Gear box service life dynamic evaluation method and system based on digital twinning model

A dynamic evaluation and gearbox technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as research fatigue life, achieve a wide range of applications, improve efficiency, and avoid prediction deviations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below in conjunction with the specific embodiments shown in the accompanying drawings, but these embodiments do not limit the present invention, those of ordinary skill in the art make structural, method, or functional changes based on these embodiments All are included in the scope of protection of the present invention.

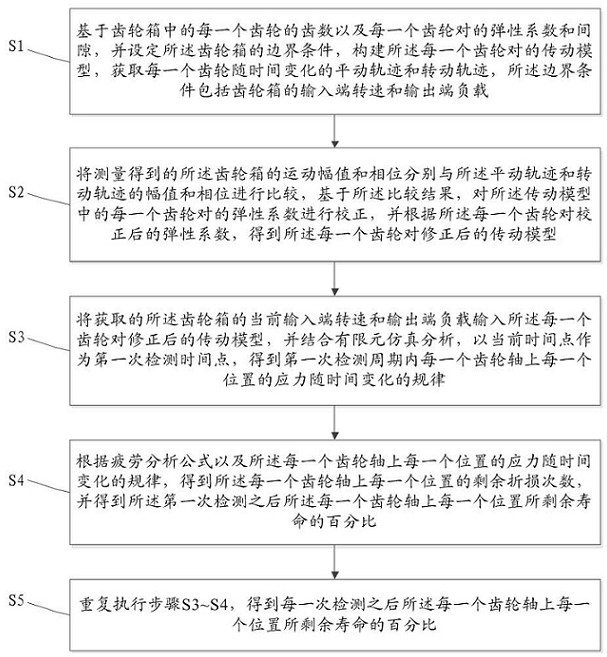

[0050] Such as figure 1 In one embodiment of the present invention shown, the present invention provides a method for dynamically evaluating the life of a gearbox based on a digital twin model, the method comprising:

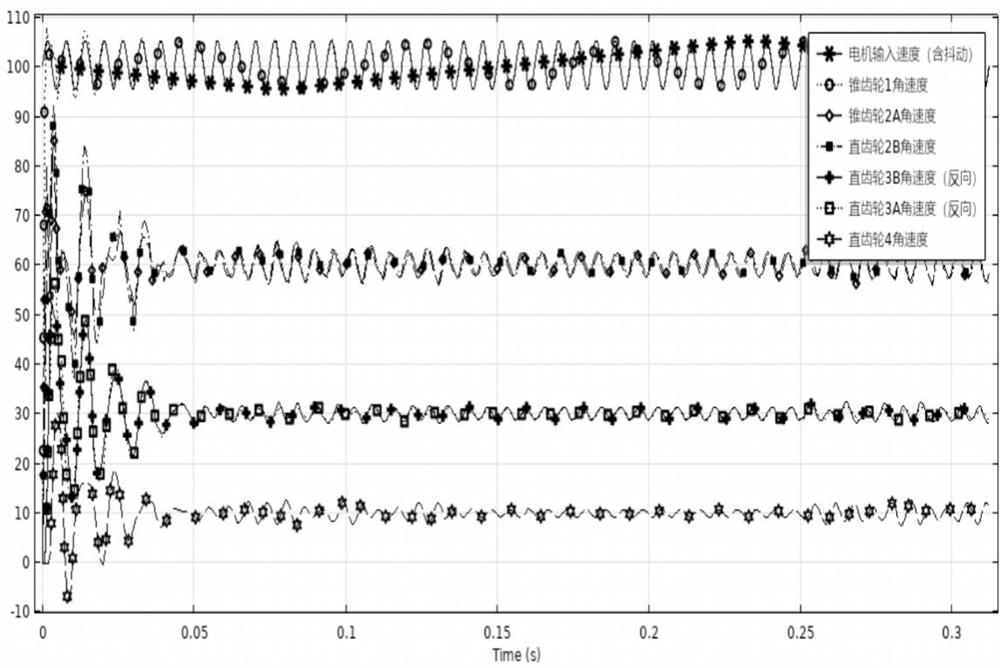

[0051] S1. Based on the number of teeth of each gear in the gearbox and the elastic coefficient and clearance of each gear pair, set the boundary conditions of the gearbox, construct the transmission model of each gear pair, and obtain each gear with Time-varying translational trajectory and rotational trajectory, the boundary conditions include the input speed and output load of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com