Aquaculture factory ship heat-preservation fishroom construction technology

A construction technique and fish tank technology, which is applied in fish farming, fishing boats, applications, etc., can solve the problems that the installation quality of the insulation layer cannot be guaranteed, and the construction process of the fish tank insulation layer is not standardized, so as to meet the construction specifications and ensure the construction quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following clearly and completely describes the technical solutions in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, but not all of them.

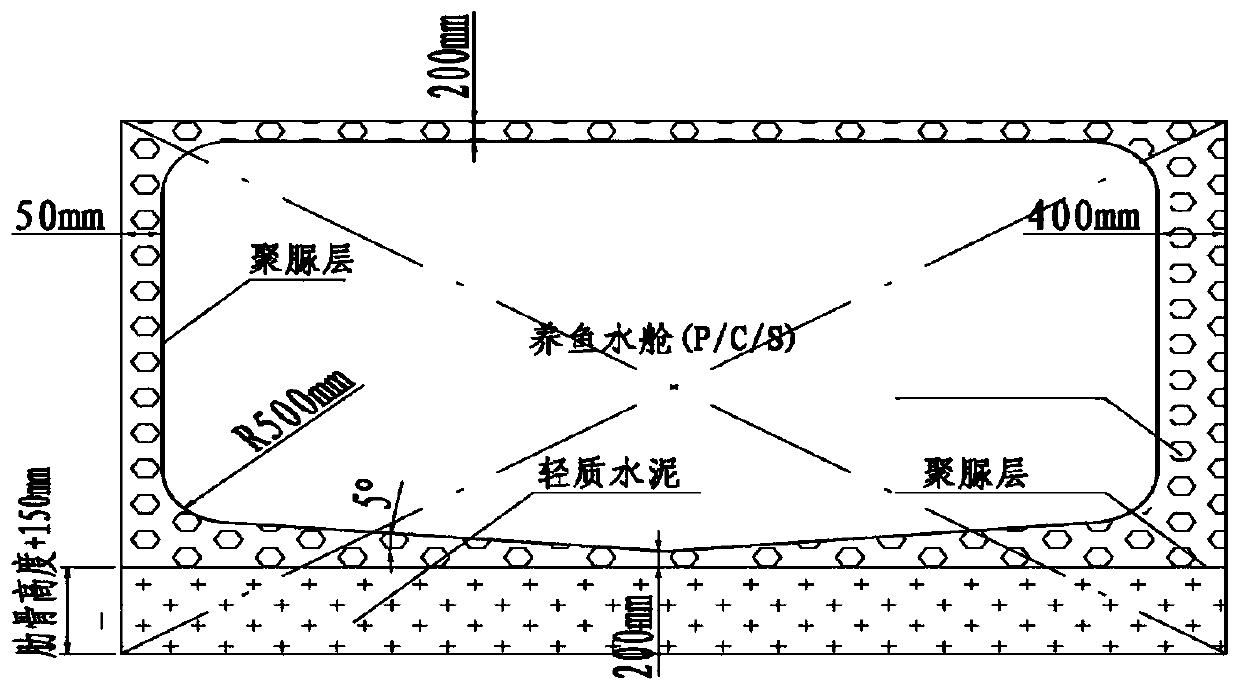

[0044] A construction process for the thermal insulation fish tank of a farming ship, comprising the following steps:

[0045] 1 Environmental conditions

[0046] 1.1 Ambient temperature -25℃~+55℃.

[0047] 1.2 Long-term seawater immersion.

[0048] 1.3 There are salt spray, oil spray and mold.

[0049] 2 materials

[0050] 2.1 Lightweight foamed cement: 32.5R ordinary Portland cement is generally used as cement, mixed with animal foaming agent. The dry bulk density per cubic meter is 300-400kg, and the compressive grade is ≥0.4MPa.

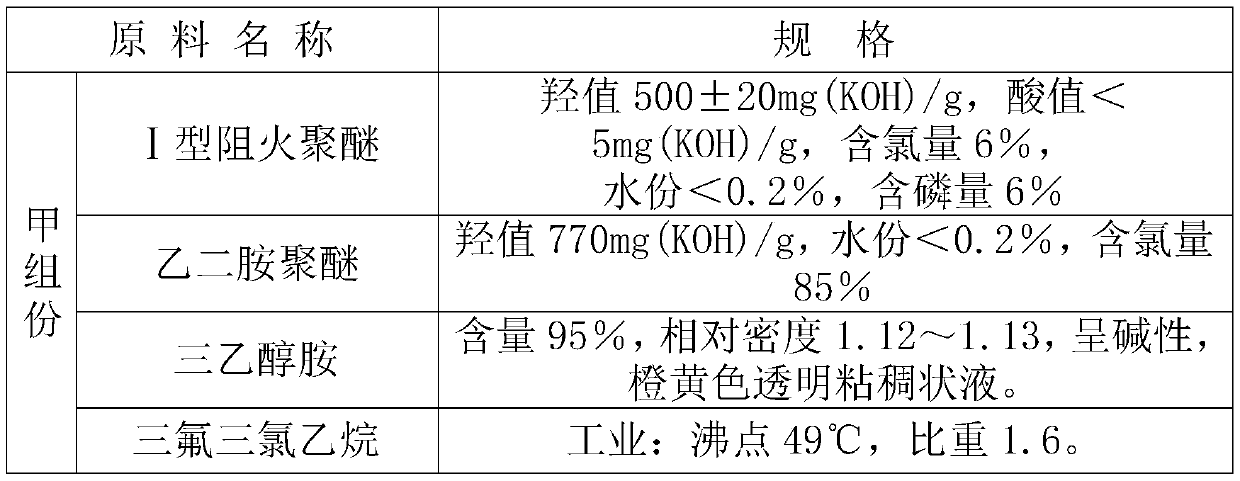

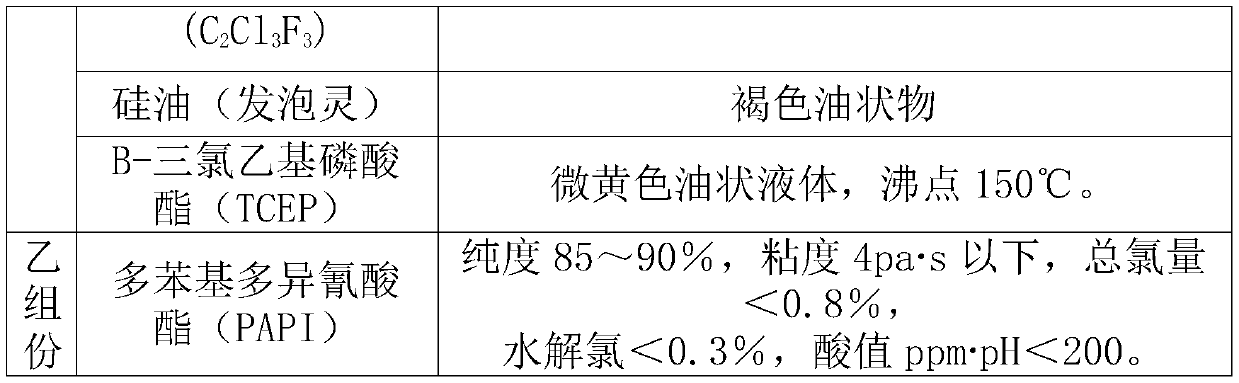

[0051] 2.2 Polyurethane: hard polyurethane plastic, see the table below for details:

[0052] Specifications of various raw materials required for on-site foaming construction of rigid polyurethane foam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com