Aerated concrete plate steam curing cabin openable cabin door with configuration block

A technology of aerated concrete and block configuration, which is applied in the direction of windows/doors, window/door frames, window sills/thresholds, etc., which can solve the problems of wasting water resources and labor, unable to achieve uniformity, and unable to transport aerated concrete slabs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

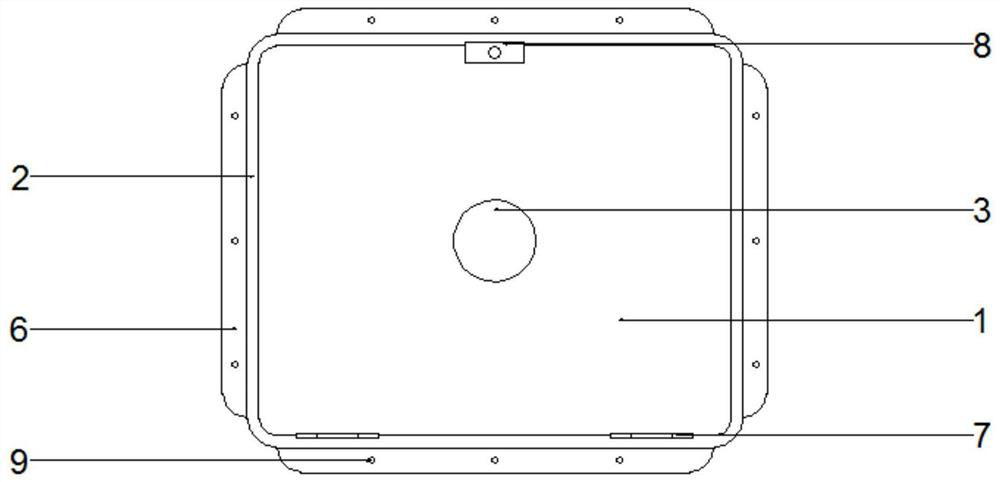

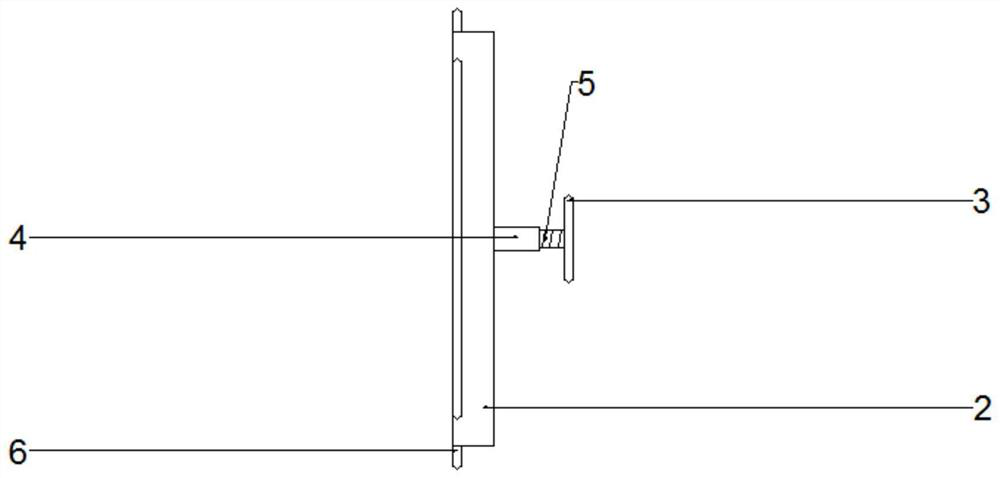

[0019] to combine figure 1 with figure 2 The openable hatch of the aerated concrete slab steam-curing warehouse with configuration blocks includes a rectangular frame-shaped door frame 2, and several flat-shaped mounting plates 6 are vertically arranged around the door frame 2, and several mounting plates 6 are arranged on the mounting plates 6. Hole 9, the door frame 2 is equipped with a hatch body 1, the bottom of the hatch body 1 is connected to the door frame 2 through a hinge 7, the top of the hatch body 1 is equipped with a lock catch 8 corresponding to the door frame 2, and the center of the outer wall of the hatch body 1 is vertical A round pipe-shaped threaded pipe 4 is provided, and the threaded pipe 4 is equipped with a threaded rod 5 fitted with a thread, and the end of the threaded rod 5 is provided with a flat configuration block 3 .

[0020] Both the door frame 2 and the mounting plate 6 are made of stainless steel, which are durable and have good corrosion re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com