Elastic circuit board structure

A circuit board and flexible technology, applied in the directions of printed circuits, printed circuit components, electrical components, etc., can solve the problems of hindering the miniaturization of anti-shake actuators, occupying anti-shake actuators, and large differences in power consumption. , to reduce production cost and defect rate, reduce anti-shake power consumption, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1 (circuit board structure):

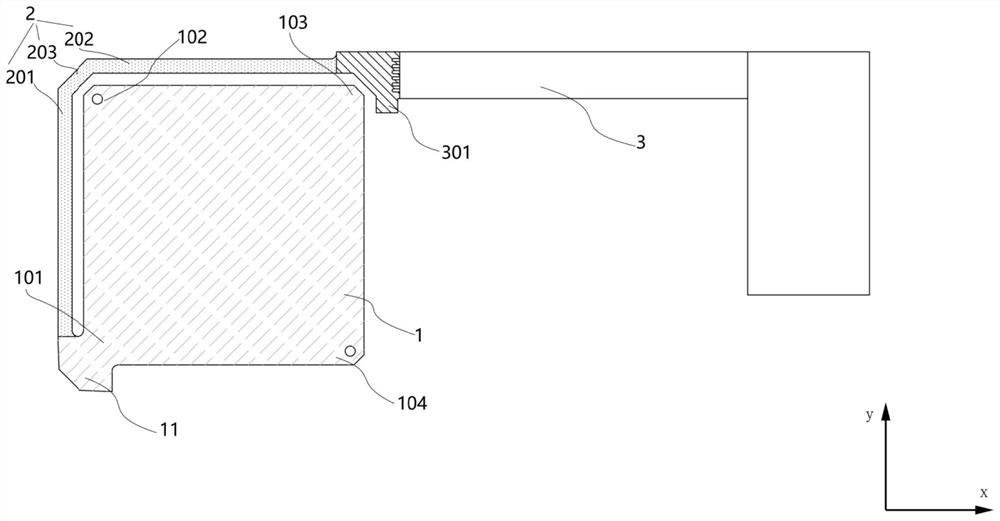

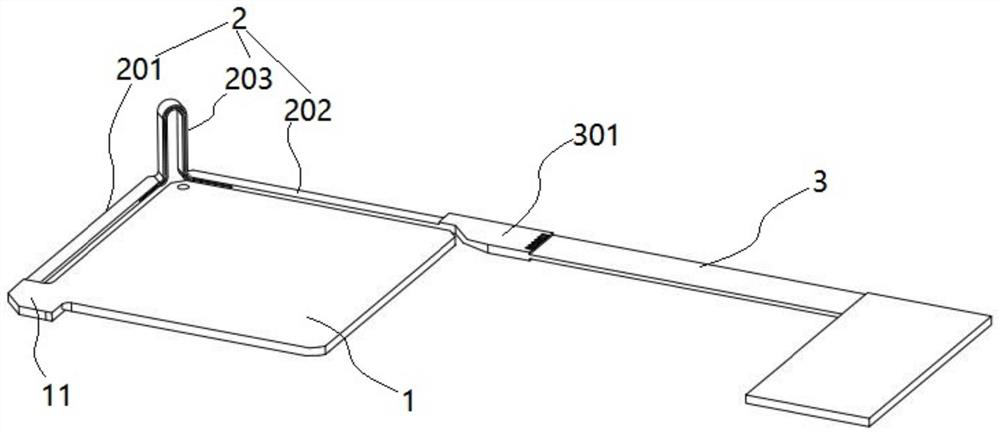

[0044] see figure 1 , the preferred embodiment of the present invention provides a flexible circuit board structure, including a movable carrier 1, an elastic connector 2 and a fixed carrier 3, the movable carrier 1 is provided with a movable connection part 11; each of the The elastic connector 2 includes a first connecting arm 201, a second connecting arm 202 and a bending part 203, one end of the first connecting arm 201 is connected to the movable connecting part 11, and the other end is connected to the bending part 203 connection; one end of the second connecting arm 202 is connected to the bending part 203; the horizontal angle between the first connecting arm 201 and the second connecting arm 202 is 45-135°; each of the A fixed connecting portion 301 is provided on the fixed carrier 3 , and the fixed connecting portion 301 is connected to the other end of the second connecting arm 202 .

