A b/mg co-doped high-nickel ternary precursor material, positive electrode material, and preparation method

A precursor and co-doping technology, applied in electrical components, battery electrodes, structural parts, etc., can solve problems such as high cost, increased process control difficulty, and disadvantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

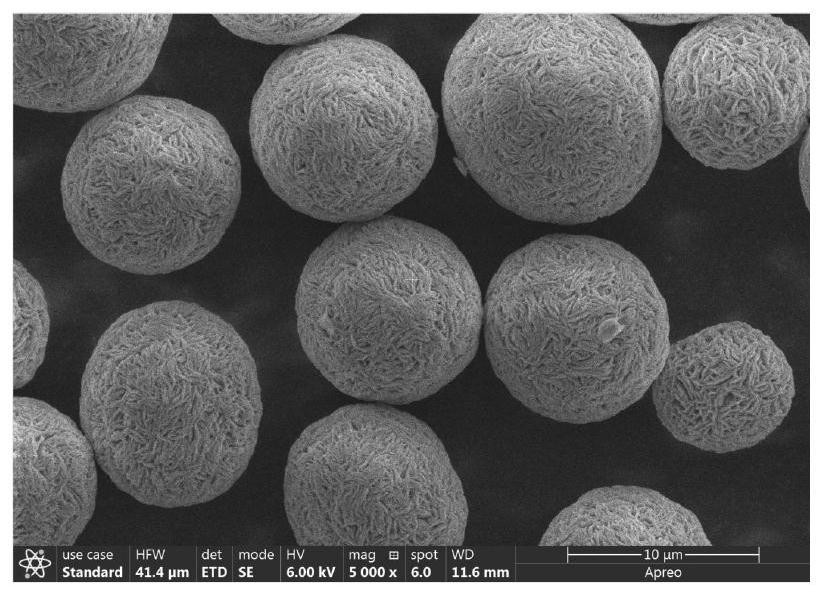

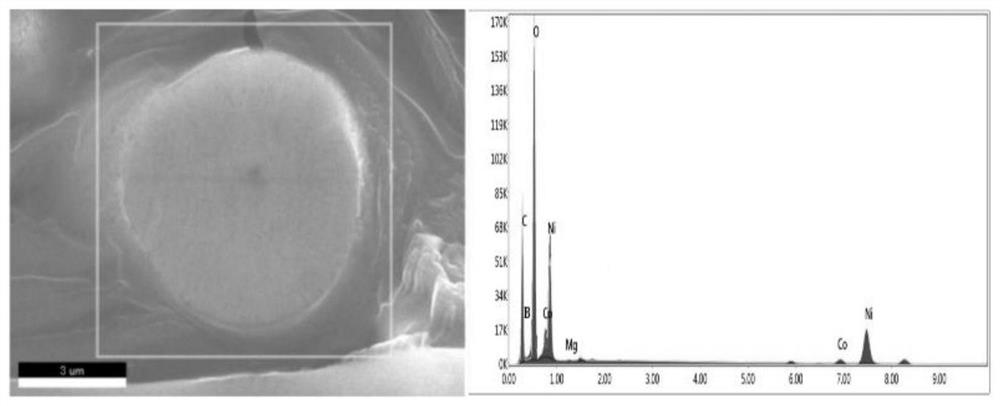

[0044] (1) NiSO 4 ·6H 2 O. CoSO 4 ·6H 2 O, MgSO4 ·6H 2 O and B 2 o 3 dissolved in water, the molar ratio of Ni:Co:Mg:B is 0.8:0.1:0.025:0.025, and the metal salt solution A is prepared. MgSO 4 ·6H 2 O and B 2 o 3 Dissolved in water to prepare solution B, the concentration of B and Mg in solution B is consistent with the concentration of B and Mg in solution A;

[0045] (2) Pass ammonia alkali into the reactor to control the initial pH to 11.8. Control the stirring speed at 500 r / min, start to pass through the metal salt solution A, and react until the average particle size is 4.3-5 μm. Reduce the stirring speed to 300 r / min, stop feeding metal salt solution A, and start feeding solution B (at the same flow rate). In an oven at ℃, the drying time is 2~4h, and the ternary precursor [Ni 0.8 co 0.1 Mg 0.05 B 0.05 ](OH) 2 ;

