Hybrid power control mechanism with three power sources

A technology of compound power and control mechanism, applied in the direction of engine components, mechanical equipment, valve operation/release devices, etc., can solve problems such as affecting product reliability and competitiveness, complex control system, and increasing maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention mainly utilizes the inventor of this case, and has previously proposed another invention design derived from the application number No. 108110801 "fluid transmission guiding control device and its application system" of the Taiwan invention patent application filed in China. To Chen Ming.

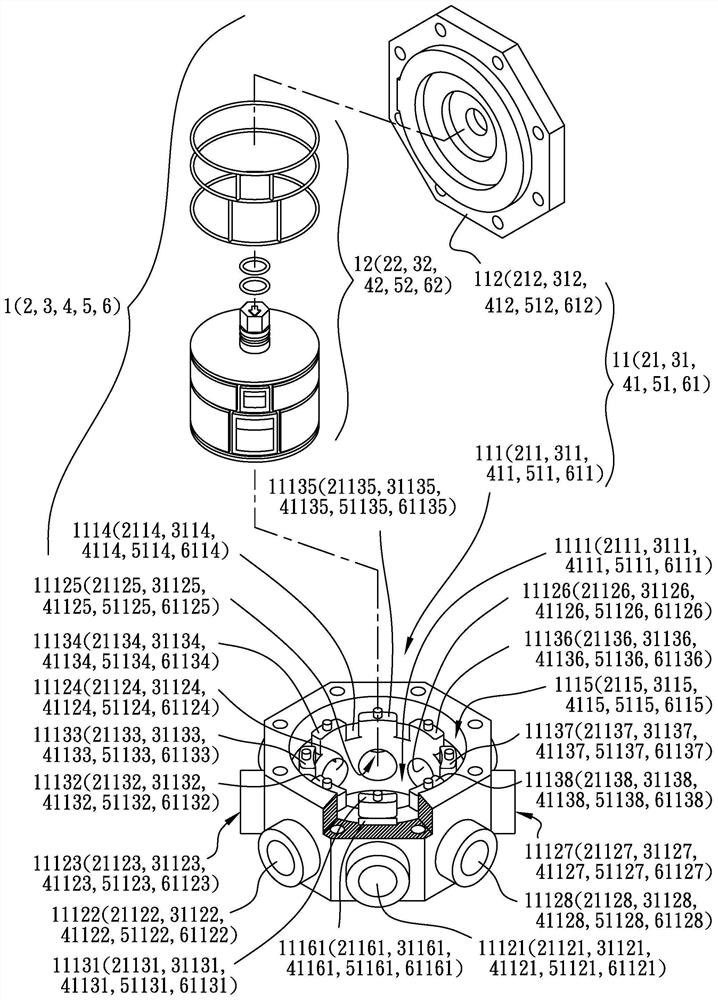

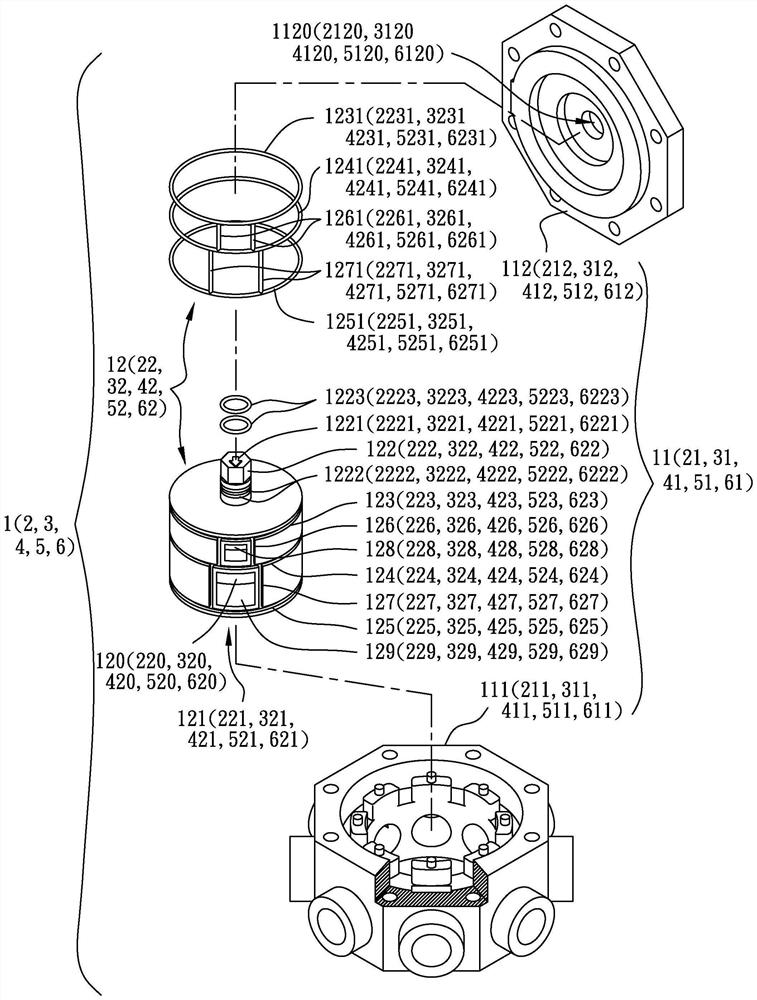

