Degradable environment-friendly plastic bag and preparation method thereof

A plastic bag, environmental protection technology, applied in the field of plastic bags, can solve the problems of uneven mechanical properties of biodegradable plastics, uneven dispersion of plant fiber starch, poor mechanical properties of plastic bags, etc., to achieve excellent isotropy and improve aesthetics and recognition, and the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

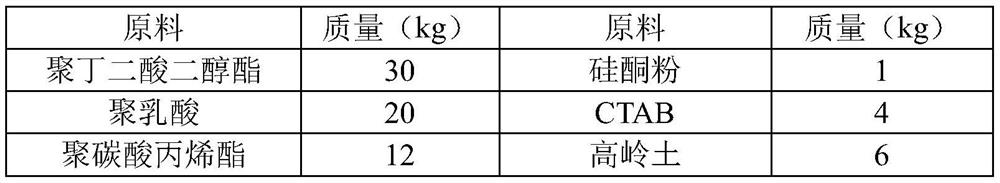

[0041] Table 1 is the raw material and weight of a kind of degradable environmental protection plastic bag of embodiment 1

[0042]

[0043]

[0044] Wherein, the preparation method of modified silicon dioxide is:

[0045] 1) Disperse 5kg of silicon dioxide in 20kg of absolute ethanol to obtain a suspension;

[0046] 2) Add 0.2kg of silane coupling agent to an aqueous alcohol solution with a pH of 3 for ultrasonic hydrolysis for 1 h. The silane coupling agent is aminopropyltriethoxysilane, and the aqueous alcohol solution is a mixed solution of absolute ethanol and deionized water and The volumes of absolute ethanol and deionized water are 5L respectively;

[0047] 3) Add the hydrolyzed silane coupling agent in step 2) to the suspension in step 1) at 60°C, then adjust the pH of the solution to 10, continue stirring for 3 hours, filter, wash and dry to obtain Modified silica.

[0048] A preparation method of a degradable environmental protection plastic bag, specifical...

Embodiment 2

[0054] Embodiment 2, the difference between this embodiment and embodiment 1 is:

[0055] The preparation method of modified silicon dioxide is:

[0056] 1) Disperse 5kg of silicon dioxide in 25kg of absolute ethanol to obtain a suspension;

[0057] 2) Add 0.5 kg of silane coupling agent to an aqueous alcohol solution with a pH of 4 for ultrasonic hydrolysis for 1 h. The silane coupling agent is trimethylethoxysilane, and the aqueous alcohol solution is a mixed solution of absolute ethanol and deionized water without The volumes of water ethanol and deionized water are 5L respectively;

[0058] 3) Add the hydrolyzed silane coupling agent in step 2) to the suspension in step 1) at 70°C, then adjust the pH of the solution to 11, continue stirring for 4 hours, filter, wash and dry to obtain Modified silica.

Embodiment 3

[0059] Embodiment 3, the difference between this embodiment and embodiment 1 is:

[0060] Wherein, the preparation method of modified silicon dioxide is:

[0061] 1) Disperse 5kg of silicon dioxide in 30kg of absolute ethanol to obtain a suspension;

[0062] 2) Add 0.8 kg of silane coupling agent to an aqueous alcohol solution with a pH of 3.5 for ultrasonic hydrolysis for 1 h. The silane coupling agent is aminopropyltriethoxysilane, and the aqueous alcohol solution is a mixed solution of absolute ethanol and deionized water and The volumes of absolute ethanol and deionized water are 5L respectively;

[0063] 3) Add the hydrolyzed silane coupling agent in step 2) to the suspension in step 1) at 70°C, then adjust the pH of the solution to 10.5, continue stirring for 4 hours, filter, wash and dry to obtain Modified silica.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap