Optical arrangement and laser system

A technology of optical devices, laser beams, applied in the direction of optics, optical components, laser welding equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

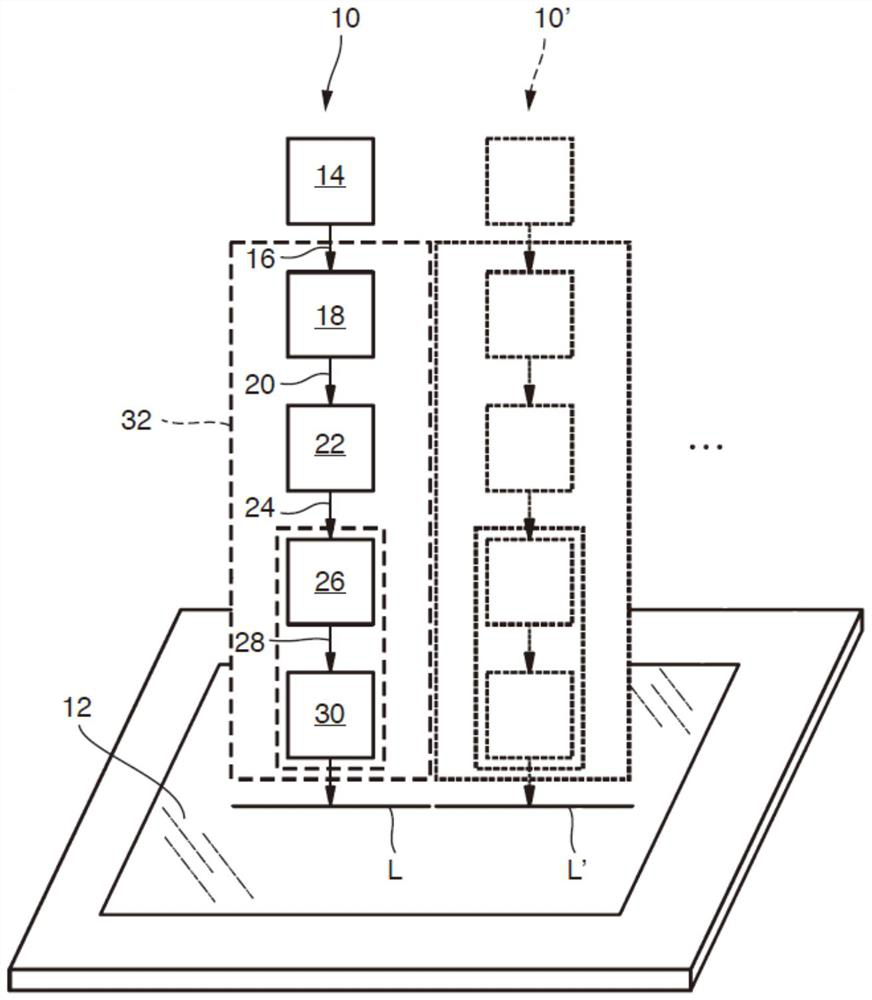

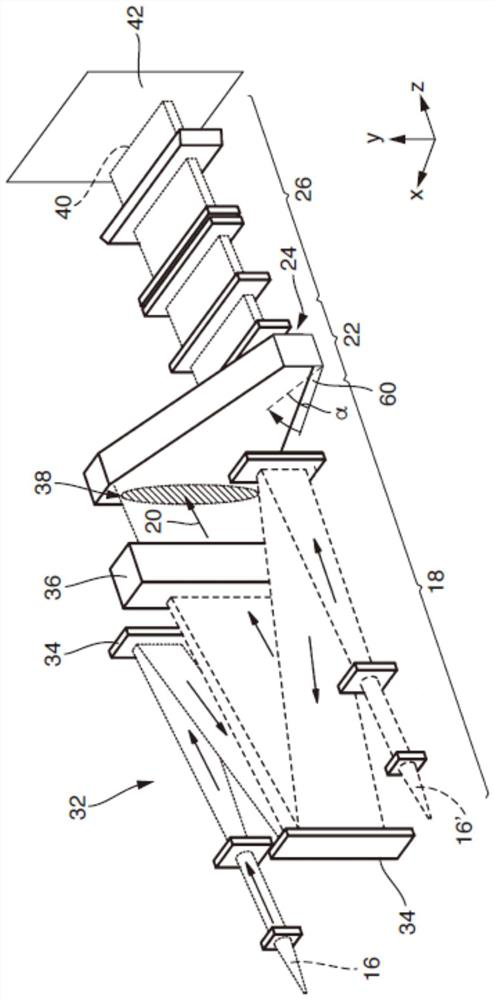

[0044] figure 1 is a schematic illustration of a laser system 10 for generating radiation with an intensity distribution L having a linear beam cross-section in the treatment plane 12 .

[0045] The laser system 10 includes at least one laser light source 14 for emitting laser radiation 16 . The laser light source 14 is preferably designed as a multimode laser. Laser radiation 16 optionally feeds an input laser beam 20 via a preshaping optical unit 18 . The preshaping optics unit 18 can, for example, have a collimating effect and / or shape the laser radiation 16 into an input laser beam 20 with an elliptical beam cross section.

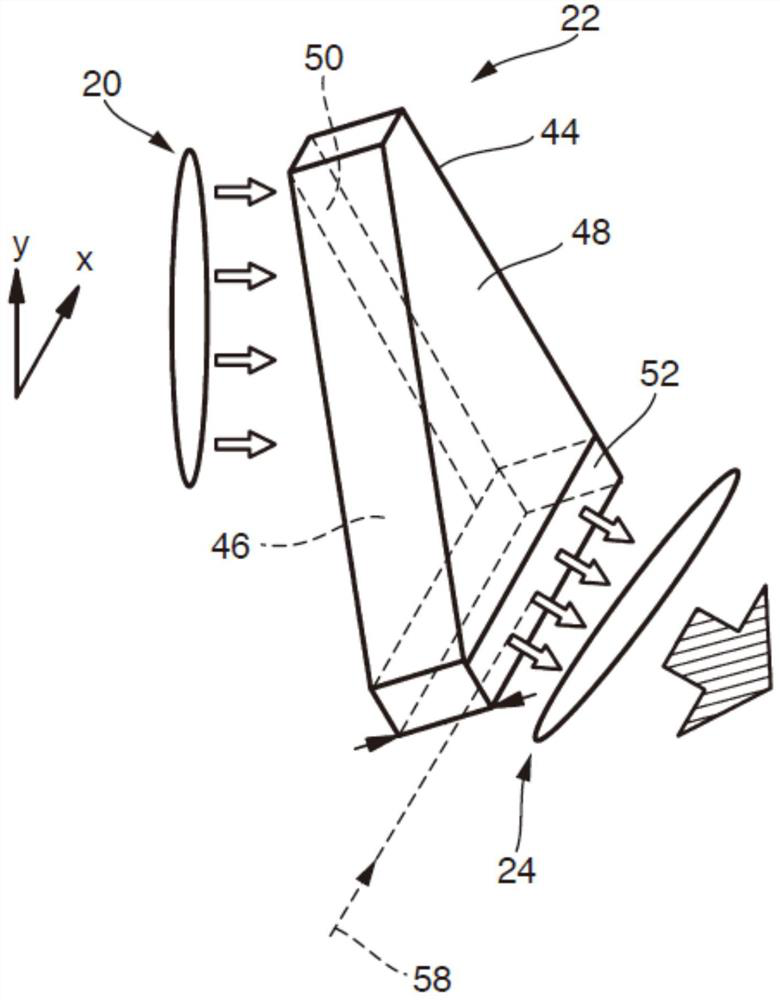

[0046] The input laser beam 20 is guided through a shaping optics unit 22 and emerges therefrom as a beam package 24 . The beam package 24 is converted into an output beam 28 by means of a homogenizing optical unit 26, as will be explained in more detail below. The output beam 28 can optionally be transformed into an intensity distribution L by mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com