[0045] Based on the above sche...

Embodiment 2

[0055] Embodiment 2 (circuit board structure):

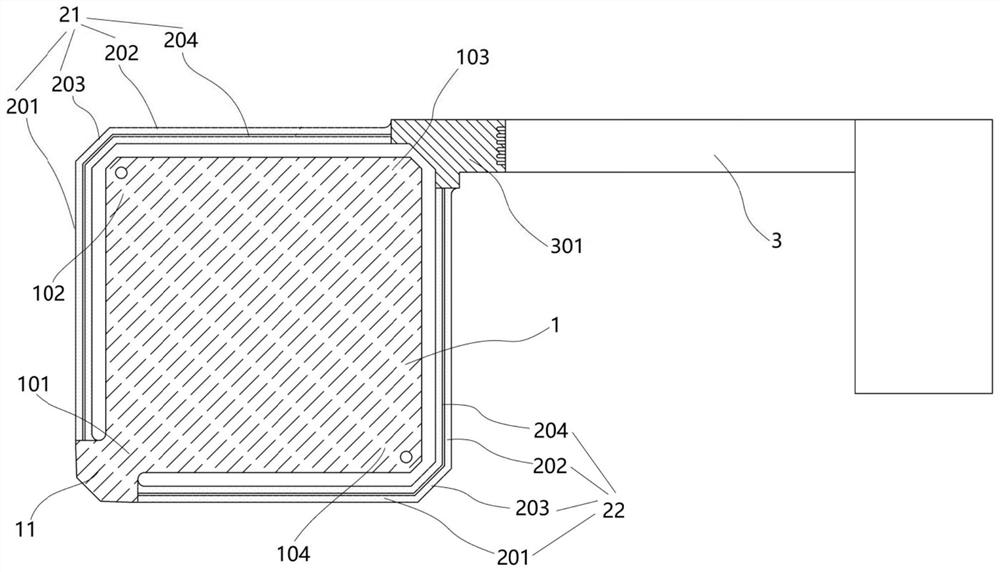

[0056] The structure of the embodiment of the present invention is basically the same as that of embodiment 1, and the only difference between them is: see image 3 In the embodiment of the present invention, two elastic connectors 2 are provided, which are the first elastic connector 21 and the second elastic connector 22 respectively. The second vertex 102 is set correspondingly, the bending part 203 of the second elastic connecting member 22 is set correspondingly to the fourth vertex 104 of the movable carrier 1 ; the first connecting arm 201 and the second connecting arm 202 are respectively parallel to the sides of the movable carrier 1 . Both the first elastic connection part 21 and the second elastic connection part 22 are connected to the movable connection part 11 and the fixed connection part 301 .

[0057] Based on the above scheme, the elastic circuit board structure of the embodiment of the present invention is n...

Embodiment 3

[0058] Embodiment 3 (circuit board structure):

[0059] The structure of the embodiment of the present invention is basically the same as that of embodiment 1, and the only difference between them is: see Figure 4 According to the embodiment of the present invention, there are two movable connecting parts 11, which are respectively a first movable connecting part 111 and a second movable connecting part 112, and the first movable connecting part 111 is arranged on the second movable connecting part 1 At a corner 101, the second movable connection part 112 is arranged at the third corner 103 of the movable carrier 1;

[0060] The fixed carrier 3 is provided with two, respectively the first fixed carrier 31 and the second fixed carrier 32, the fixed connection part 301 of the first fixed carrier 31 is connected with the first fixed carrier 1 of the movable carrier 1. The vertex 101 is arranged correspondingly, and the fixed connection part 301 of the second fixed carrier 32 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com