A double-layer fabric quantitative yarn feeding device for carpet weaving

A technology of double-layer fabrics and feeding devices, which is applied in textiles, papermaking, looms, textiles, etc., can solve problems such as unsmooth feeding of yarns, uneven acceleration, and affecting work, so as to prevent prolapse, wear, and tear. The effect of preventing yarn loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

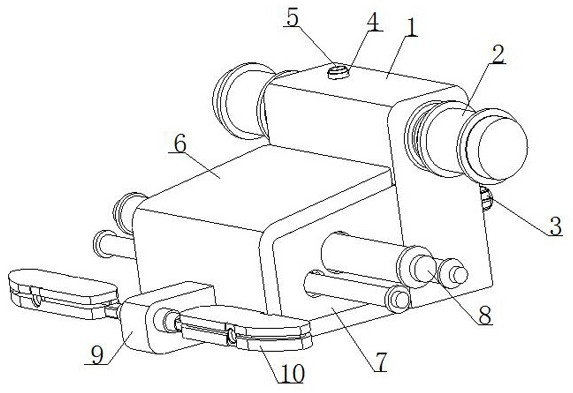

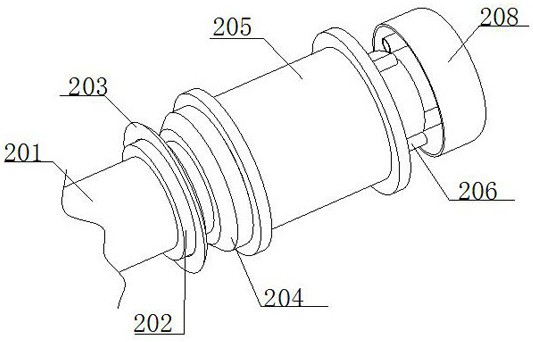

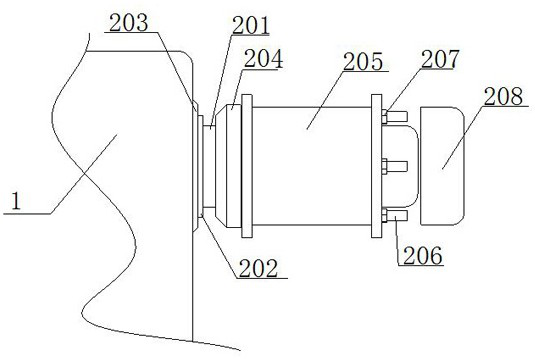

[0033] see Figure 1-4, the present invention provides a technical solution: a double-layer fabric quantitative yarn feeding device for carpet weaving, comprising a supporting block 1, a feeding device 2 is arranged inside the supporting block 1, and the outer wall of the feeding device 2 and the inner wall of the supporting block 1 are movable Connection, the inside of the feeding device 2 includes a yarn feeding shaft 201, the outer wall of the yarn feeding shaft 201 is movably mounted with a bearing 202, the outer wall of the bearing 202 is fixedly connected with the inner wall of the support block 1, and the outside of the bearing 202 is provided with a sealing ring 203, the sealing ring 203 The outer wall of the yarn feeding shaft 201 is fixedly connected with the outer wall of the yarn feeding shaft 201. The outer wall of the yarn feeding shaft 201 is fixedly installed with a fixing ring 204. One end of the fixing ring 204 is provided with a threaded rod 206. The inner w...

Embodiment 2

[0036] see Figure 1-6 , Based on the first embodiment, the present invention provides a technical solution: the outer wall of the connection block 6 is provided with a connection bump 9, one end of the connection bump 9 is fixedly connected with the outer wall of the connection block 6, and the outer wall of the connection bump 9 is provided with a guide The yarn device 10, the inside of the yarn guide device 10 includes a connecting seat 1001, one end of the connecting seat 1001 is fixedly connected with the outer wall of the connecting bump 9, the other end of the connecting seat 1001 is provided with a rotating shaft 1002, and one end of the rotating shaft 1002 is connected with the connecting seat The inner wall of 1001 is movably connected, the other end of the rotating shaft 1002 is fixedly installed with a connecting column 1003, the end of the connecting column 1003 away from the rotating shaft 1002 is provided with a bottom plate 1004, the outer wall of the bottom pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com