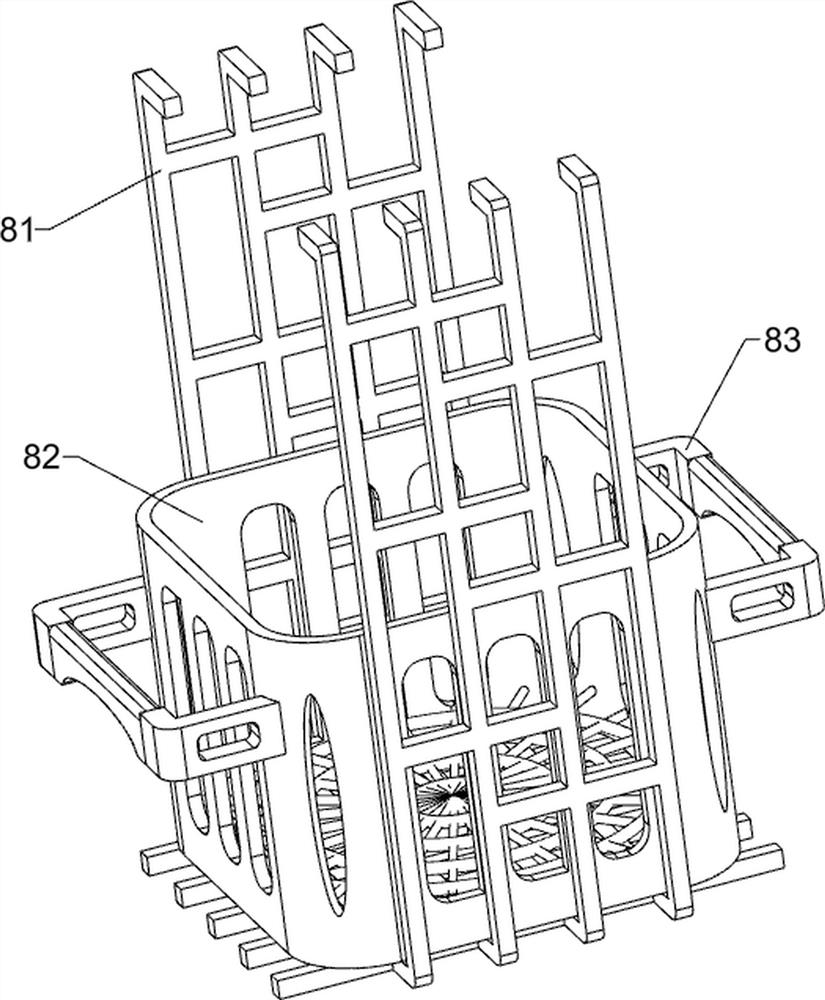

[0067] On the basis of Example 2, such as Figure 6 to Figure 8 As shown, a blanking mechanism 6 is also included, and the blanking mechanism 6 includes a gear set 61, a third support block 62, a first fixed rod 63, a third transmission assembly 64, a second missing gear 65, and a second fixed rod 66 , rack bar 67 and the 4th spring 68, the 3rd support block 62 is provided with the front side of the first support frame 1 top, the 3rd support block 62 left side is connected with the first fixed rod 63, the first fixed rod 63 tops and A gear set 61 is connected between the transmission shafts of the second transmission assembly 33, a third transmission assembly 64 is connected between the gear set 61 and the top of the third support block 62, and a second transmission assembly 64 is connected to the right side of the transmission shaft of the third transmission assembly 64. Missing gear 65, the rear side of the first support frame 1 is connected with a second fixed rod 66, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com