Electrode material and secondary battery

A technology for electrode materials and secondary batteries, which is applied in the manufacture of secondary batteries, non-aqueous electrolyte batteries, and electrolyte batteries. It can solve problems affecting battery cycle performance and rate performance, and achieve both cycle stability and wettability. Effects of improved cycle life and rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

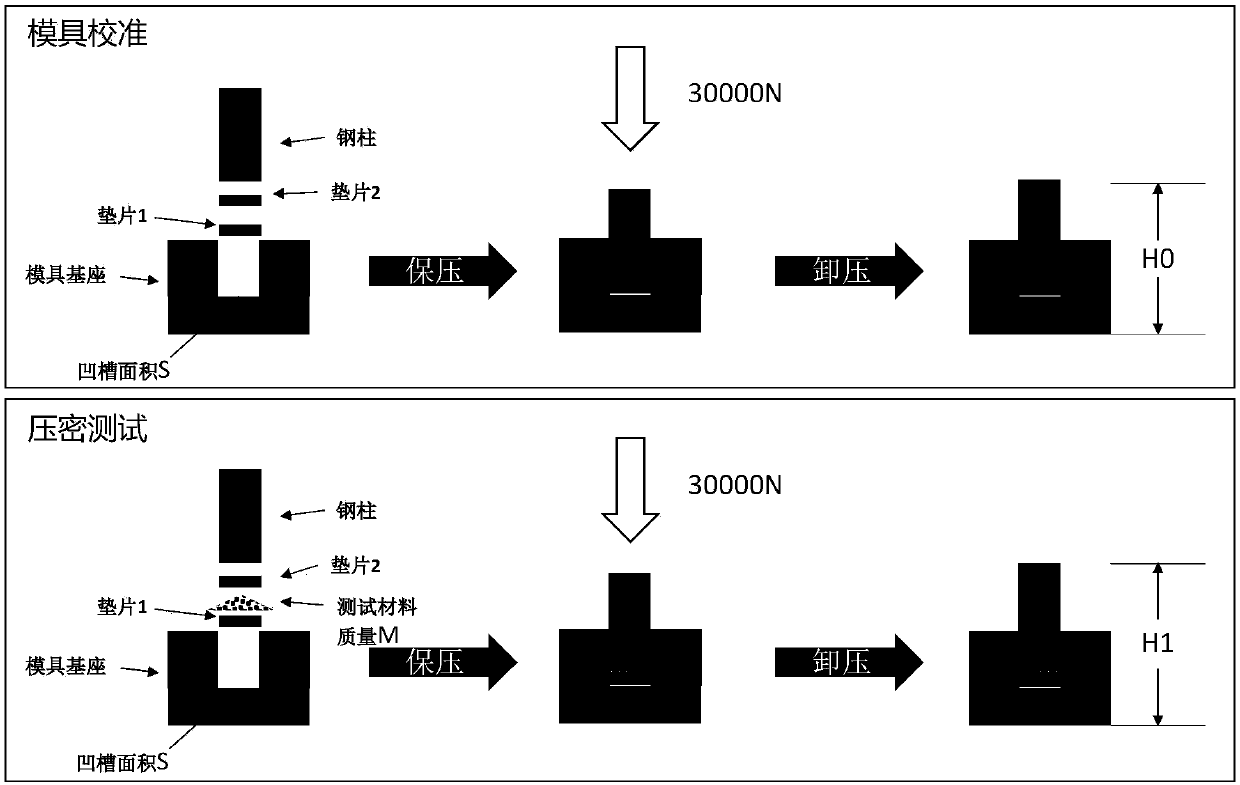

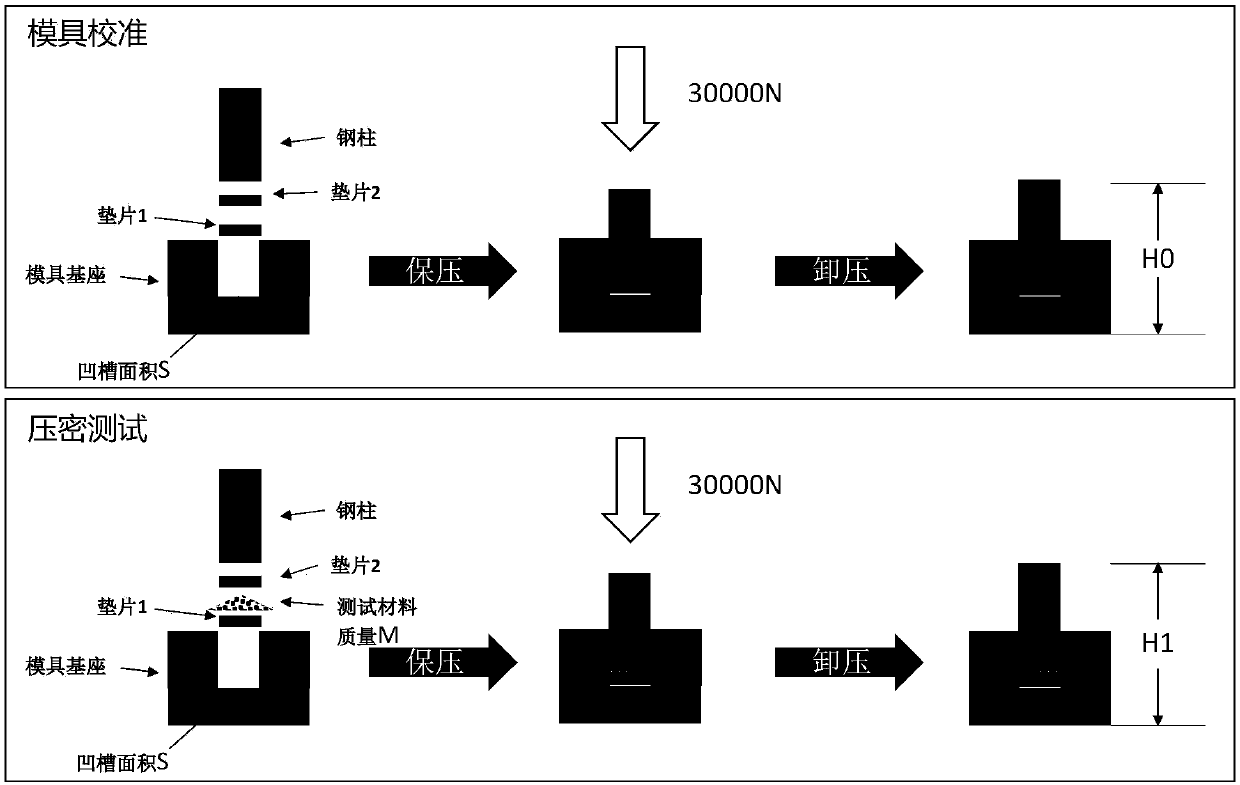

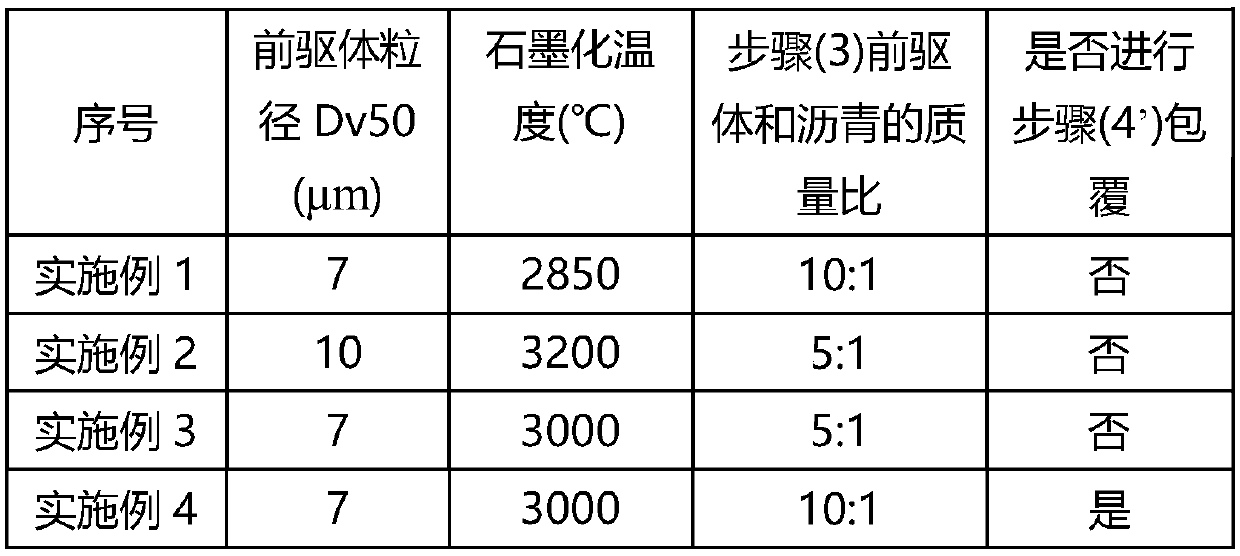

[0076] First, prepare the electrode material according to the specific process parameters (precursor particle size, graphitization temperature, etc.) listed in Table 1 according to "1. Preparation process of graphitized carbon electrode material", and then according to "2. Performance test" The graphitization degree, compacted density (30000N), gram capacity, rate performance and cycle performance of the obtained electrode materials were tested respectively, and the measured data are listed in Table 2.

Embodiment 2-6

[0078] The different process parameters listed in Table 1 were used to repeat Example 1 to prepare corresponding electrode materials, and the degree of graphitization, compaction density (30000N), gram capacity, and rate performance of the obtained electrode materials were tested respectively according to "two, performance test". And cycle performance, the measured data are listed in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com