B/Mg co-doped high-nickel ternary precursor material, positive electrode material and preparation method

A positive electrode material and co-doping technology, applied in the direction of electrical components, battery electrodes, electrochemical generators, etc., can solve the problems of increasing process control difficulty, air pollution, high cost, etc., to achieve easy industrial production, reduce side reactions, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

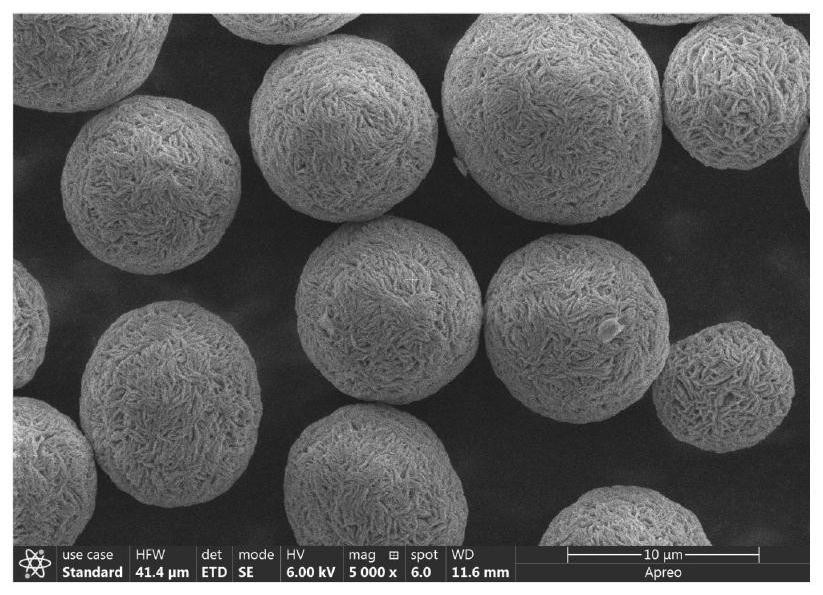

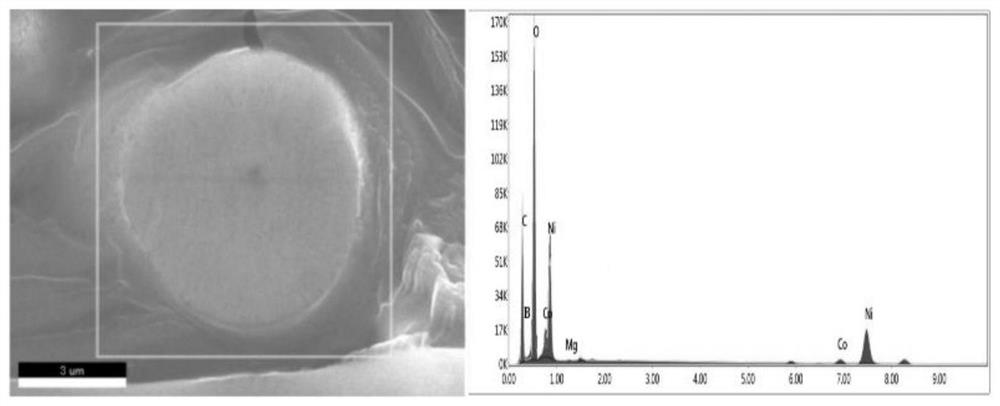

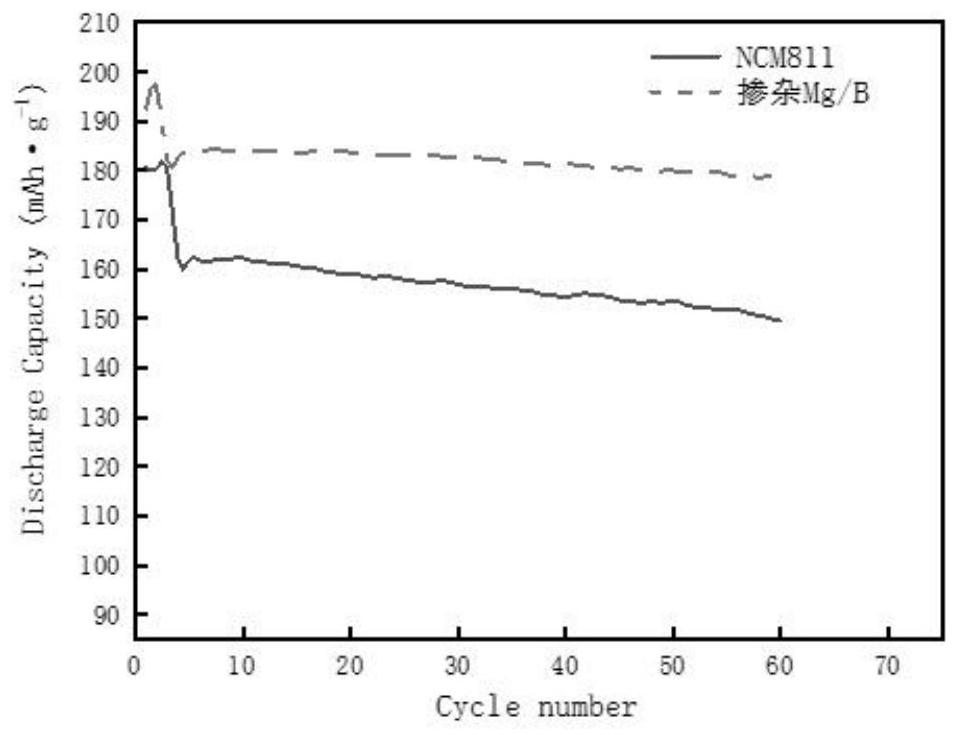

[0044] (1) NiSO 4 ·6H 2 O. CoSO 4 ·6H 2 O, MgSO4 ·6H 2 O and B 2 o 3 dissolved in water, the molar ratio of Ni:Co:Mg:B is 0.8:0.1:0.025:0.025, and the metal salt solution A is prepared. MgSO 4 ·6H 2 O and B 2 o 3 Dissolved in water to prepare solution B, the concentration of B and Mg in solution B is consistent with the concentration of B and Mg in solution A;

[0045] (2) Pass ammonia alkali into the reactor to control the initial pH to 11.8. Control the stirring speed at 500 r / min, start to pass through the metal salt solution A, and react until the average particle size is 4.3-5 μm. Reduce the stirring speed to 300 r / min, stop feeding metal salt solution A, and start feeding solution B (at the same flow rate). In an oven at ℃, the drying time is 2~4h, and the ternary precursor [Ni 0.8 co 0.1 Mg 0.05 B 0.05 ](OH) 2 ;

