Tailing pond drainage chute and drainage culvert combined plugging and drainage method

A technology for drainage chute and tailings pond, which is applied in the direction of waterway system, water supply device, sewer pipeline system, etc., to achieve the effects of strong operability, significant social and economic benefits, and low engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

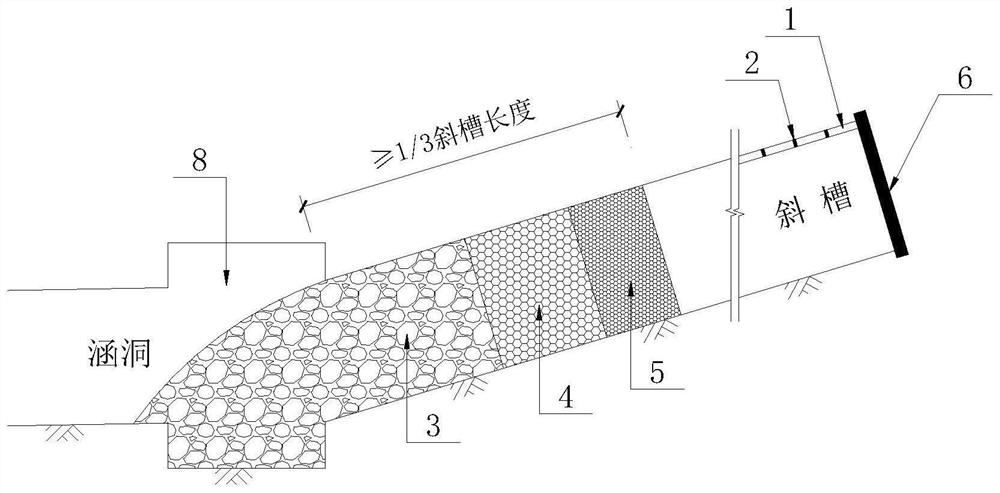

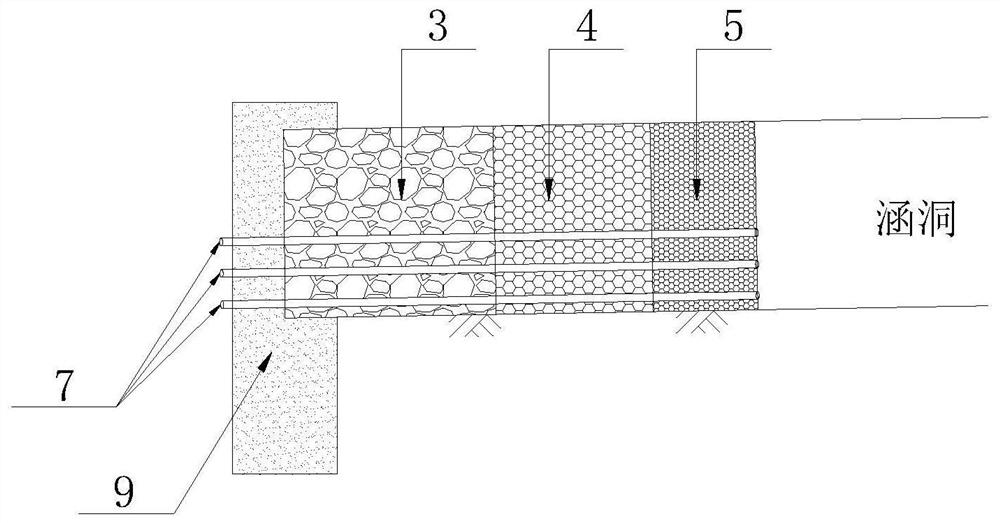

[0036]In order to better describe the present invention, the combined plugging and drainage method of the drainage chute and drainage culvert of the tailings pond of the present invention will be described in further detail below with reference to the accompanying drawings.

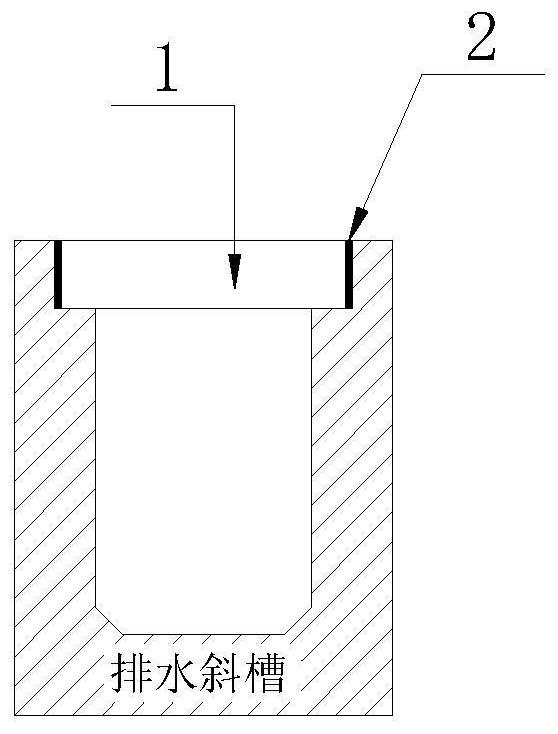

[0037]byfigure 1 The shown method of the present invention is combined with the structural cross-sectional view of the drainage chute plugging of the tailing pond flood drainage systemfigure 2 ,image 3It can be seen that the combined plugging and draining method of the drainage chute and drainage culvert of the tailings pond of the present invention is provided with a connecting well 8 between the drainage chute and the drainage culvert, and the following steps are adopted:

[0038]1) Blocking of drainage chute

[0039]The first step: First, cover all the chute cover plate 1 of the drainage chute, and adopt a specification of 400g / m2The non-woven geotextile 2 tightly fills the gap between the chute cover plate 1 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com