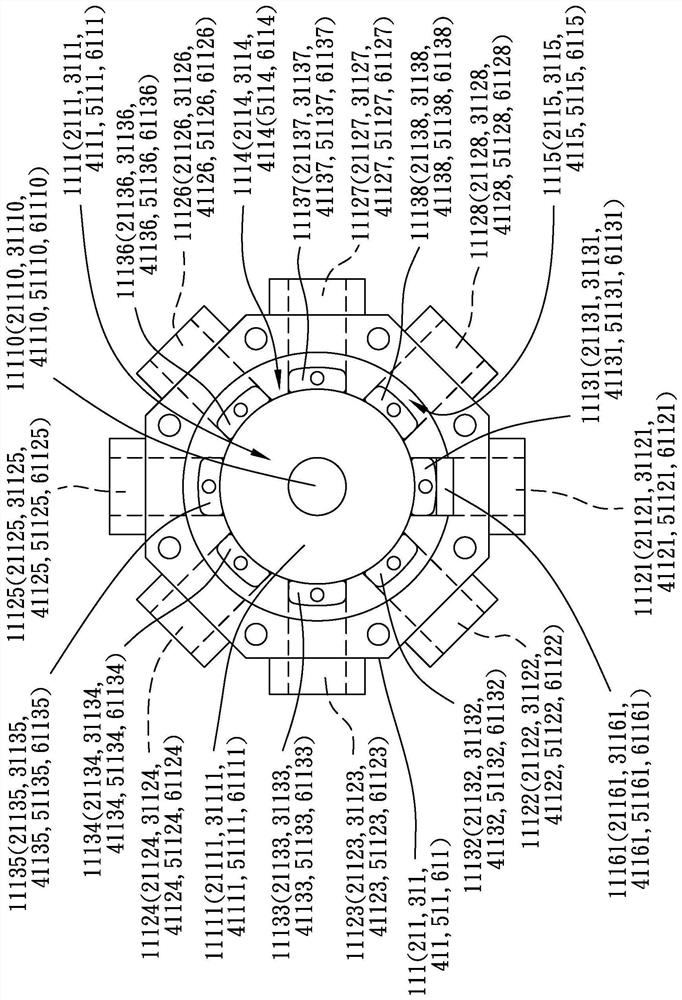

[0062] Please refer to Figure 11 , it can be seen that the overall structure of the present invention includes: a first control component 1, a second control component 2, a third control component 3, a fourth control component 4, a fifth control component 5 and a sixth control component 6; please refer to Figure 1 to Figure 11-1 As shown, each of the control assemblies 1, 2, 3, 4, 5, and 6 is composed of a power transmission and distribution unit 11, 21, 31, 41, 51, and 61 respectively combined with a switching member 12, 22, 32, and 42 , 52, 62; if the first control assembly 1 is taken as an example, it is composed of a first power transmission and distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com