[0046] (3) The resulting ternary precursor [Ni 0.8 co 0.1 Mg 0.05 B 0.05 ](OH) 2 with LiCO 3 The molar ratio of Li:(Ni+Co+Mg+B) is (1~...

Embodiment 2

[0052] (1) NiNO 3 ·6H 2 O. CoNO 3 ·6H 2 O, MgSO 4 and B 2 o 3 dissolved in water, the molar ratio of Ni:Co:Mg:B is 0.8:0.1:0.0125:0.0375, and the metal salt solution A is prepared. MgSO 4 ·6H 2 O and B 2 o 3 Separately dissolved in water to prepare solution B, the concentration of B and Mg in solution B is consistent with the concentration of B and Mg in metal salt solution A;

[0053] (2) Pass ammonia alkali into the reactor to control the initial pH to 12.0. Control the stirring speed at 600 r / min, start to pass through the metal salt solution A, and react until the average particle size is 4.3~5 μm. Reduce the stirring speed to 400 r / min, stop feeding metal salt solution A, and start feeding solution B (at the same flow rate). In an oven at 160°C, the drying time is 2~4h, and the ternary precursor [Ni 0.8 co 0.1 Mg 0.025 B 0.075 ](OH) 2 ;

[0054] (3) The resulting ternary precursor [Ni 0.8 co 0.1 Mg 0.025 B 0.075 ](OH) 2 with LiCO 3 The molar ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com