Construction method of high fill subgrade adjacent to dam

A construction method and high fill technology, which can be used in infrastructure engineering, roads, roads, etc., and can solve problems such as insufficient settlement time for dynamic compaction and reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

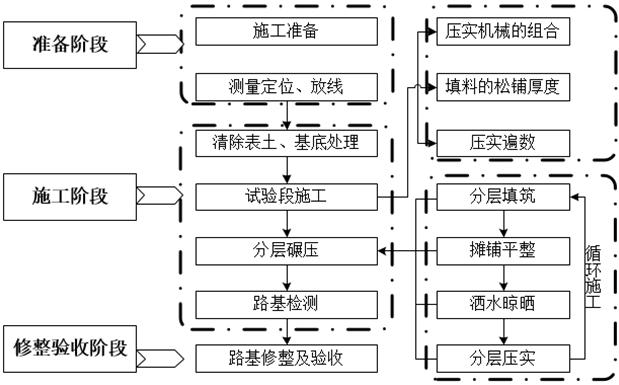

[0088] Such as figure 1 Shown: a kind of high fill embankment construction method adjacent to the dam, it comprises the following steps:

[0089] Step 1. Preparation for construction:

[0090] 1.1 Familiar with design documents and drawings, make technical disclosure and safety disclosure;

[0091] 1.2 According to the site situation, carry out labor allocation, equipped with good mechanical equipment and detailed entry and exit plan;

[0092] 1.3 Plan and design the access roads required in the process of subgrade filling, based on the convenience of transportation and not affecting the filling of subgrade earthwork, so as to ensure the smooth transportation of machinery and equipment during the process of earthwork backfilling;

[0093] 1.4 Do a good job of detailed earthwork allocation planning and overall layout, determine the filling section, leveling section, rolling section, and testing section, and gradually fill the construction in sections;

[0094] 1.5 Investigate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com