Horizontal well multi-section multi-cluster limit flow-limiting fracturing process design method

A process design and horizontal well technology, applied in the field of horizontal well fracturing, can solve the problems of inability to achieve uniform stimulation, poor proppant laying effect, and low number of effective fractures, and achieve simple structure, increase in number, and improve perforation. The effect of eyelet friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

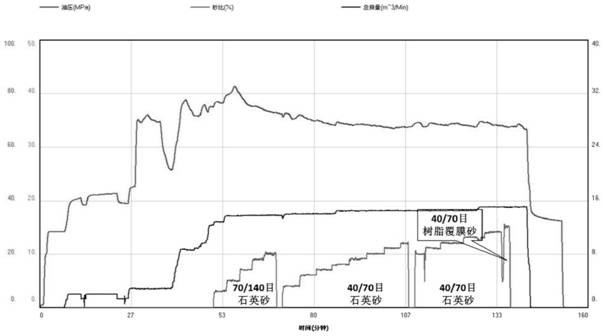

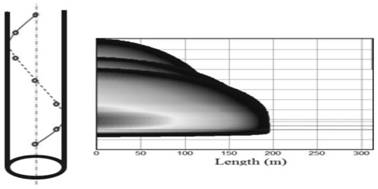

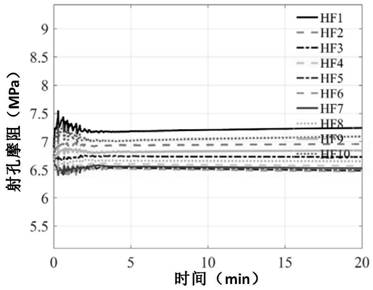

[0050] Such as Figure 1 to Figure 7 As shown, the multi-stage multi-cluster limit flow restriction fracturing process design method for horizontal wells includes the following steps:

[0051] (1) Collect geological parameters of horizontal wells including: reservoir depth, pore pressure, structural stress, mineral composition, etc., and establish corresponding geological models.

[0052] (2) Segment cluster spacing design: According to known geological and engineering parameters such as horizontal section traversal conditions, cementing conditions, and curvature development characteristics, the pressure field and stress field under different segment cluster spacings are simulated and calculated. Based on this, the calculation The optimal segment cluster spacing, try to reduce the segment cluster spacing within an appropriate range. According to the geological evaluation of different reservoir areas, the compressibility of the reservoir is further quantitatively calculated. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com