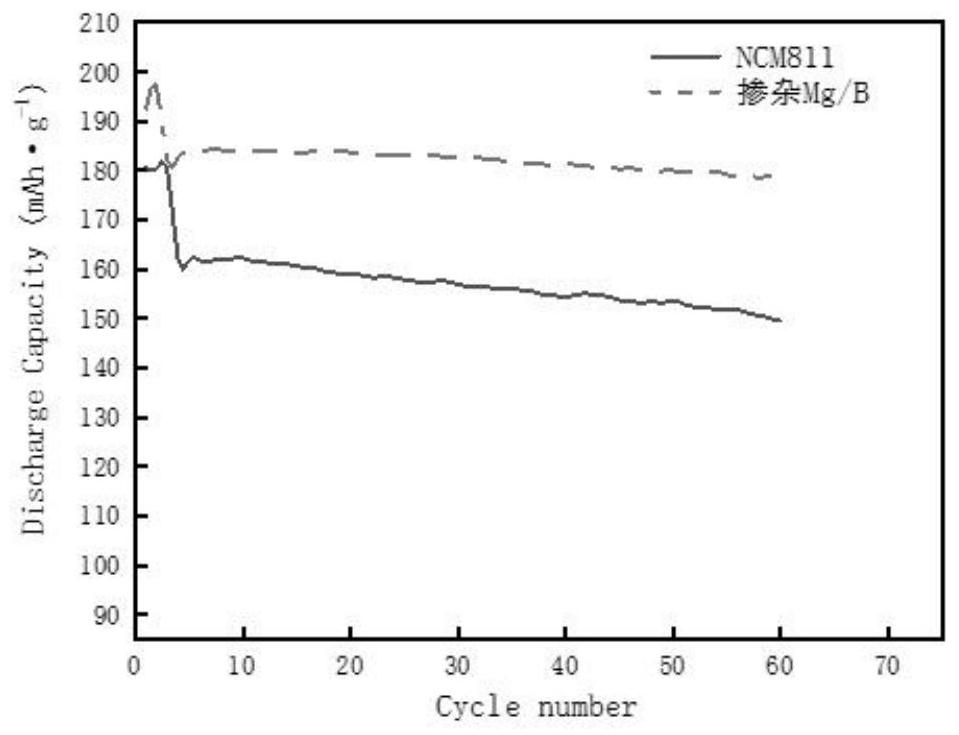

[0046] (3) The resulting ternary precursor [Ni 0.8 co 0.1 Mg 0.05 B 0.05 ](OH) 2 with LiCO 3 The molar ratio of Li:(Ni+Co+Mg+B) is (1~...

Embodiment 2

[0052] (1) NiNO 3 ·6H 2 O. CoNO 3 ·6H 2 O, MgSO 4 and B 2 o 3 dissolved in water, the molar ratio of Ni:Co:Mg:B is 0.8:0.1:0.0125:0.0375, and the metal salt solution A is prepared. MgSO 4 ·6H 2 O and B 2 o 3 Separately dissolved in water to prepare solution B, the concentration of B and Mg in solution B is consistent with the concentration of B and Mg in metal salt solution A;

[0053] (2) Pass ammonia alkali into the reactor to control the initial pH to 12.0. Control the stirring speed at 600 r / min, start to pass through the metal salt solution A, and react until the average particle size is 4.3~5 μm. Reduce the stirring speed to 400 r / min, stop feeding metal salt solution A, and start feeding solution B (at the same flow rate). In an oven at 160°C, the drying time is 2~4h, and the ternary precursor [Ni 0.8 co 0.1 Mg 0.025 B 0.075 ](OH) 2 ;

[0054] (3) The resulting ternary precursor [Ni 0.8 co 0.1 Mg 0.025 B 0.075 ](OH) 2 with LiCO 3 The molar ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com