A control strategy for electric drive dump truck braking system

A braking system and control strategy technology, applied in the direction of brakes, braking transmissions, vehicle components, etc., can solve the problems of increasing braking reaction time, increasing energy consumption, complex braking system, etc., to shorten the reaction time, increase the Service life, effect of simplified braking system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described below in conjunction with the accompanying drawings and specific embodiments.

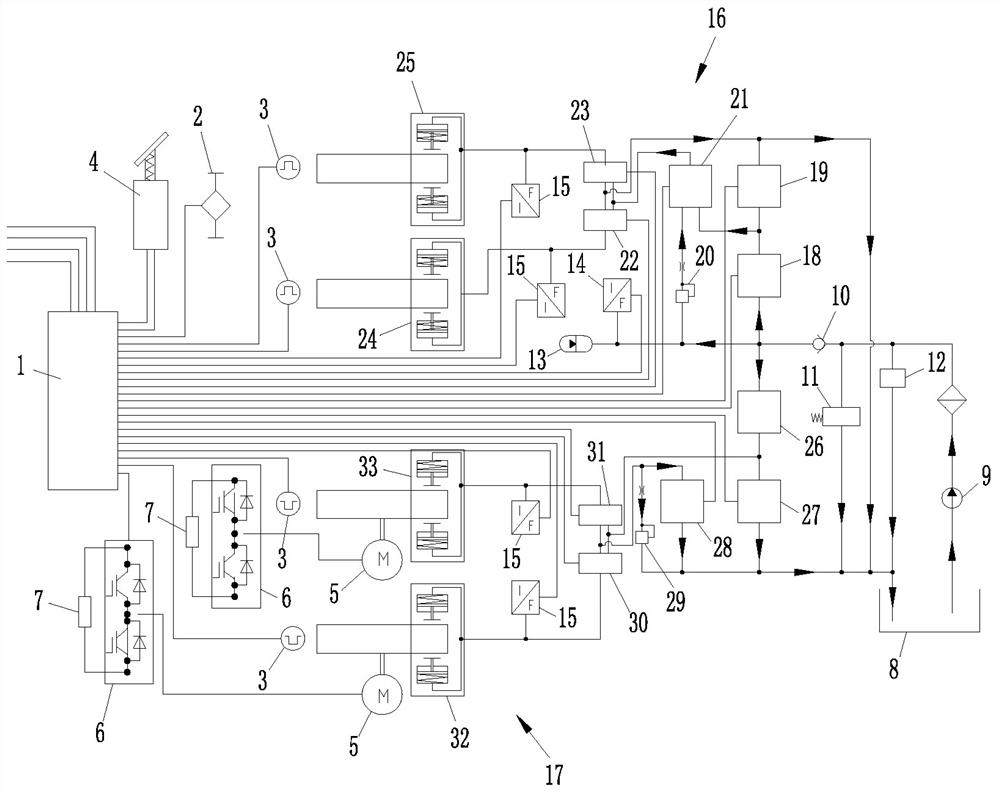

[0028] Such as figure 1 As shown, a control strategy for the braking system of an electric drive dump truck. The dump truck includes two front wheels and two rear wheels. The braking system includes a control module and a braking module. The braking module includes a An electric brake unit for applying braking force individually and a hydraulic brake unit for applying braking force individually to each wheel.

[0029] The control module collects the dump truck information and the driver's control signal and controls the brake module to work. The control module includes a control unit 1, a load sensor 2, a speed sensor 3 corresponding to a single wheel and a brake pedal 4.

[0030] The electric braking unit includes two generators 5 respectively arranged at the two rear wheels, a converter 6 connected to the output ends of the generators 5 and a brakin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com